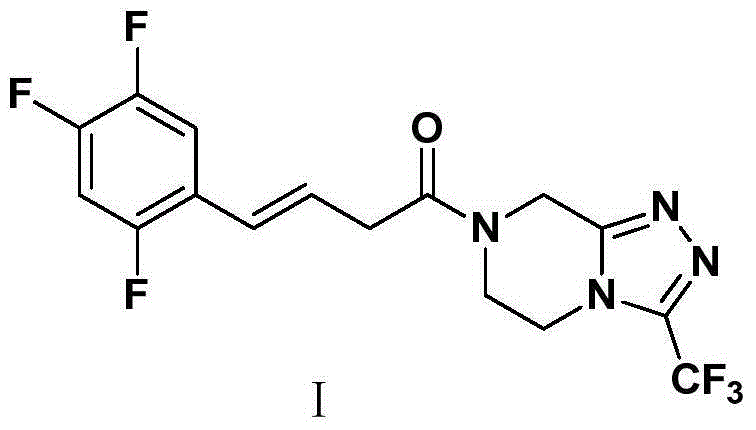

Sitagliptin impurity synthesis method

A sitagliptin impurity and synthesis method technology, applied in the field of sitagliptin impurity synthesis, can solve the problems of long route, complex reaction, low yield, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

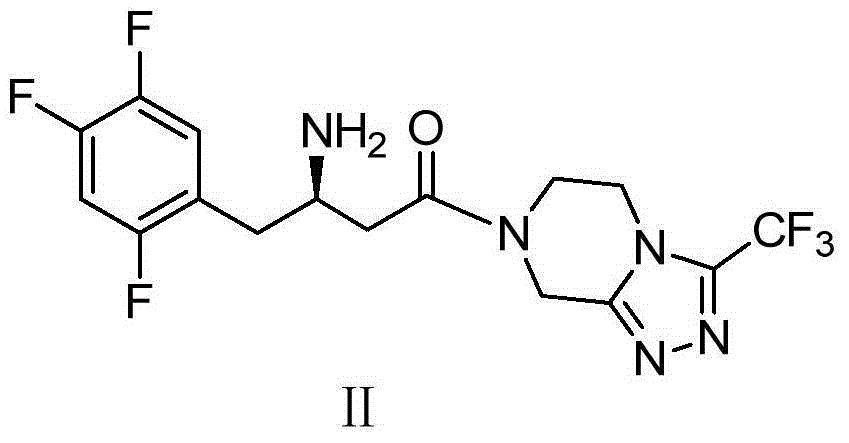

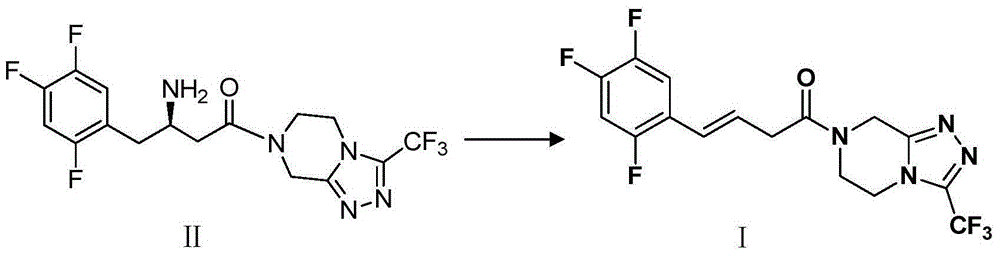

[0013] Embodiment 1: the preparation of sitagliptin impurity

[0014]

[0015] Put 5g of the compound shown in formula II into a 250ml three-neck flask, add 50ml of N,N-dimethylformamide, stir to dissolve, add 2ml of triethylamine, heat the system to 120°C, start the reaction, and track the reaction process by TLC , Reaction 12h. The system was cooled to room temperature, 100ml of water was added to the system, a white solid was precipitated, and the solid was filtered off to obtain 4.3g of sitagliptin impurity, with a yield of 91%.

Embodiment 2

[0017] Put 5g of the compound shown in formula II into a 250ml three-neck flask, add 50ml of N,N-dimethylacetamide, stir to dissolve, add 2ml of triethylamine, heat the system to 120°C, start the reaction, and track the reaction by TLC Process, reaction 12h. Cool the system to room temperature, add 100ml of ethyl acetate and 100ml of water to extract while stirring, wash the ethyl acetate layer with 100ml of saturated sodium chloride solution, dry the ethyl acetate solution with 5g of anhydrous sodium sulfate for 15-20min, and recover the solvent under reduced pressure get residue. The residue was dissolved in 50 ml, and 50 ml of n-hexane was added for crystallization to obtain 4.1 g of sitagliptin impurity as a solid, with a yield of 86%.

Embodiment 3

[0019] Put 5 g of the compound shown in formula II into a 250 ml three-neck flask, add 50 ml of toluene, stir to dissolve, 2 ml of triethylamine, heat the system to 110 ° C, reflux reaction, TLC detection to track the reaction process, and react for 24 hours. Cool the system down to room temperature, add 50ml of toluene and 100ml of water for extraction while stirring, wash the toluene layer with 100ml of saturated sodium chloride solution, dry the toluene solution with 5g of anhydrous sodium sulfate for 15-20min, and recover the solvent under reduced pressure to obtain a residue. The residue was dissolved in 50 ml, and 50 ml of n-hexane was added for crystallization to obtain 3.97 g of sitagliptin impurity as a solid, with a yield of 83%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com