High foaming polyethylene alloy material and preparation method therefor

A polyethylene and high-foaming technology, applied in the field of high-foaming polyethylene alloy material and its preparation, can solve problems such as insufficient hardness, and achieve the effects of high hardness and good cushioning and shock absorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

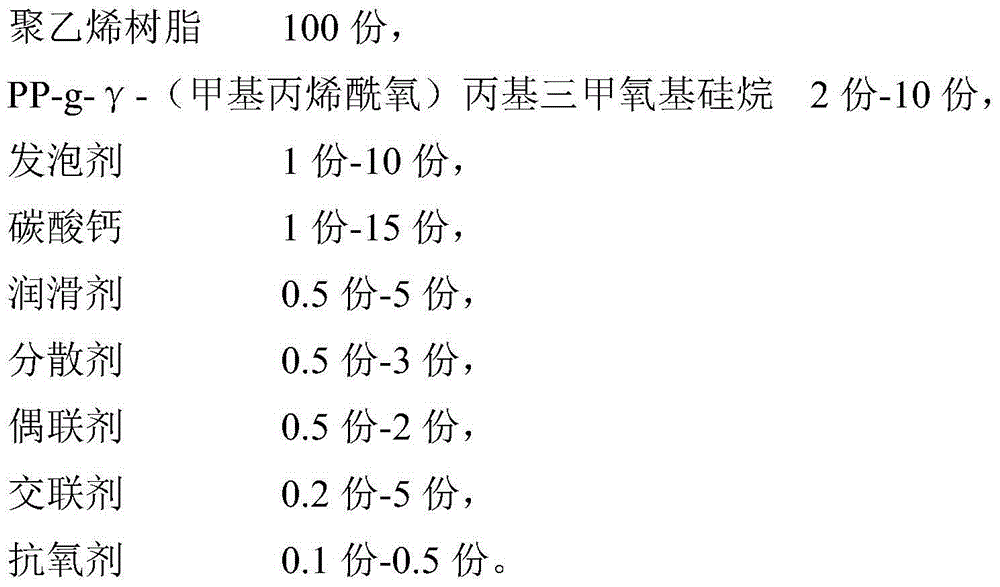

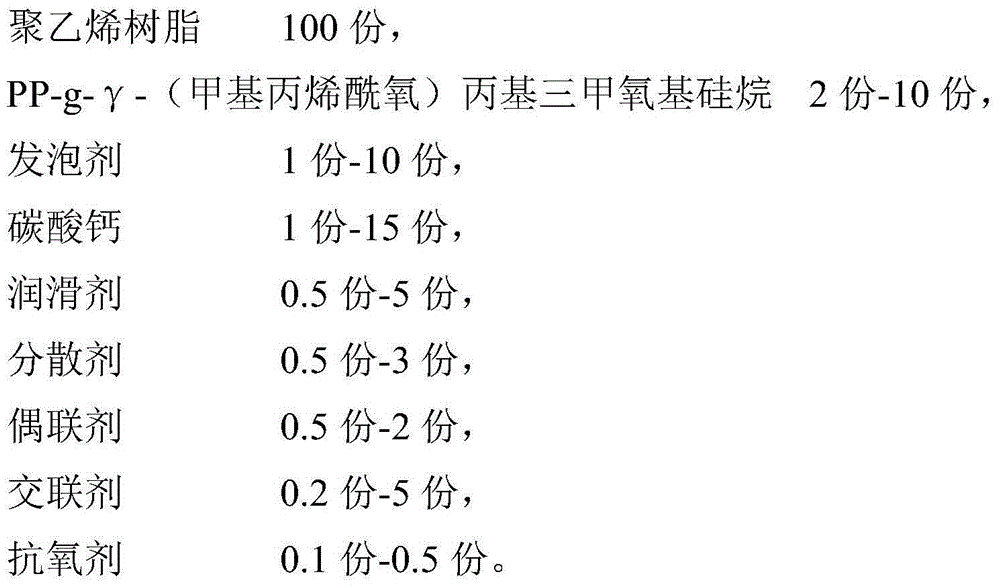

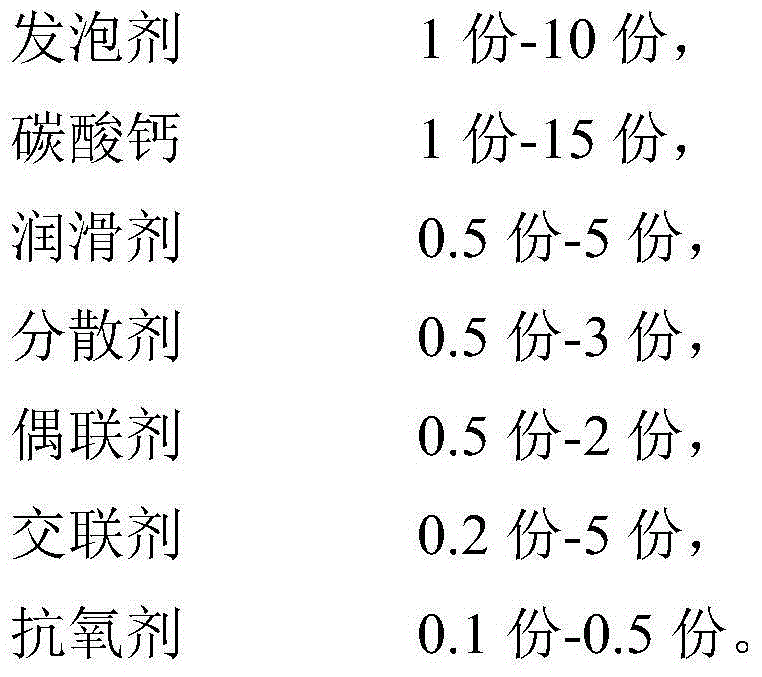

Method used

Image

Examples

preparation example Construction

[0041] A preparation method of high-foaming polyethylene alloy material, comprising the following preparation steps:

[0042] 1) The raw material components are weighed according to a certain weight ratio, and then added to the mixed product after mixing in the internal mixer. The mixing temperature is controlled at 150°C-160°C, and the mixing time is controlled at 5 minutes;

[0043] 2) Extrude and granulate the kneaded material in step 1) through a twin-screw extruder water rod to obtain a high-foaming polyethylene alloy material, wherein the extruder speed is set to 300rpm, and the six-stage processing temperature is set to 135°C, 140°C, 155°C, 160°C, 160°C, 155°C;

[0044] 3) The foamed alloy material prepared in step 2) is heated in a foaming mold, and then foamed and molded, wherein the foaming temperature is set at 200° C., and the foaming time is 10 minutes to 20 minutes.

[0045] The density of the foamed product made by the above steps is 0.05g / cm 3 -0.12g / cm 3 , ...

Embodiment 1

[0048]Weigh the following raw material components by weight: 100 parts of Fushun ethylene HDPE2911, 2 parts of PP1-g-γ-(methacryloyloxy)propyltrimethoxysilane, 10 parts of N,N-dinitrosopenta Methyltetramine, 1 part of light calcium carbonate, 5 parts of stearic acid, 0.5 part of oleic acid amide, 0.5 part of vinyltrimethoxysilane, 0.2 part of dicumyl peroxide (DCP), 0.1 part of 4,4 '-Thio(3-methyl-6-tert-butylphenol), and add the above raw material components into the internal mixer to knead the kneaded product, and control the kneading temperature at 150°C-160°C during kneading , the kneading time is controlled at 5 minutes; the kneaded material is extruded and granulated by twin-screw extruder water strands to obtain high-foaming polyethylene alloy material, the extruder speed is set to 300rpm, and the six-stage processing temperature is set to 135 ℃, 140°C, 155°C, 160°C, 160°C, 155°C; put the prepared high-foaming polyethylene alloy material in a foaming mold and heat it to...

Embodiment 2

[0050] Weigh the following raw material components by weight: 100 parts of Panjin Petrochemical LLDPE0209AA, 10 parts of PP1-g-γ-(methacryloyloxy)propyltrimethoxysilane, 10 parts of 4,4ˊ-oxidized dibenzenesulfonyl hydrazide , 5 parts of light calcium carbonate, 0.5 parts of PE wax, 3 parts of oleic acid amide, 2 parts of vinyltriethoxysilane, 5 parts of benzoyl peroxide (BPO), 0.5 parts of antioxidant 4,4'- Thio (3-methyl-6-tert-butylphenol), and the above-mentioned raw material components are added into an internal mixer and mixed to obtain a mixed product. During mixing, the mixing temperature is controlled at 150°C-160°C. The kneading time is controlled at 10 minutes; the kneaded material is extruded and granulated by a twin-screw extruder water rod to obtain a high-foaming polyethylene alloy material, wherein the extruder speed is set to 300rpm, and the six-stage processing temperature is set to 135°C, 140°C, 155°C, 160°C, 160°C, 155°C; the prepared high-foaming polyethyle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com