Glue used for transparent adhesive tape and preparation method of glue

A transparent tape and glue technology, applied in the direction of adhesives, film/sheet adhesives, non-polymer adhesive additives, etc., can solve the problems of viscosity change, peeling, residue, etc., and achieve a simple production process and good adhesion. Stability and low adhesive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Dissolve 20 parts by weight of konjac fly powder in ethanol, add 16 parts by weight of acrylate and 2 parts by weight of tackifying resin and mix evenly, adjust the pH of the mixed solution to 4.5, and then add 2 parts by weight of thiol containing ether structure Mix evenly, and finally add 0.2 parts by weight of leveling agent and mix evenly to obtain glue for scotch tape. The glue is coated on the base cloth of the BOPP film, the coating thickness is 25 microns, and the scotch tape is obtained after curing.

Embodiment 2

[0020] Dissolve 30 parts by weight of konjac powder in ethanol, add 24 parts by weight of acrylate and 5 parts by weight of tackifying resin and mix evenly, adjust the pH of the mixed solution to 5, and then add 4 parts by weight of thiol containing ether structure Mix evenly, and finally add 0.6 parts by weight of leveling agent and mix evenly to obtain glue for scotch tape. The glue is coated on the base cloth of the BOPP film with a coating thickness of 50 microns, and a scotch tape is obtained after curing.

Embodiment 3

[0022] Dissolve 40 parts by weight of konjac powder in ethanol, add 30 parts by weight of methacrylate and 8 parts by weight of tackifying resin and mix evenly, adjust the pH of the mixed solution to 5.5, and then add 7 parts by weight of ether-containing The mercaptan is mixed evenly, and finally 1 part by weight of a leveling agent is added and mixed evenly to obtain glue for scotch tape. The glue is coated on the base cloth of the BOPP film with a coating thickness of 30 microns, and a scotch tape is obtained after curing.

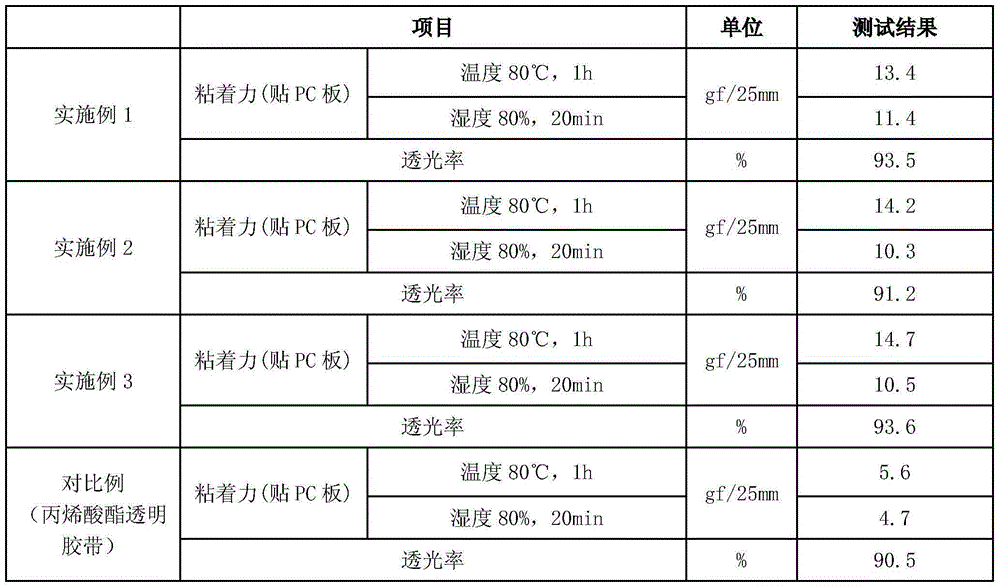

[0023] Table 1 Test data table of various physical properties of scotch tape

[0024]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com