Indirect pyrolysis system and a pyrolysis method thereof

A pyrolysis and indirect technology, applied in the field of coal pyrolysis, can solve the problems of small dust content of gas and tar, large dust content of gas and tar, poor quality of gas and tar, etc., so as to reduce dust content and increase furnace Effects of Temperature, Raise and Tar Quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

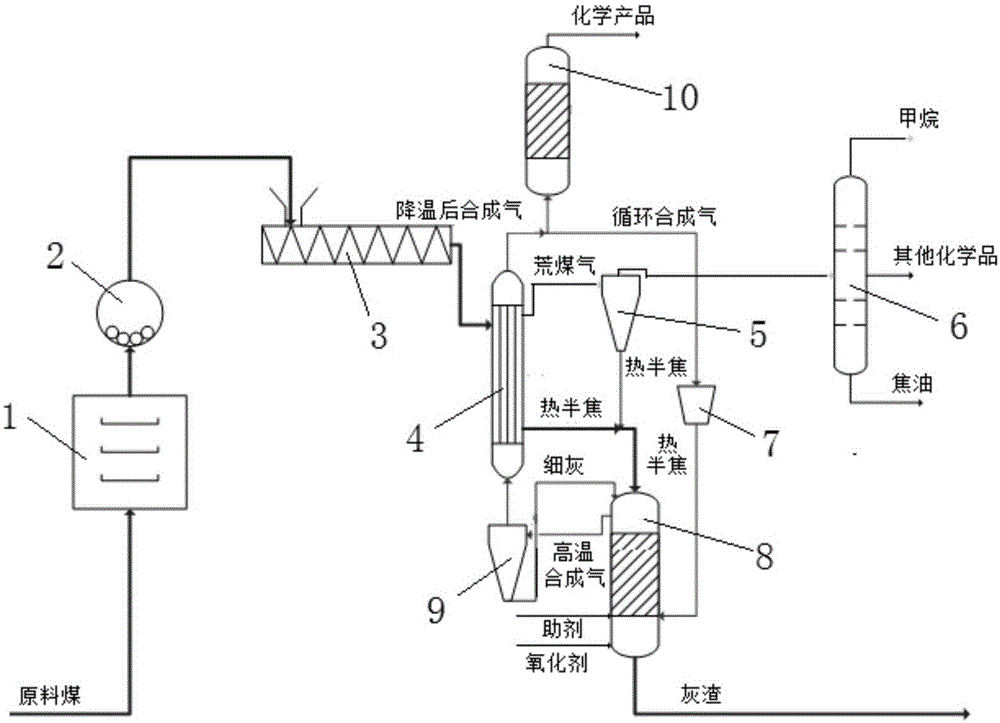

[0028] An indirect pyrolysis system, including a pulverized coal pretreatment unit, a gasification pyrolysis coupling unit, a pyrolysis product separation unit, and a synthesis gas conversion unit; the gasification pyrolysis coupling unit includes a pyrolysis furnace 4 and a high-temperature synthesis gas compressor 7 , gasifier 8 and high-temperature syngas dedusting device 9; pulverized coal pretreatment unit includes lump coal drying device 1, coal grinding device 2 and pulverized coal mechanical feeding device 3; pyrolysis product separation unit includes pyrolysis gas dedusting device 5 and pyrolysis product separation device 6; the synthesis gas conversion unit includes a synthesis gas conversion device 10; sequentially connected lump coal drying device 1, coal grinding device 2, pulverized coal mechanical feeding device 3, pyrolysis furnace 4, pyrolysis gas dedusting The device 5 and the pyrolysis product separation device 6; the pyrolysis furnace 4 is also sequentially ...

Embodiment 2

[0038] A pyrolysis method of an indirect pyrolysis system. First, the raw coal is dried through a lump coal drying device 1, and then the lump coal is pulverized into pulverized coal through a coal grinding device 2, and then fed into pyrolysis through a pulverized coal mechanical feeding device 3 Furnace 4; in the pyrolysis furnace 4, the pulverized coal on the shell side and the high-temperature syngas from the gasification furnace 8 on the tube side are exchanged for heat and pyrolysis reaction occurs to generate pyrolyzed coal gas and semi-coke substances; then, the produced The pyrolysis gas passes through the pyrolysis gas dedusting device 5 for gas-solid separation, so that the separated fine semi-coke is transported into the gasifier 8; the purified pyrolysis gas enters the pyrolysis product separation device 6 for separation to obtain pyrolysis products; The pyrolyzed semi-coke material is input into the gasifier 8; part of the syngas that has undergone heat exchange a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com