Preparation and application method for 7-ACA immobilized enzyme LK118

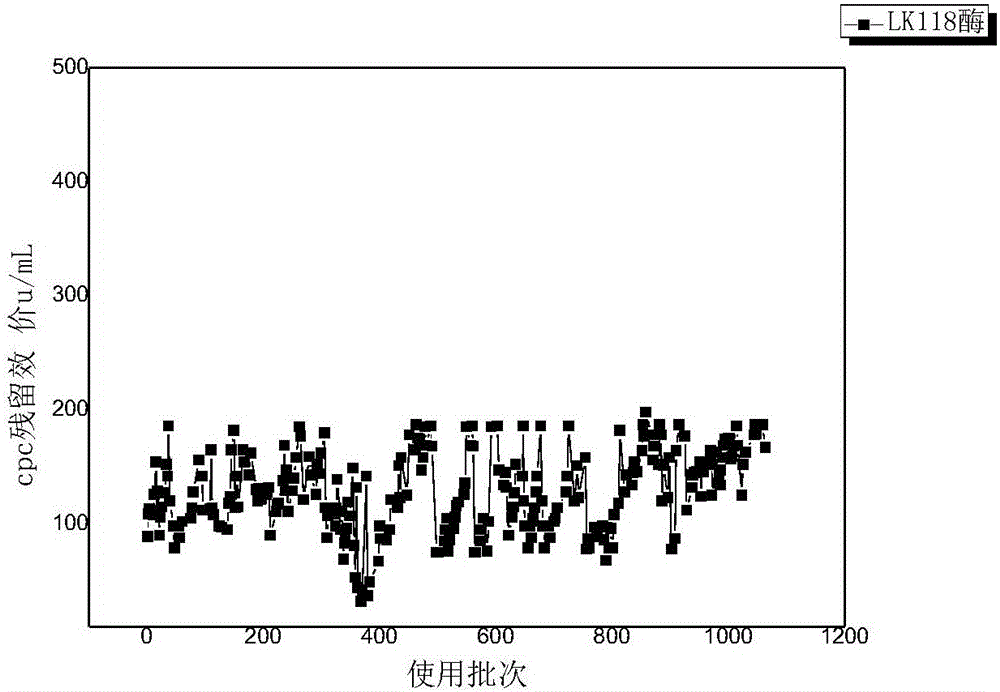

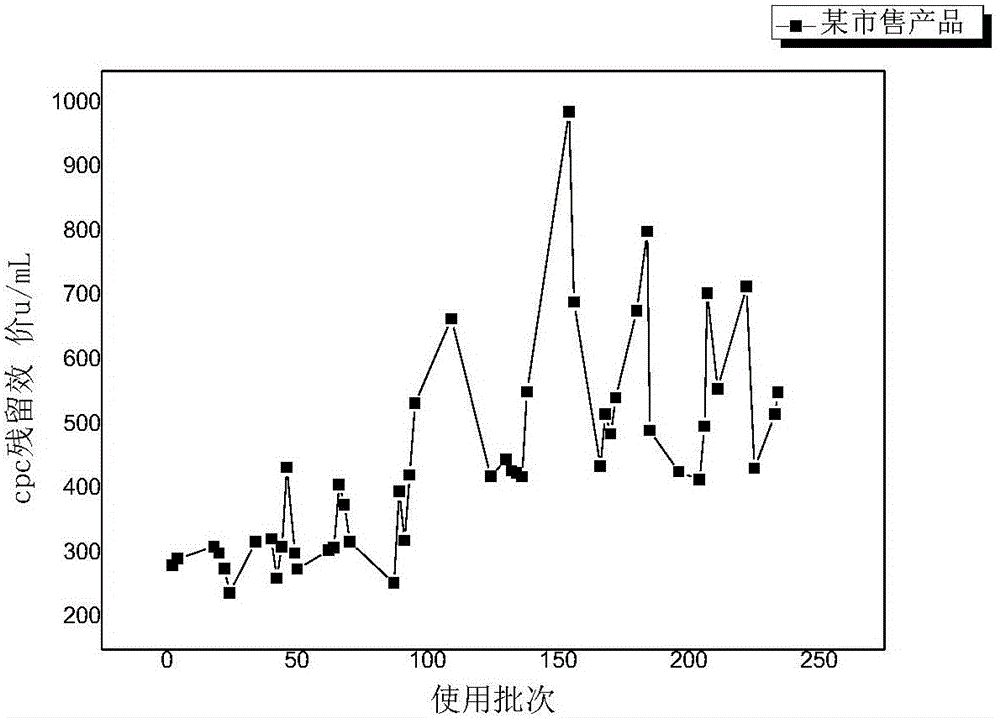

A 7-ACA, immobilized enzyme technology, applied in the direction of immobilization on/in organic carrier, transferase, chemical industry, etc., can solve the problems of high CPC residue, short service life of enzyme, low conversion rate, etc. Good carrier strength, excellent product performance, and the effect of improving the conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

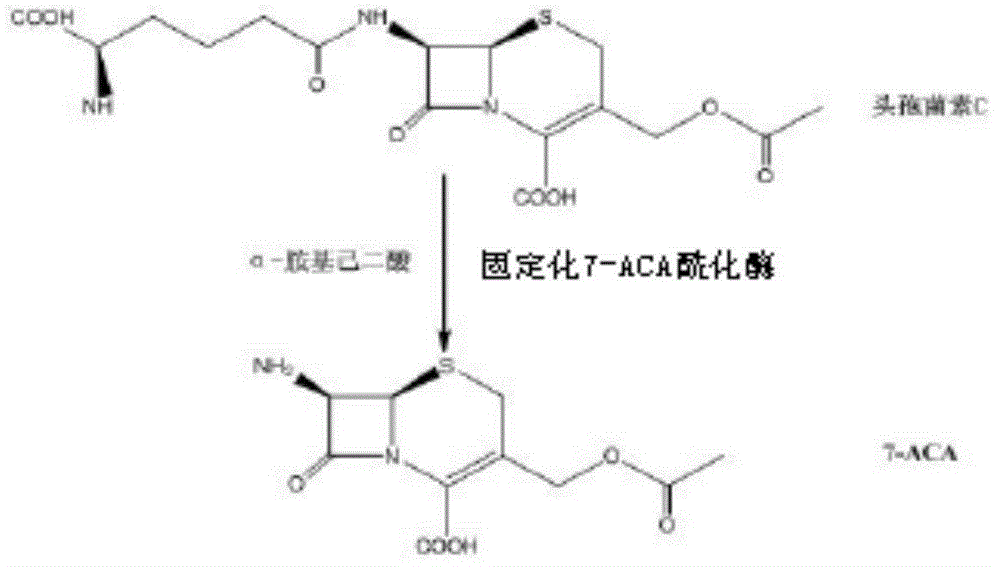

[0047] In the enzyme cleavage reactor, add 5000u (enzyme activity 100u / g, 50g) of 7-ACA-immobilized enzyme LK118 to 500mL of CPC concentrate (titer 30000u / mL), and start stirring. Add ammonia water with a mass fraction of 5%, keep the reaction pH at 8.2-8.4, control the reaction temperature at 10° C., and react for 60 minutes. After the reaction, the obtained product passes through a sieve to separate the product and 7-ACA immobilized enzyme LK118. The temperature of the reaction product is lowered to 5-10°C, the pH value is adjusted to 5.2 with 5-6 mol / L hydrochloric acid solution, the crystal is grown, washed and dried to obtain the product 7-ACA.

Embodiment 2

[0049]In the enzyme cleavage reactor, add 3500u (enzyme activity 80u / g, 43.75g) of 7-ACA-immobilized enzyme LK118 to 500mL of CPC concentrate (titer 28000u / mL), and start stirring. Add ammonia water with a mass fraction of 2%, keep the reaction pH at 8.2-8.4, control the reaction temperature at 12-13° C., and react for 65 minutes. After the reaction, the obtained product passes through a sieve to separate the product and 7-ACA immobilized enzyme LK118. The temperature of the reaction product was lowered to 8°C, the pH value was adjusted to 5.2 with 5.5 mol / L hydrochloric acid solution, the crystal was grown, washed and dried to obtain the product 7-ACA.

Embodiment 3

[0051] In the enzyme cleavage reactor, add 5000u (enzyme activity 150u / g, 33.33g) of 7-ACA-immobilized enzyme LK118 to 500mL of CPC concentrate (titer 38000u / mL), and start stirring. Add ammonia water with a mass fraction of 6%, keep the reaction pH at 8.2-8.4, control the reaction temperature at 13-14° C., and react for 80 minutes. After the reaction, the obtained product passes through a sieve to separate the product and 7-ACA immobilized enzyme LK118. The temperature of the reaction product is lowered to 5-10°C, the pH value is adjusted to 5.2 with 5-6 mol / L hydrochloric acid solution, the crystal is grown, washed and dried to obtain the product 7-ACA.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com