A kind of coated paper and its preparation method

A technology of coated paper and coating layer, which is applied in the field of papermaking, to achieve the effect of uniform ink absorption, not easy to shed, and good printing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

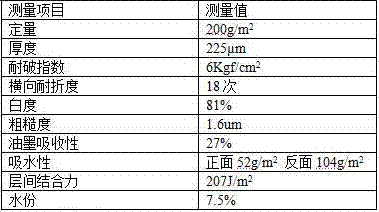

Embodiment 1

[0069] A kind of coated paper, comprises surface layer coating layer, precoating layer, surface adhesive layer, surface paper layer, core paper layer, bottom paper layer and bottom surface adhesive layer, the lower surface of described surface layer coating layer and described surface The upper surface of the adhesive layer is bonded, the pre-coating layer is arranged between the surface coating layer and the surface adhesive layer, the lower surface of the surface adhesive layer is bonded to the upper surface of the core paper layer, and the surface The paper layer is arranged between the surface rubber layer and the core paper layer, the lower surface of the core paper layer is bonded to the upper surface of the bottom surface rubber layer, and the bottom paper layer is arranged between the core paper layer and the bottom surface Between the adhesive layers, the pulp raw material of the surface paper layer includes mixed office waste paper, and the pulp raw materials of the c...

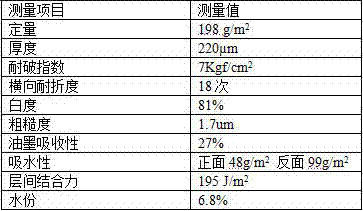

Embodiment 2

[0114] The difference between this embodiment and embodiment 1 is:

[0115] The mixed office waste paper is a mixture of American waste 37# and Japanese waste 3# in a mass ratio of 3.5:1.5; the European waste paper is a mixture of European waste 4# and European waste A2 in a mass ratio of 1:1 .

[0116] Both the raw material of the surface adhesive layer and the sizing material of the bottom adhesive layer include the following components in parts by weight: 90 parts of tapioca starch, 15 parts of surface sizing agent, 0.02 part of active amylase, and 16 parts of aluminum sulfate.

[0117] The surface sizing agent is polyacrylamide, and the active amylase is alpha amylase.

[0118] The coating of the pre-coating layer includes the following components by weight: 60 parts of calcium carbonate, 10 parts of styrene-butadiene latex, 5 parts of calcined kaolin, 0.3 parts of wet strength agent, 0.02 parts of pigment, 0.2 parts of pre-coating dispersant, 0.1 part of fungicide, 0.3 ...

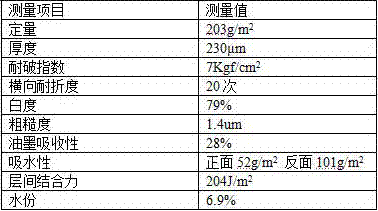

Embodiment 3

[0135] The difference between this embodiment and embodiment 1 is:

[0136]The mixed office waste paper is a mixture of American waste 37# and Japanese waste 3# in a mass ratio of 4:2; the European waste paper is a mixture of European waste 4# and European waste A2 in a mass ratio of 2:1 .

[0137] Both the raw material of the surface adhesive layer and the adhesive material of the bottom adhesive layer include the following components in parts by weight: 100 parts of tapioca starch, 20 parts of surface sizing agent, 0.04 parts of active amylase, and 18 parts of aluminum sulfate.

[0138] The surface sizing agent is polyvinyl alcohol, and the active amylase is alpha amylase.

[0139] The coating of the pre-coating layer includes the following components by weight: 75 parts of calcium carbonate, 12 parts of styrene-butadiene latex, 7 parts of calcined kaolin, 0.5 parts of wet strength agent, 0.03 parts of pigment, 0.3 parts of pre-coating paint dispersant, 0.2 parts of fungic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com