Preparation method for bandpass optical filters with central wavelengths thereof gradually varied

A band-pass filter and center wavelength technology, applied in the direction of optical filters, can solve problems such as low production efficiency and yield, restrict development and application, and decline in yield, so as to improve production efficiency and reduce etching times , the effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

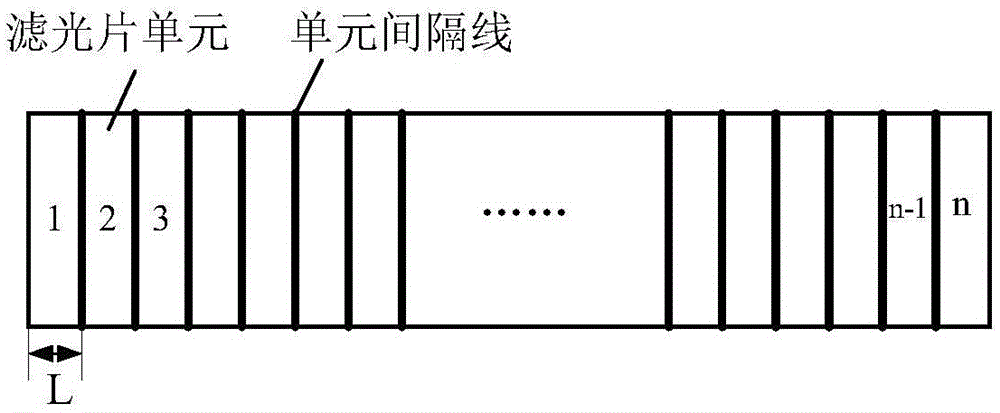

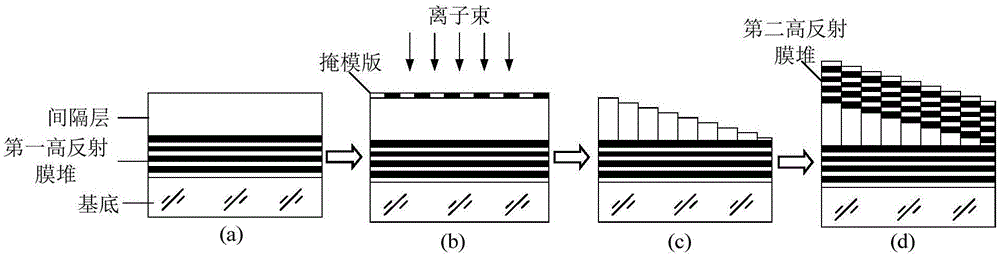

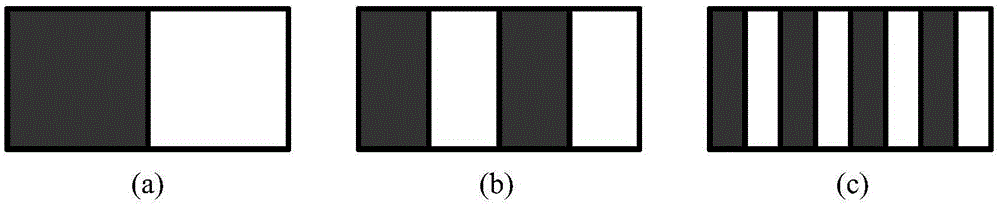

[0043] Example 1: Preparation of four filters with gradually changing central wavelengths

[0044] On the K9 glass substrate with a length of 10mm, a width of 10mm, and a thickness of 2mm, four filter filters with a unit filter width of 2.5mm and center wavelengths of 500nm, 540nm, 580nm and 620nm were prepared. Among them, the film structure corresponding to the narrow bandpass filter with the longest central wavelength is S / (HL) P 4.8H(LH) P / A, where H stands for SiN with high refractive index x Thin film, L stands for SiO with low refractive index x or SiO x f y The thin film has an optical thickness of 1000 Å, and the value range of p is generally between 5 and 10. The preparation process is to first deposit the structure on the substrate as S / (HL) P / A high reflective film stack 1, after depositing the high reflective film stack 1, continue to deposit SiN with a high refractive index with an optical thickness of 1.2 x thin film as a spacer layer, this completes as...

Embodiment 2

[0045] Embodiment 2: Preparation of eight optical filters with central wavelength gradient

[0046] On the K9 glass substrate with a length of 20mm, a width of 10mm, and a thickness of 2mm, the unit filter width is 2.5mm, and the center wavelengths are 500nm, 520nm, 540nm, 560nm, 580nm, 600nm, 620nm and 640nm. Eight wavelength gradients filter. Among them, the film structure corresponding to the narrow bandpass filter with the longest central wavelength is S / (HL) P 4.8H(LH) P / A, where H stands for SiN with high refractive index x Thin film, L stands for SiO with low refractive index x or SiO x f y The thin film has an optical thickness of 1000 Å, and the value range of p is generally between 5 and 10. The preparation process is to first deposit the structure on the substrate as S / (HL) P / A high reflective film stack 1, after depositing the high reflective film stack 1, continue to deposit SiN with a high refractive index with an optical thickness of x thin film as a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com