Etching method of ultra-high-pressure energy storage material

An energy storage material and ultra-high voltage technology, applied in the direction of electrolytic capacitors, capacitors, electrical components, etc., can solve the problems of small corrosion foil holes, easy to block specific volume, etc., achieve fast boost time, overcome small holes, process steps and The effect of parametric science

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

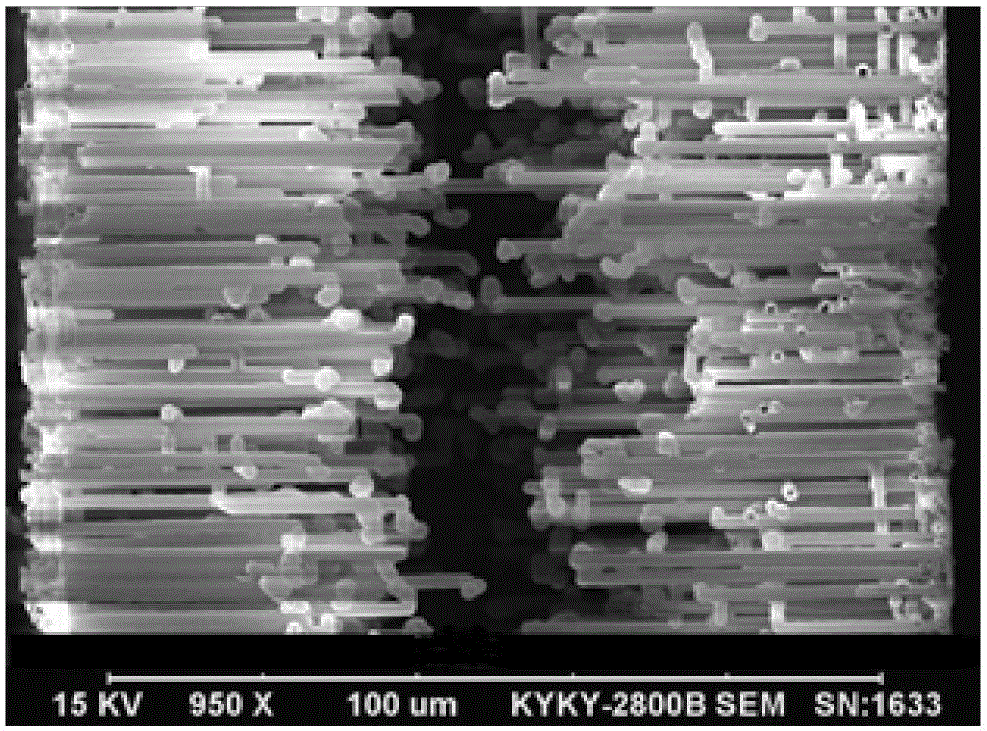

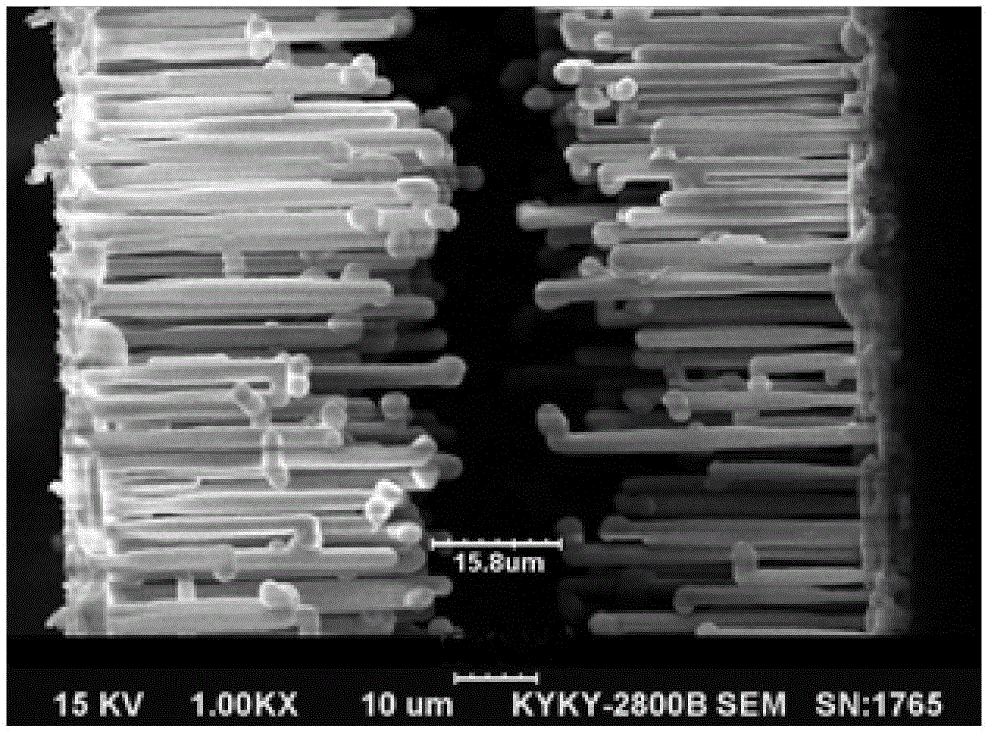

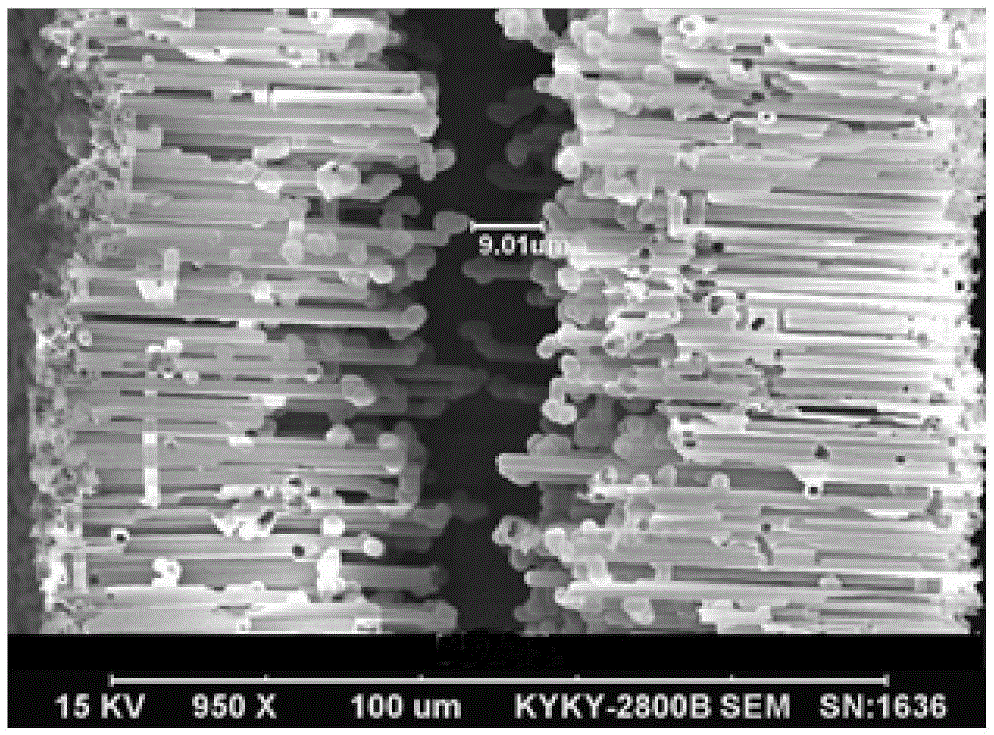

Image

Examples

Embodiment 1

[0040] 1. Preparation of raw material aluminum foil: select the aluminum foil prepared by vacuum annealing at 550°C for 1 hour as the raw material, the cubic texture is ≧96%, and the thickness is 116 μm; the chemical composition of the raw material aluminum foil is shown in Table 1.

[0041] The chemical composition of table 1 raw material aluminum foil (mass fraction, %)

[0042]

[0043] Two, adopt the method of the present invention to prepare corroded foil, comprise the following steps:

[0044] (1) Pretreatment: first soak the raw material aluminum foil in 0.8mol / L sodium hydroxide solution for 60s, control the treatment temperature at 50°C; then soak the aluminum foil in a mixed solution containing 3wt% sulfuric acid and 5wt% phosphoric acid for 120s , control the treatment temperature at 60°C; finally use deionized water to wash the aluminum foil at room temperature for 2 minutes;

[0045] (2) One-level direct-current electrochemical corrosion: place the aluminum fo...

Embodiment 2

[0053] 1. Preparation of raw material aluminum foil: select the aluminum foil prepared by vacuum annealing at 530°C for 1.5h as the raw material, the cubic texture is ≧95%, and the thickness is 110 μm; the chemical composition of the raw material aluminum foil is shown in Table 2.

[0054] The chemical composition of table 2 raw material aluminum foil (mass fraction, %)

[0055]

[0056] Two, adopt the method of the present invention to prepare corroded foil, comprise the following steps:

[0057] (1) Pretreatment: first soak the raw material aluminum foil in 1mol / L sodium hydroxide solution for 50s, control the treatment temperature to 455°C; then soak the aluminum foil in a mixed solution containing 5wt% sulfuric acid and 3wt% phosphoric acid for 150s, Control the treatment temperature at 50°C; finally use deionized water to wash the aluminum foil at room temperature for 3 minutes;

[0058] (2) First-level direct current electrochemical corrosion: place the aluminum foil...

Embodiment 3

[0066] 1. Preparation of raw material aluminum foil: select the aluminum foil prepared by vacuum annealing at 580°C for 0.5h as the raw material, with a cubic texture ≥ 95% and a thickness of 120 μm; the chemical composition of the raw material aluminum foil is shown in Table 3.

[0067] The chemical composition of table 3 raw material aluminum foil (mass fraction, %)

[0068]

[0069] Two, adopt the method of the present invention to prepare corroded foil, comprise the following steps:

[0070] (1) Pretreatment: first soak the raw material aluminum foil in 0.5mol / L sodium hydroxide solution for 80s, control the treatment temperature at 60°C; then soak the aluminum foil in a mixed solution containing 2wt% sulfuric acid and 8wt% phosphoric acid for 60s , control the treatment temperature to 70°C; finally use deionized water to wash the aluminum foil at room temperature for 2 minutes;

[0071] (2) One-level direct-current electrochemical corrosion: place the aluminum foil tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com