Chip-on-board (COB) light source of flip chip mining lamp

A high bay lamp and flip-chip technology, applied in the field of lighting, can solve the problems that the light source cannot withstand high-frequency vibration for a long time, poor contact, light source disconnection and dead lights, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

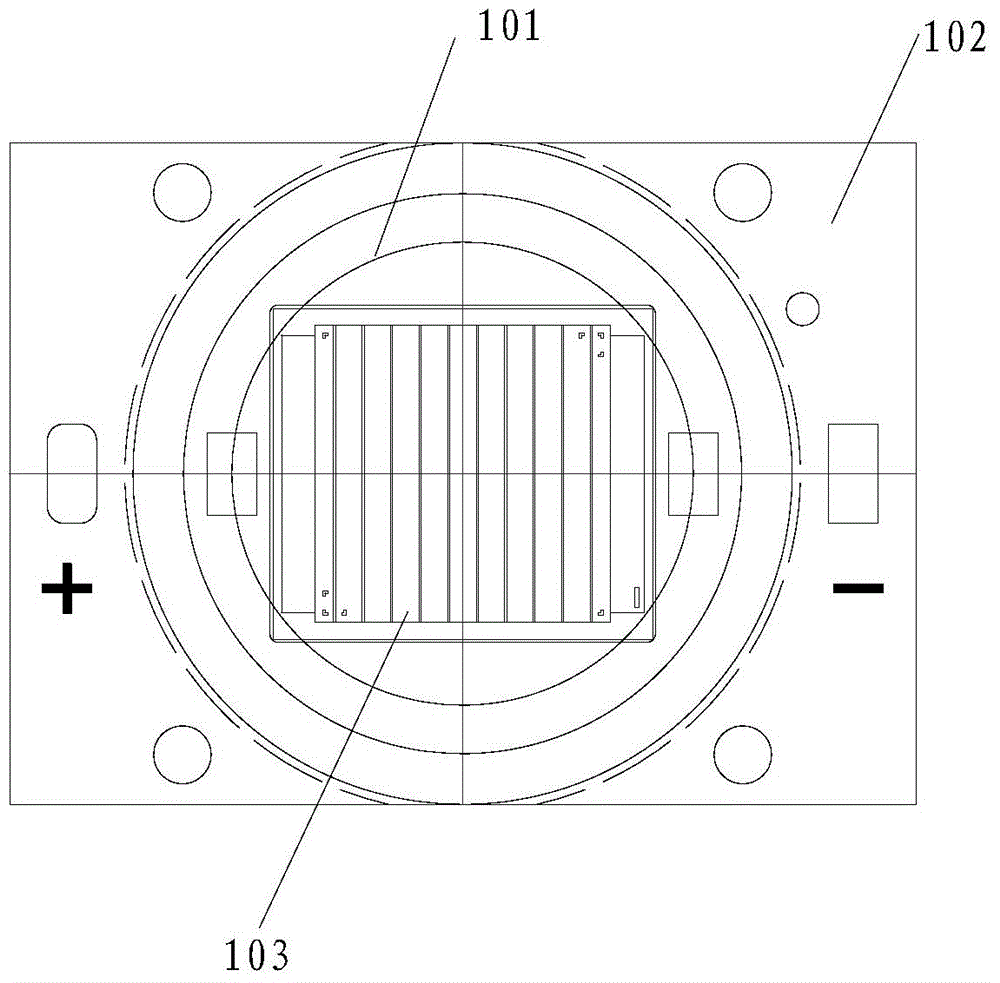

[0029] refer to figure 1 , figure 1 It is a structural schematic diagram of a COB light source for a flip-chip high bay lamp provided by an embodiment of the present invention.

[0030] exist figure 1 Among them, the COB light source of the flip-chip industrial and mining lamp includes a heat-dissipating copper substrate 102, an aluminum nitride ceramic bracket 103, and an optical glass lens 101. The aluminum oxide ceramic support 103 includes a support body made of aluminum nitride ceramics, a plurality of crystal-bonding areas are evenly arranged on one side of the support support body, and the optical glass lens 101 is pasted on the heat dissipation copper substrate 102. directly above the die package block.

[0031] An embodiment of the present invention provides a COB light source for a flip-chip high bay lamp. The COB light source for a flip-chip high bay lamp includes a heat-dissipating copper substrate, an aluminum nitride ceramic bracket, and an optical glass lens....

Embodiment 2

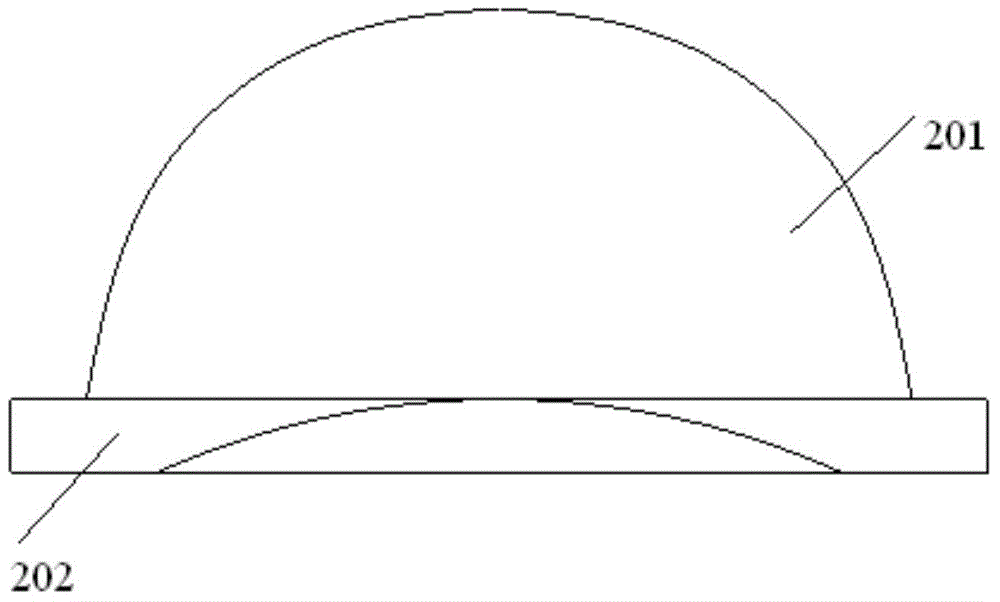

[0033] refer to figure 2 , figure 2 It is a structural schematic diagram of an optical glass lens provided by an embodiment of the present invention.

[0034] exist figure 2 Among them, there is a circular groove in the middle of the bottom of the optical glass lens 201, and the edge of the optical glass lens 201 is frosted; the optical glass lens 201 is pasted directly above the chip packaging block on the heat dissipation copper substrate .

[0035] The refractive index of the optical glass lens is 1.474.

[0036] The acid resistance of the optical glass lens reaches grade 1, and the alkali resistance reaches grade A.

[0037] The coefficient of expansion of the optical glass lens is 3.3.

[0038] Specifically, the material of the optical glass lens has the advantages of high transparency, wear resistance, smooth surface, easy cleaning, health and hygiene; the expansion coefficient of the optical glass lens is 3.3, and the expansion coefficient of high borosilicate g...

Embodiment 3

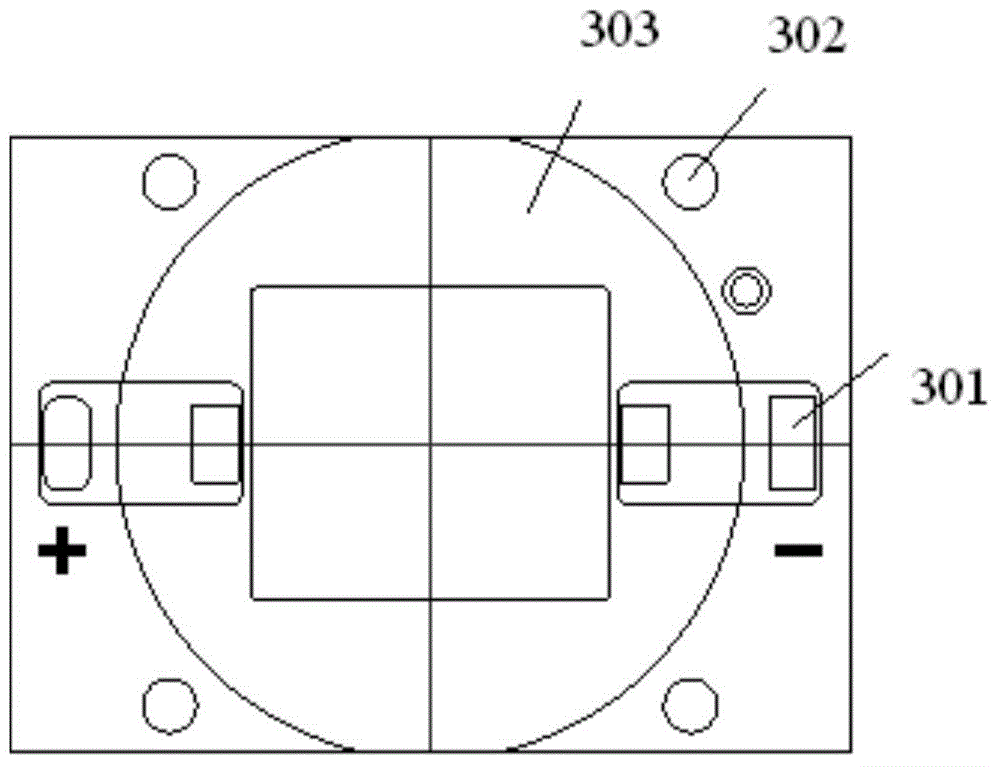

[0041] refer to image 3 , image 3 It is a schematic structural diagram of a heat dissipation copper substrate provided by an embodiment of the present invention.

[0042] exist image 3 Among them, the heat dissipation copper substrate includes a sunken platform structure 301, a through hole structure 302 and a copper foil circuit 303, and the sunken platform structure 301, the through hole structure 302 and the copper foil on the upper surface of the heat dissipation copper substrate Lines 303 and 303 are electroplated with gold.

[0043] Specifically, in image 3 Among them, the area marked by a square area such as 301 is a sunken platform structure, the area marked by a circular area such as 302 is a through-hole structure, and the area other than those marked by 301 and 302 is a copper foil circuit.

[0044] Preferably, the heat-dissipating copper substrate includes a 0.15mm deep sunken platform structure 101 and a 3.5mm through hole structure 102 .

[0045] Prefera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dimensions | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com