Zirconium-doped lithium-rich cathode material of lithium ion battery and preparation method of zirconium-doped lithium-rich cathode material

A lithium-rich cathode material, lithium-ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of mixed cations, low capacity of cathode materials, and poor rate performance, and achieve high production efficiency and reaction conditions. Easy-to-control, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

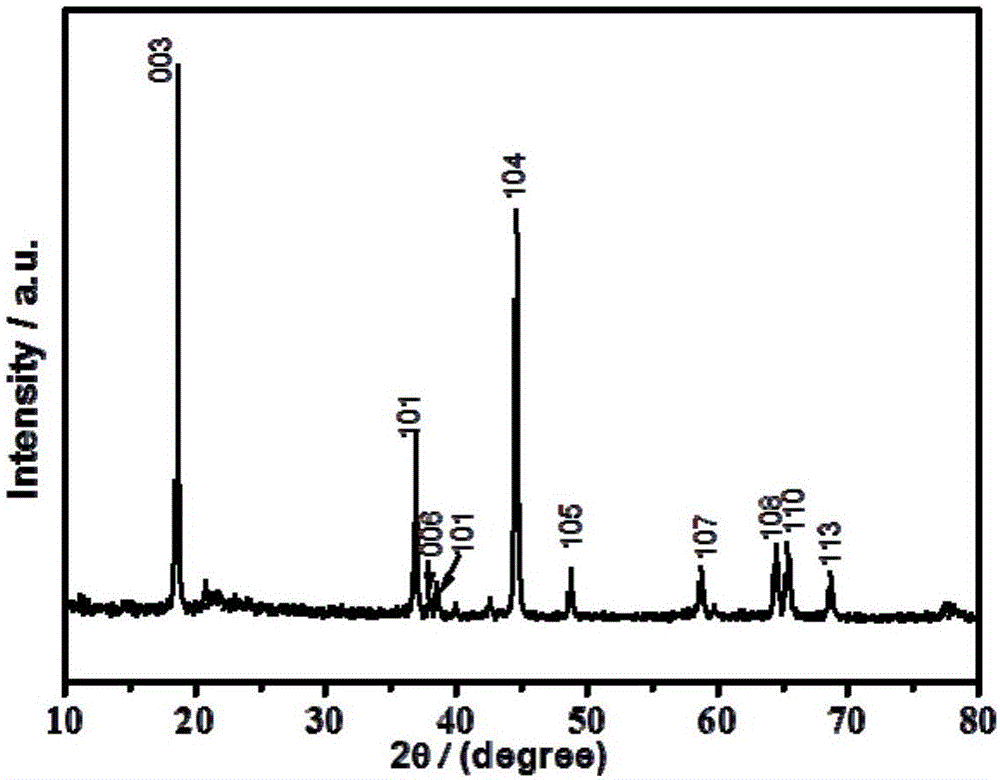

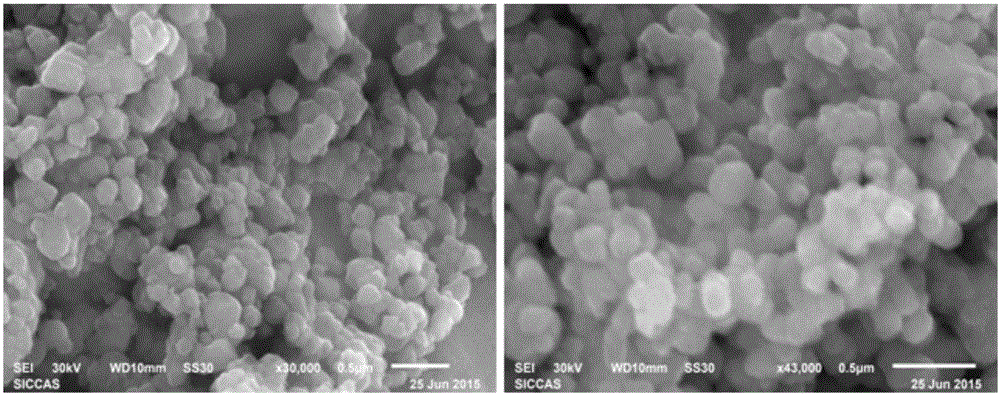

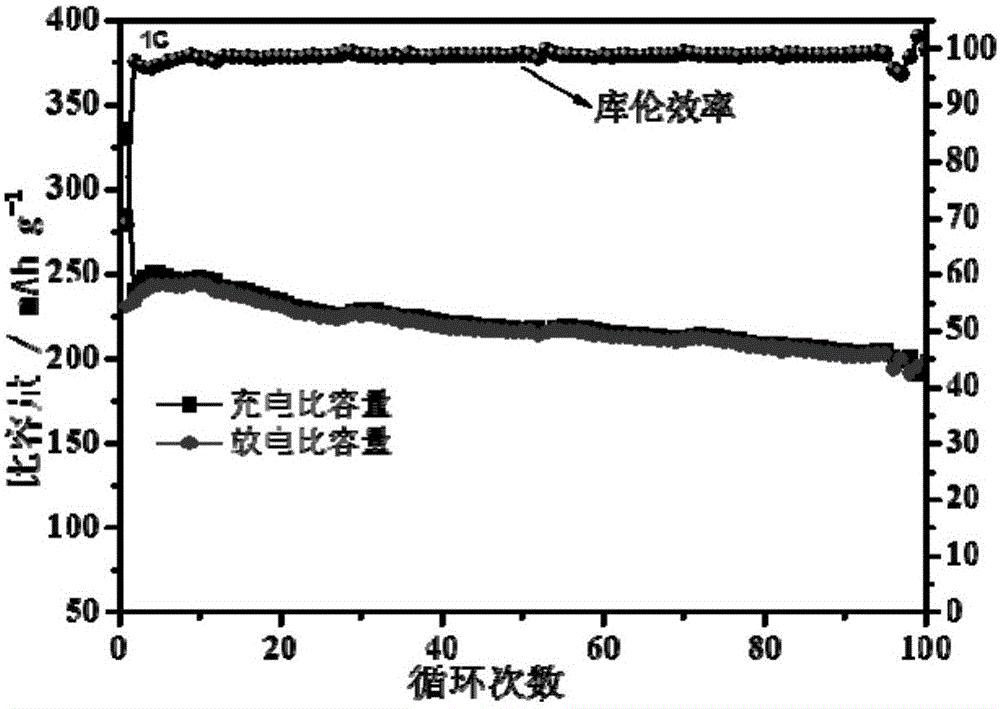

[0036] A preparation method of a Zr-doped lithium-ion battery lithium-rich positive electrode material, the Zr-doped lithium-ion battery lithium-rich positive electrode material contains Li, Ni, Co, Mn, Zr and O elements, and its molecular formula is Li 1.2 (Mn 0.54 Ni 0.13 co 0.13 ) 1-x Zr x o 2 (x=0.03).

[0037] The preparation method of the above-mentioned Zr-doped lithium-ion battery lithium-rich cathode material specifically comprises the following steps:

[0038] a. Dissolve 2.5214g oxalic acid in 20ml deionized water, sonicate for 20min, stir and dissolve to obtain solution A;

[0039] b, 0.6282g cobalt acetate, 0.6276g nickel acetate, 2.5676g manganese acetate, 0.2576g zirconium nitrate and 2.5709g lithium acetate are dissolved in 40ml deionized water, according to the total of soluble cobalt salt, nickel salt, manganese salt and lithium salt Molar weight: Deionized water is mixed at a ratio of 1mol:1L and then ultrasonicated for 20 minutes to obtain solution B...

Embodiment 2

[0056] A preparation method of a Zr-doped lithium-ion battery lithium-rich positive electrode material, the Zr-doped lithium-ion battery lithium-rich positive electrode material contains Li, Ni, Co, Mn, Zr and O elements, and its molecular formula is Li 1.2 (Mn 0.54 Ni 0.13 co 0.13 ) 1-x Zr x o 2 (x=0.01).

[0057] The above-mentioned preparation method of a Zr-doped lithium-ion battery lithium-rich positive electrode material specifically comprises the following steps:

[0058] a. Dissolve 2.5214g oxalic acid in 20ml deionized water, sonicate for 20min, stir and dissolve to obtain solution A;

[0059] b, 0.6411g cobalt acetate, 0.6405g nickel acetate, 2.6205g manganese acetate, 0.08586g zirconium nitrate and 2.5709g lithium acetate are dissolved in 40ml deionized water, according to the total of soluble cobalt salt, nickel salt, manganese salt and lithium salt Molar weight: Deionized water is mixed at a ratio of 0.5mol:1L and then ultrasonicated for 20 minutes to obtai...

Embodiment 3

[0063] A preparation method of a Zr-doped lithium-ion battery lithium-rich positive electrode material, the Zr-doped lithium-ion battery lithium-rich positive electrode material contains Li, Ni, Co, Mn, Zr and O elements, and its molecular formula is Li 1.2 (Mn 0.54 Ni 0.13 co 0.13 ) 1-x Zr x o2 (x=0.02).

[0064] The above-mentioned preparation method of a Zr-doped lithium-ion battery lithium-rich positive electrode material specifically comprises the following steps:

[0065] a. Dissolve 2.5214g oxalic acid in 20ml deionized water, sonicate for 20min, stir and dissolve to obtain solution A;

[0066] b, 0.6346g cobalt acetate, 0.6341g nickel acetate, 2.5940g manganese acetate, 0.1717g zirconium nitrate and 2.5709g lithium acetate are dissolved in 40ml deionized water, according to the total of soluble cobalt salt, nickel salt, manganese salt and lithium salt Molar weight: Deionized water is mixed at a ratio of 0.75mol:1L, and solution B is obtained under ultrasonication...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com