Powder enzyme food prepared from germinated brown rice

A germinated brown rice and enzyme technology, which is applied in the field of food processing, can solve the problems that hinder the widespread promotion of germinated brown rice, rice taste, poor taste, and difficult to accept by consumers, so as to achieve rich taste and nutrition, mellow and smooth taste, and improve nutritional functions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The preparation process of described powder ferment food comprises the following steps:

[0045] 1) Contact, mix and grind germinated brown rice and hemp seeds, and pass through a 40-60 mesh sieve to obtain powder, and stir-fry the powder above 120°C until the fragrance of grains is released, so as to obtain mixed powder I;

[0046] 2) Vacuum-dry black fungus and wolfberry at 50-60°C, mix and pulverize them, and pass through a 40-60 mesh sieve to obtain mixed powder II;

[0047] 3) Add mixed powder I, mixed powder II, soybean protein powder, oat bran, instant tea powder and arabinose into a solid fermenter, stir and mix well, perform in-situ sterilization and then cool down to 25-35°C to obtain a dry material;

[0048] 4) The honey is contacted with pure water equivalent to 15-30% of the weight of the dry material, fully dissolved and mixed, and sterile filtered to obtain a honey solution. The honey solution is added to a solid fermentation tank by spraying to mix with ...

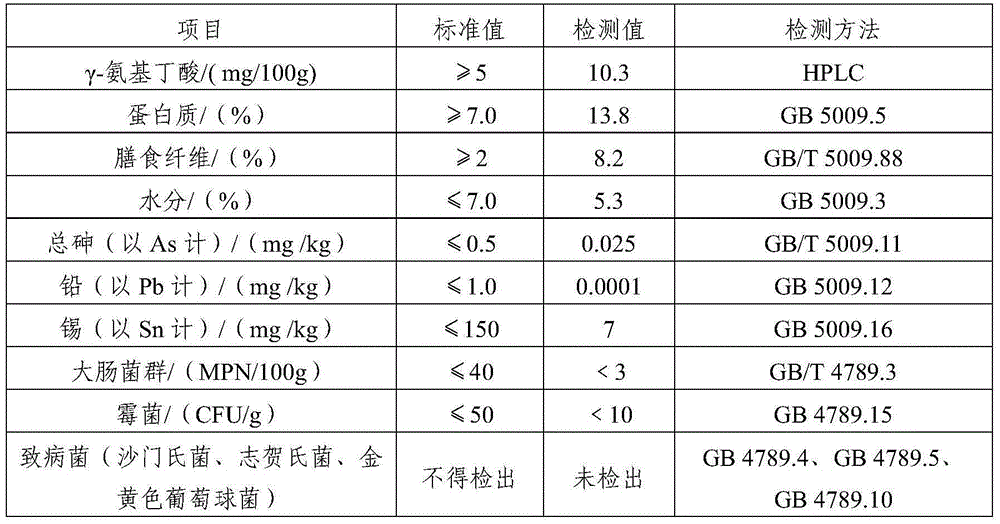

Embodiment 1

[0061] (1) Get 3000g of dried japonica rice germinated brown rice (41mg / 100g of gamma-aminobutyric acid content, 97% germ retention rate), 1800g of hemp seed, mix and pulverize, and make the material pass through a 50-mesh sieve;

[0062] (2) Stir-fry the mixed powder described in the above (1) above 120°C until the obvious grain fragrance is emitted, and the mixed powder I is prepared;

[0063] (3) Wash and remove 600g of black fungus and 700g of wolfberry, then vacuum-dry them at 50°C, mix and pulverize them, and pass the materials through a 50-mesh sieve to obtain mixed powder II;

[0064] (4) Weigh 1300g of soybean protein powder, 700g of oat bran, 150g of instant green tea powder, and 800g of L-arabinose, put them into a solid fermenter, and add mixed powder I and mixed powder II at the same time;

[0065] (5) After the materials are mixed, heat up the fermenter, sterilize the materials in place, and sterilize at 90°C for 30 minutes;

[0066] (6) After the sterilization ...

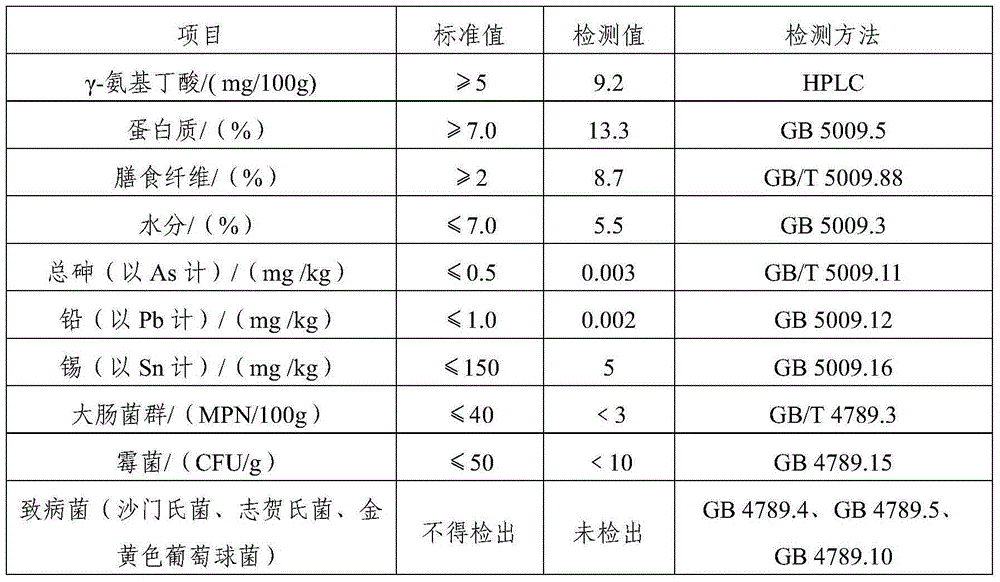

Embodiment 2

[0075] (1) Take 1000g of germinated brown rice of dry black glutinous rice (35mg / 100g of gamma-aminobutyric acid content, 95% germ retention rate), 1000g of germinated brown rice of dry japonica rice (41mg / 100g of gamma-aminobutyric acid content, 97% germ retention rate) , hemp seed 1000g, mix and pulverize, make material cross 40 mesh sieves;

[0076] (2) Stir-fry the mixed powder described in the above (1) above 120°C until the obvious grain fragrance is emitted, and the mixed powder I is prepared;

[0077] (3) Wash and remove 500g of black fungus and 500g of wolfberry, then vacuum-dry them at 55°C, mix and pulverize them, and pass the materials through a 40-mesh sieve to obtain mixed powder II;

[0078] (4) Weigh 1000g of soybean protein powder, 500g of oat bran, 50g of instant green tea powder, and 500g of arabinose, put them into a solid fermenter, and add mixed powder I and mixed powder II at the same time;

[0079] (5) After the materials are mixed, heat up the ferment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Effective viable count | aaaaa | aaaaa |

| Viable count | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com