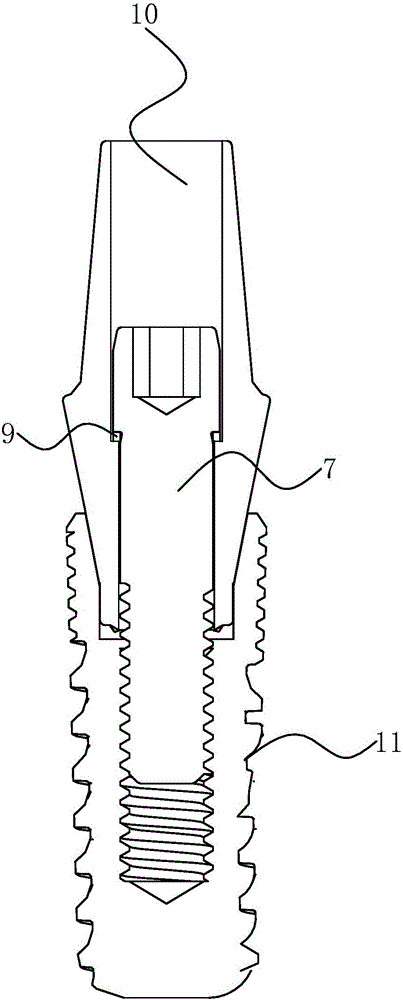

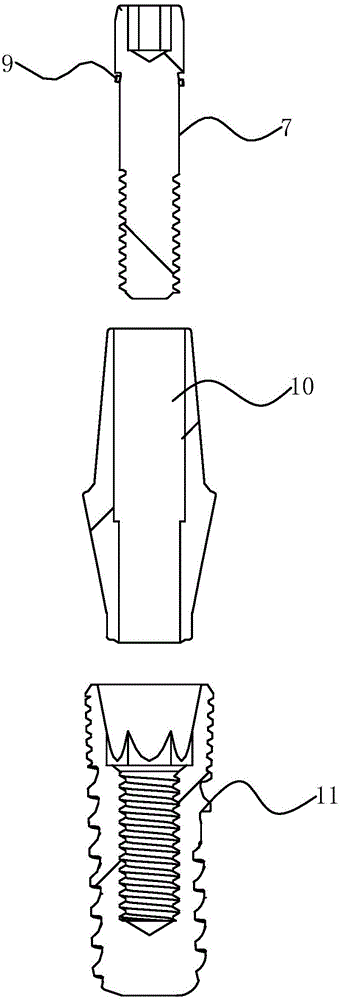

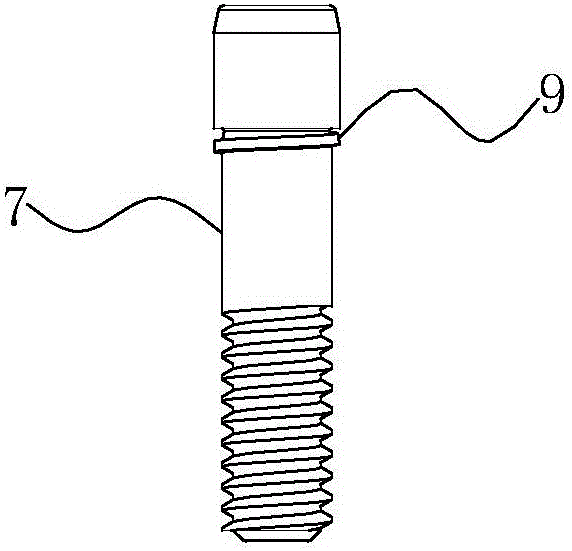

Implant tooth with high biocompatibility and stability

A biocompatible, dental implant technology, applied in the field of stomatology, can solve problems such as central bolt loosening, repair failure, and affecting dental implants, so as to improve performance and service life, prevent loosening and fracture, and prevent movement and wear. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Weigh ZrO 2 : 94.919 copies, Y 2 o 3 : 5 parts, CeO 2 : 0.01 parts, Fe 2 o 3 : 0.05 parts, Pr 6 o 11 : 0.001 parts and Er 2 o 3 : 0.02 parts, add to the mixer and mix thoroughly, and dry at 65°C for 24 hours;

[0041] Add 2 parts by weight of polyvinyl alcohol solution binder, mix well, and granulate with a 50-mesh sieve;

[0042] Then add the granulated powder into the mould, and dry press at 30Mpa under the hydraulic press, and the press is 100T;

[0043] The dry-pressed product is isostatically pressed at 160Mpa for 2 minutes, and the isostatic-pressed product is pre-sintered at 850°C for 5 hours;

[0044] Soak the pre-sintered zirconia green body in a dyeing container that keeps the height of the dyeing solution at 1 mm, and soak for 2 minutes; the weight percentage of the dyeing solution used is: polyethylene glycol 5%, erbium oxide 2%, oxide Praseodymium 1%, the balance is ultra-pure water; the liquid level of the dyeing solution is guaranteed by replen...

Embodiment 2

[0048] Weigh ZrO 2 : 93.138 copies, Y 2 o 3 : 6 parts, CeO 2 : 0.05 parts, Fe 2 o 3 : 0.01 parts, Pr 6 o 11 : 0.002 parts and Er 2 o 3 : 0.8 parts, add to the mixer and mix thoroughly and dry at 65°C for 18 hours for use;

[0049] Add 2 parts by weight of polyvinyl alcohol solution binder, mix well, and granulate with a 50-mesh sieve;

[0050] Then add the granulated powder into the mould, and dry press at 50Mpa under the hydraulic press to form;

[0051] After dry pressing, the product is isostatically pressed at 180Mpa for 2 minutes;

[0052] The product after isostatic pressing is pre-sintered at 1100°C and kept for 3 hours;

[0053] Soak the pre-sintered zirconia body in a dyeing container that keeps the height of the dyeing solution at 0.5 mm for 3 minutes; the weight percentage of the dyeing solution used is: polyethylene glycol 3%, erbium oxide 0.2%, praseodymium oxide 5%, the balance is ultrapure water;

[0054] After soaking, dry at 100°C for 3 hours; the...

Embodiment 3

[0057] Weigh ZrO 2 : 92.39 copies, Y 2 o 3 : 7 parts, CeO 2 : 0.01 parts, Fe 2 o 3 : 0.05 parts, Pr 6 o 11 : 0.05 parts and Er 2 o 3 : 0.5 parts, add to the mixer and mix thoroughly and dry at 80°C for 24 hours for use;

[0058] Add 4 parts by weight of polyvinyl alcohol solution binder, mix well, and granulate with a 50-mesh sieve;

[0059] Then add the granulated powder into the mould, and dry press at 30Mpa under the hydraulic press to form;

[0060] The product after dry pressing is isostatically pressed at 160Mpa for 2 minutes, and the product after isostatic pressing is pre-sintered at 900°C and kept for 5 hours;

[0061] Soak the pre-sintered zirconia body in a dyeing container that keeps the dyeing solution at a height of 3 mm for 1 minute; the weight percentage of the dyeing solution used is: polyethylene glycol 5%, erbium oxide 0.5%, praseodymium oxide 10 %, the balance is ultrapure water;

[0062] After soaking, dry at 130°C for 2 hours; final sinter the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com