Preparation method of immobilized tannins adsorption resin

A technology for adsorbing resin and tannin, which is applied in the field of preparation of cured tannin adsorption resin, can solve problems such as tannin limitation, and achieve the effects of low cost, strong adsorption capacity and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

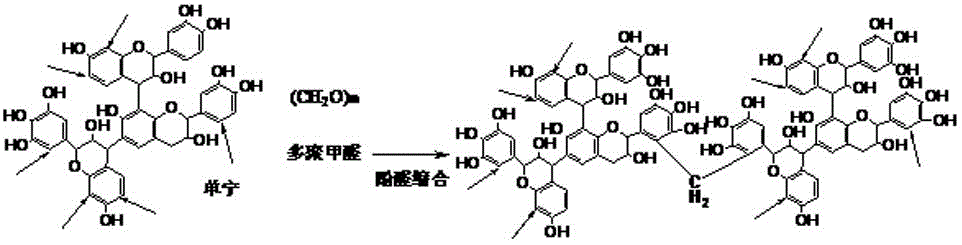

[0015] (1) Synthesis of tannin-based phenolic resin, dissolving tannin in 5% sodium hydroxide solution to prepare a 27% tannin solution, and then adding 1.5% tannin based on the quality of tannin to the tannin solution in 3 batches Paraformaldehyde was placed in a water bath at 40°C and reacted for 3.9 hours under magnetic stirring.

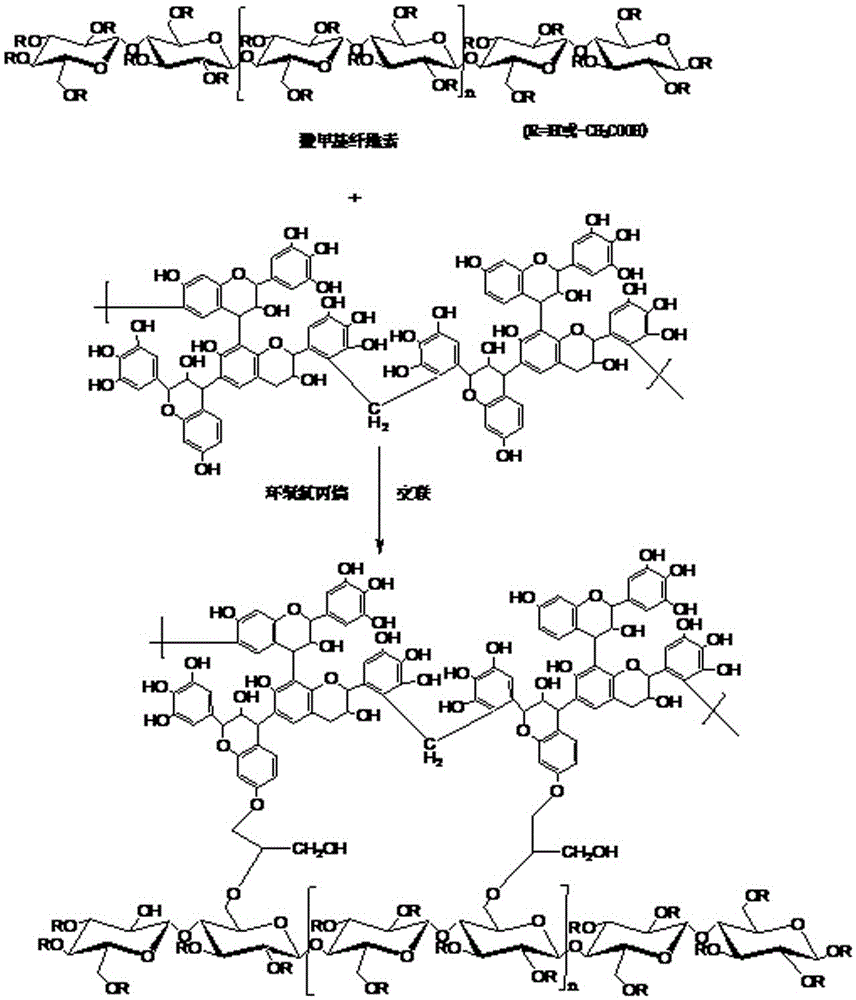

[0016] (2) Synthesis of cured tannin adsorption resin, dissolving 42% carboxymethyl cellulose based on tannin mass in 5% sodium hydroxide solution to prepare carboxymethyl cellulose solution with a concentration of 4.7%, and then (1 ) synthesized tannin-based phenolic resin solution and carboxymethylcellulose solution, then added 5.5% epichlorohydrin based on the total mass of tannin and carboxymethylcellulose, vigorously stirred for 9 minutes, and stood at 40°C After 4 hours a cured tannin adsorbent resin was obtained.

[0017] The obtained solidified tannin adsorption resin can be used after being soaked in deionized water, washed and dried. T...

Embodiment 2

[0019] (1) Synthesis of tannin-based phenolic resin, dissolving tannin in 5% sodium hydroxide solution to prepare a tannin solution with a concentration of 12%, and then adding 4.7% tannin based on tannin quality in 3 batches to the tannin solution Paraformaldehyde was placed in a water bath at 40°C and reacted for 3.2 hours under magnetic stirring.

[0020] (2) Synthesis of cured tannin adsorption resin, dissolving 188% carboxymethyl cellulose based on tannin quality in 5% sodium hydroxide solution to prepare carboxymethyl cellulose solution with a concentration of 1.4%, and then (1 ) synthesized tannin-based phenolic resin solution and carboxymethyl cellulose solution, then added 9.2% epichlorohydrin based on the total mass of tannin and carboxymethyl cellulose, vigorously stirred for 6 minutes, and stood at 40°C After 4 hours a cured tannin adsorbent resin was obtained.

[0021] The obtained solidified tannin adsorption resin can be used after being soaked in deionized wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com