Primary layer coating for manufacturing shell of precision casting and preparation method of primary layer coating

A technology for surface coatings and precision castings, applied in casting molding equipment, coatings, casting molds, etc., can solve the problem of poor compounding effect of defoaming agent or wetting agent and slurry, inability to obtain affinity and surface smoothness, Wax surface corrosion and other problems, to avoid wax corrosion, linear shrinkage stability, improve puncture resistance, and good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

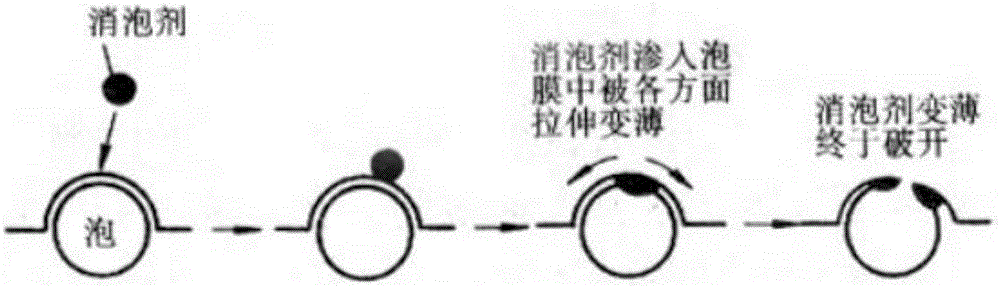

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A surface coating for shell making of precision castings, which is composed of the following raw materials by weight: 10 parts of silica sol, 40 parts of zircon powder, 0.015 parts of defoaming agent, and 0.04 part of wetting agent.

[0037] The preparation method is as follows:

[0038] The room temperature is 22-27°C. When the temperature exceeds 27°C, it will cause cracks in the shell mold, dry transition and other undesirable phenomena, and iron fins, flashes, and shell swelling will appear in the casting.

[0039] When all the surface coatings are new materials, the stirring time is ≥24h, and for some new materials, the stirring time is ≥12h;

[0040] When the transition layer paint and the back layer paint are all new materials, the stirring time is ≥10h, and the stirring time of some new materials is ≥5h;

[0041] Less than 50% new material: stirring time 4-5h;

[0042] More than 50% new material: stirring time 6-12h;

[0043] More than 75% new material: stirr...

Embodiment 2

[0061] A surface coating for shell making of precision castings is characterized in that it consists of the following raw materials in weight ratios: 10 parts of silica sol, 38 parts of zircon powder, 0.015 parts of defoaming agent, and 0.04 part of wetting agent.

[0062] The preparation method is the same as in Example 1.

[0063] The prepared product can avoid shrinkage cavity or shrinkage porosity defects, has high surface finish, excellent linear shrinkage stability and puncture resistance of the shell film of the product, and the product quality can reach the product quality standard of precision casting.

Embodiment 3

[0065] A surface coating for shell making of precision castings is characterized in that it is composed of the following raw materials in parts by weight: 10 parts of silica sol, 42 parts of zircon powder, 0.015 parts of defoaming agent, and 0.04 part of wetting agent.

[0066] The preparation method is the same as in Example 1.

[0067] The prepared product can avoid shrinkage cavity or shrinkage porosity defects, has high surface finish, excellent linear shrinkage stability and puncture resistance of the shell film of the product, and the product quality can reach the product quality standard of precision casting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com