Special cloth filter for electroosmosis sludge high-dryness dewatering equipment

A dehydration equipment and electro-osmosis technology, applied in dehydration/drying/concentrated sludge treatment, filtration and separation, chemical instruments and methods, etc., can solve problems such as difficult material removal, low service life, and non-heat-resistant filter cloth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In the present invention, the orientation words used such as "up, down, left and right" usually refer to the up, down, left and right shown in the accompanying drawings; "inside and outside" refer to the outline relative to each part itself inside and outside.

[0027] For ease of understanding, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

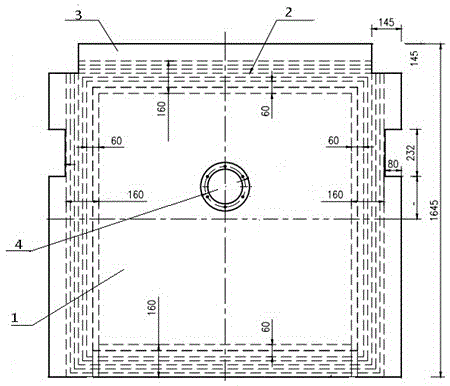

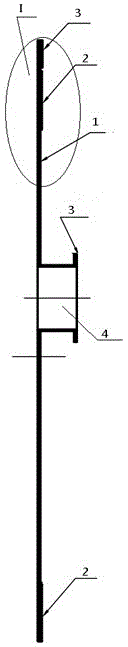

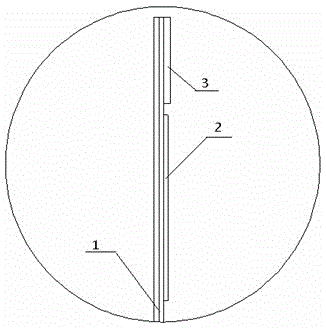

[0028] see figure 1 , figure 2 , figure 1 It is the unfolded view of the filter cloth of the present invention. The middle part mainly matches the size of the concave part of the plate frame (that is, the bottom of the filter chamber). The filter cloth 1 is composed of two layers, namely the filter cloth body and the mesh cloth , wherein the filter cloth body is on the upper surface, which is in contact with the mud cake in the filter chamber, and plays the role of filtration and heat resistance. The filter cloth is made of nylon monofilament filter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com