Lactobacillus delbrueckii decomposition accelerator, and applications thereof in saline-alkali land straw degradation soil improvement

A technology of Lactobacillus delbrueckii and straw decomposing soil improvement, which is applied in the field of saline-alkali soil improvement, can solve the problems of long decomposing time, inconspicuous soil bulk density, and high carbon-nitrogen ratio of straws, etc., so as to improve soil organic matter content and increase Soil aggregate structure and the effect of improving soil porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

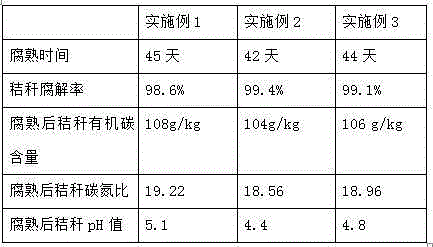

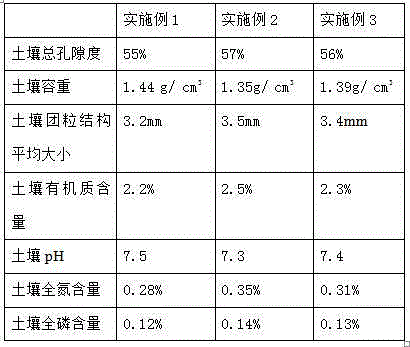

Embodiment 1

[0026] Embodiment 1 A kind of Lactobacillus delbrueckii putrefaction agent

[0027] The raw material of described decomposing agent comprises the following components by weight ratio:

[0028] 3.2 parts of compound microbial powder, 40 parts of paeonol, 20 parts of sweet-scented osmanthus pollen, 8 parts of Scenedesmus acinus;

[0029] The compound microbial powder includes Lactobacillus delbrueckii 50×10 9 CFU / g, Rhodopseudomonas palustris 60×10 9 CFU / g, Monascus 28×10 9 CFU / g, Bacillus pumilus 36×10 9 CFU / g;

[0030] Said paeonol: the water content is 12.0%, and the content of paeonol protoside is 18%~19%;

[0031] Described sweet-scented osmanthus pollen: the total sugar content is 28-32%, and the water content is 10%;

[0032] Described scenedesmus: water content is 16%.

[0033] The above percentages are all percentages by mass.

[0034] The preparation method of described decomposing agent:

[0035] Step 1, preparing composite microbial powder

[0036] a. L...

Embodiment 2

[0048] Embodiment 2 A kind of Lactobacillus delbrueckii putrefaction agent

[0049] The raw material of described decomposing agent comprises the following components by weight ratio:

[0050] 4.1 parts of compound microbial powder, 45 parts of paeonol, 23 parts of sweet-scented osmanthus pollen, 10 parts of Scenedesmus acinus;

[0051] The compound microbial powder includes Lactobacillus delbrueckii 50×10 9 CFU / g, Rhodopseudomonas palustris 60×10 9 CFU / g, Monascus 28×10 9 CFU / g, Bacillus pumilus 36×10 9 CFU / g;

[0052] Said paeonol: the water content is 12.0%, and the content of paeonol protoside is 18%~19%;

[0053] Described sweet-scented osmanthus pollen: the total sugar content is 28-32%, and the water content is 10%;

[0054] Described scenedesmus: water content is 16%.

[0055] The above percentages are all percentages by mass.

[0056] The preparation method of described decomposing agent: Same as the preparation method of the decomposing agent of embodiment ...

Embodiment 3

[0057] Embodiment 3 A kind of Lactobacillus delbrueckii putrefaction agent

[0058] The raw material of described decomposing agent comprises the following components by weight ratio:

[0059] 4.6 parts of compound microbial powder, 48 parts of paeonol, 26 parts of sweet-scented osmanthus pollen, 12 parts of Scenedesmus acinus;

[0060] The compound microbial powder includes Lactobacillus delbrueckii 50×10 9 CFU / g, Rhodopseudomonas palustris 60×10 9 CFU / g, Monascus 28×10 9 CFU / g, Bacillus pumilus 36×10 9 CFU / g;

[0061] Said paeonol: the water content is 12.0%, and the content of paeonol protoside is 18%~19%;

[0062] Described sweet-scented osmanthus pollen: the total sugar content is 28-32%, and the water content is 10%;

[0063] Described scenedesmus: water content is 16%.

[0064] The above percentages are all percentages by mass.

[0065] The preparation method of described decomposing agent: Same as the preparation method of the decomposing agent of embodimen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com