Fluorinated acrylate copolymer finishing agent and preparation method therefor

An acrylate and copolymer technology, applied in the field of textile finishing agents, can solve problems such as not easy to clean, achieve excellent decontamination effect, improve fastness, and long-lasting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

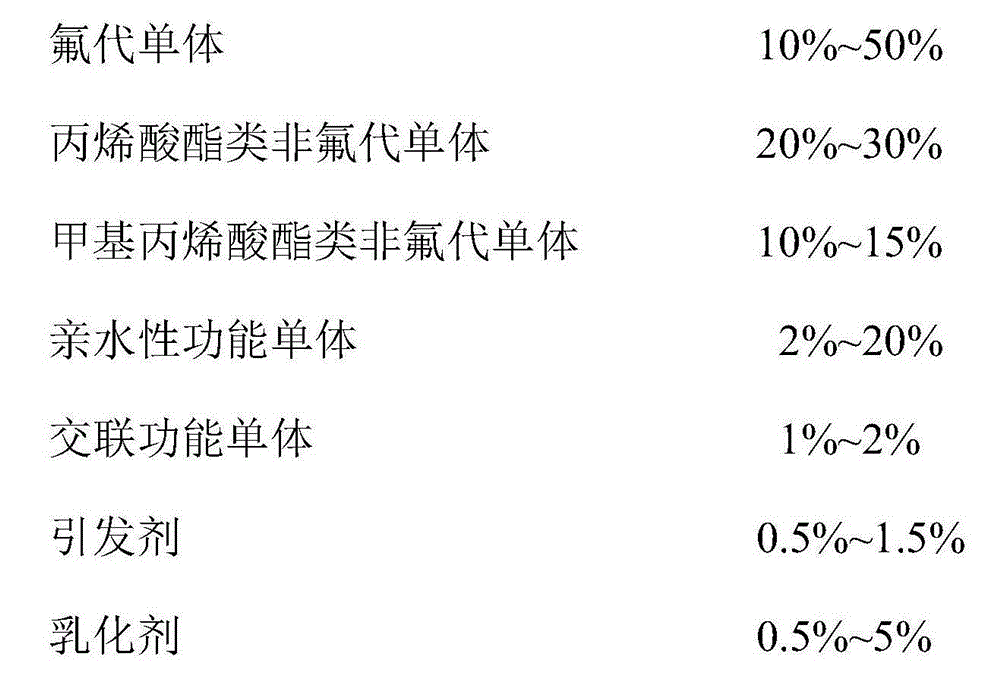

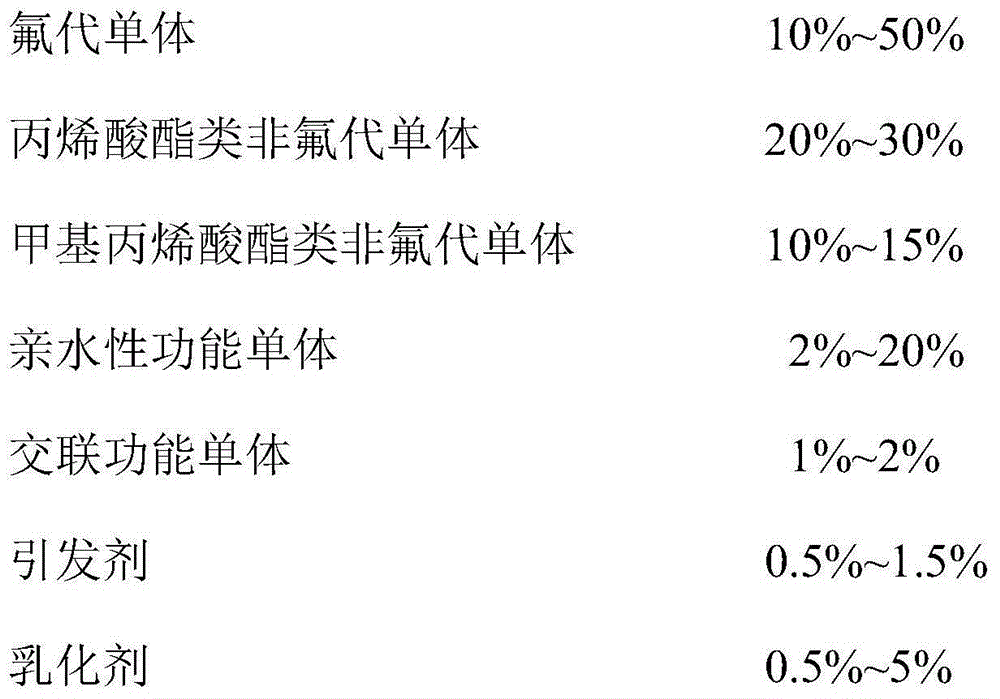

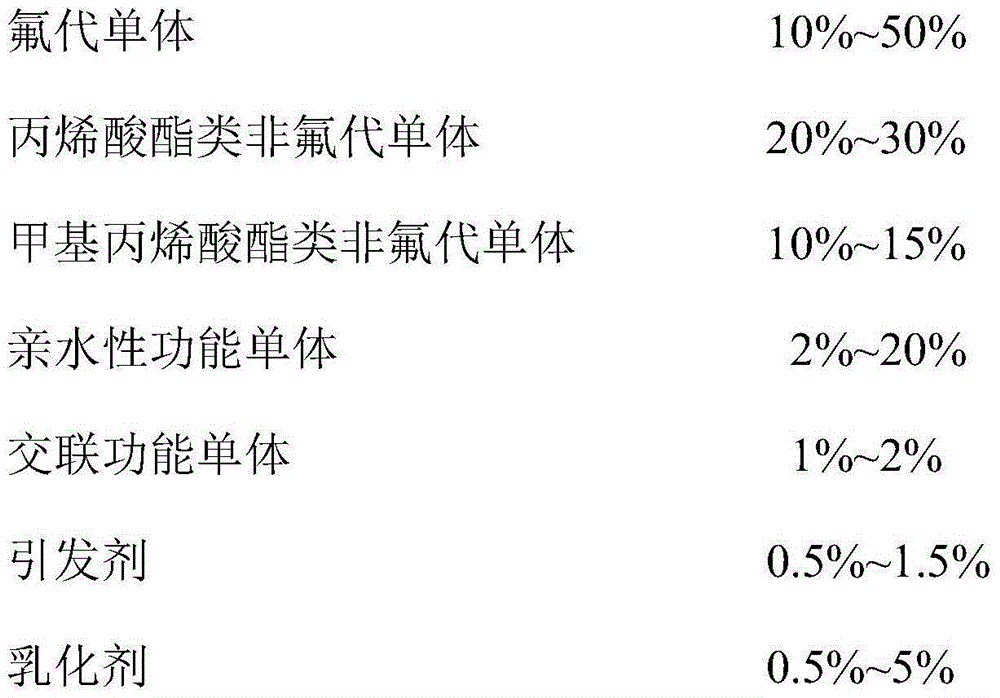

[0035] The present invention also provides a preparation method for the above-mentioned fluorine-containing acrylate copolymer finishing agent, comprising the following steps:

[0036] Step 1, weighing each raw material component according to the above mass percentage relationship.

[0037] Step 2, divide the initiator into three parts; firstly mix the water, emulsifier and the first initiator, then add fluorinated monomer, acrylate non-fluorinated monomer, methacrylate non-fluorinated Monomer, hydrophilic functional monomer and cross-linking functional monomer to obtain stock solution; emulsify the stock solution to obtain pre-emulsion; take part of the pre-emulsion as the bottom liquid, heat the bottom liquid to 75-80°C and add the second part of trigger Add the remaining pre-emulsion slowly after the bottom liquid turns blue, and keep stirring at a constant speed until the remaining pre-emulsion is added dropwise to obtain a mixed solution.

[0038] Step 3: Add the third p...

Embodiment 1

[0044] Prepare a fluorine-containing acrylate copolymer finishing agent, comprising the following steps:

[0045]Step 1: Weigh 9 g of fluorinated monomer dodecafluoroheptyl methacrylate (actyflon-G04), 6 g of non-fluorinated monomer methyl methacrylate (MMA), and 4 g of isooctyl methacrylate (EHMA) And butyl acrylate (BA) 20g, hydrophilic functional monomer acrylic acid (AA) 2g, crosslinking functional monomer N-methylolacrylamide (NMA) 1g; anionic emulsifier sodium dodecylbenzenesulfonate (SDBS) 0.3g, non-ionic emulsifier fatty alcohol polyoxyethylene ether (AEO-9) 0.3g; deionized water 45mL; initiator ammonium persulfate (APS) 0.5g to prepare 1% APS aqueous solution 15mL.

[0046] Step 2: In a three-neck flask equipped with a stirrer and a thermometer, add deionized water, SDBS and AEO-9, stir 1 mLAPS at high speed for 5 minutes to fully mix the emulsifier, then add actyflon-G04, MMA, EHMA, BA, NMA and AA, to obtain the stock solution. After pre-emulsifying the stock solut...

Embodiment 2

[0054] Prepare a fluorine-containing acrylate copolymer finishing agent, comprising the following steps:

[0055] Step 1, weigh 20 g of trifluoroethyl methacrylate as a fluorinated monomer, 15 g of ethyl methacrylate as a non-fluorinated monomer and 30 g of n-octyl acrylate, 10 g of acrylic acid as a hydrophilic functional monomer, and 10 g of acrylic acid as a crosslinking functional monomer Bulk acrylate-β-hydroxyethyl ester 1.5g; anionic emulsifier sodium dodecylbenzenesulfonate 2g, nonionic emulsifier octylphenol polyoxyethylene ether 3g; deionized water 25mL; initiator ammonium persulfate ( APS) 1g was prepared into 10mL of 1% APS aqueous solution.

[0056] Step 2: In a three-necked flask equipped with a stirrer and a thermometer, add deionized water, an emulsifier and 0.7 mL of an initiator, stir at high speed for 5 minutes to fully mix the emulsifier, and then add all the monomers to obtain a stock solution. After pre-emulsifying the stock solution for 30 minutes with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Static contact angle | aaaaa | aaaaa |

| Hydrostatic pressure | aaaaa | aaaaa |

| Static contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com