Brevibacillus parabrevis producing keratinase and application thereof

A technology of Bacillus brevis and keratinase, applied in the field of microorganisms, can solve problems such as polluting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1 Screening and identification of keratinase producing strains

[0016] (1) Medium formula

[0017] ①Preliminary screening medium: wool powder 0.5%, K 2 HPO 4 0.1%, NaCl0.05%, agar powder 2%.

[0018] ②Seed liquid culture medium

[0019] Gao's medium: soluble starch 2%, KNO 3 0.1%, NaCl0.05%, K 2 HPO 4 0.05%, MgSO 4 . 7H 2 O0.05%, FeSO 4 ·7H 2 0.001%.

[0020] LB medium: peptone 1%, yeast powder 0.5%, sodium chloride 1%.

[0021] Cha's medium: 3% sucrose, NaNO 3 0.3%, K 2 HPO 4 0.1%, MgSO 4 . 7H 2 O0.05%, KCl0.05%, FeSO 4 . 7H 2 0.001%.

[0022] ③Initial fermentation medium: MgCl 2 ·6H 2 O0.01%, K 2 HPO 4 0.03%, KH 2 PO 4 0.04%, NaCl0.05%, NH 4 Cl0.05%, wool 1%.

[0023] (2) Plate initial screening and determination of keratin activity

[0024] Soil samples were collected from rural sheep pens in Wuxi, and 1g of soil samples were added to a 50mL Erlenmeyer flask containing 10mL of normal saline and glass beads. The shaker was shake...

Embodiment 2

[0032] Example 2 Preliminary optimization of strain fermentation conditions

[0033] The fermentation medium and fermentation conditions of the strain were optimized by single factor and orthogonal experiments, and the optimal medium formula was wool 1%, soluble starch 1%, corn flour 1%, NaCl 0.15%, NH 4 Cl0.05%, K 2 HPO 4 0.03%, KH 2 PO 4 0.04%, MgCl 2 ·6H 2 O0.01%. Shaker culture conditions are as follows: initial pH value is 8.0, inoculum size is 2%, culture temperature is 40°C, rotation speed is 220r / min, liquid volume is 30mL / 250mL, fermentation period is 16h, and keratinase activity reaches 412U / mL.

Embodiment 3

[0034] Embodiment 3 enzymatic property research

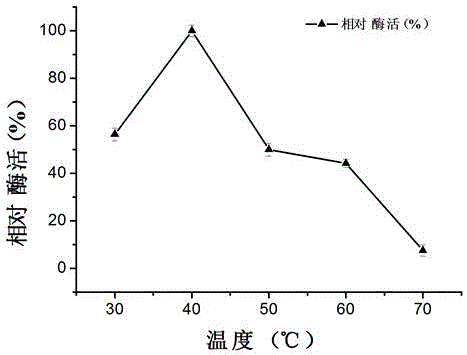

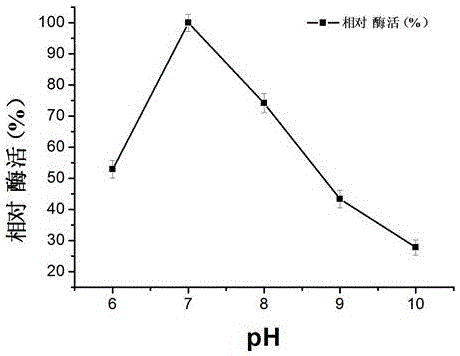

[0035] The enzymatic properties of the crude enzyme produced by the keratinase were preliminarily studied, and the effects of the action temperature (30°C-70°C) and the action pH (6.0-10.0) on the enzyme activity were studied respectively. The applicable temperature is 40°C ( figure 1 ), the optimum pH is 7.0 ( figure 2 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com