Preparation process of high-strength corrosion-resistant aluminum alloy and high-strength corrosion-resistant aluminum alloy

A corrosion-resistant aluminum alloy and a technology for the preparation process are applied in the field of aluminum alloys for automotive heat exchange system accumulators, and can solve problems such as insufficient strength of aluminum-manganese aluminum alloys.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

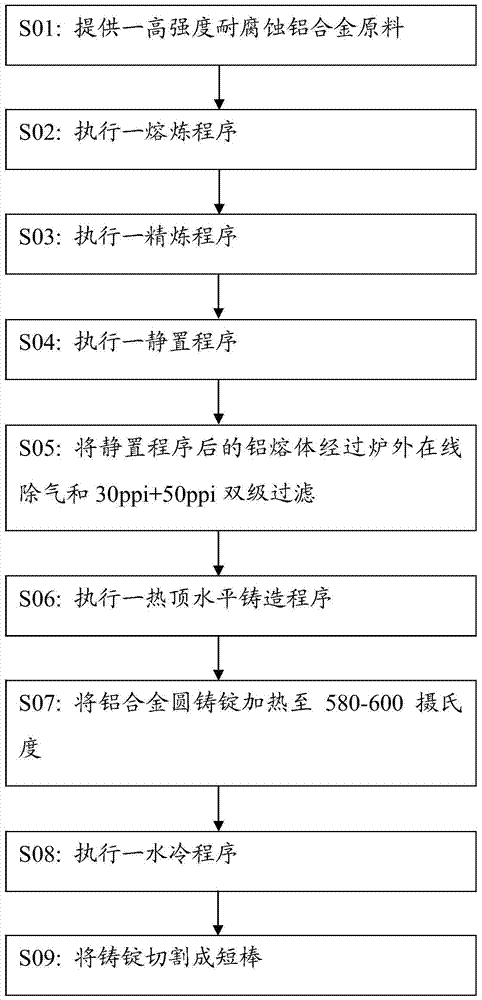

Method used

Image

Examples

Embodiment 1

[0027] The mechanical properties of Example 1 and Comparative Example are shown in the table below.

[0028] Tensile (Mpa) Yield (Mpa) Elongation (%) Embodiment one 163.3 78.6 27 comparative example 106.7 50.4 28.3

[0029] As mentioned above, the present application determines a high-strength corrosion-resistant aluminum-manganese-copper (Al-Mn-Cu) alloy and its production process, which can be applied to the liquid reservoir of the automobile heat exchange system. In this application, by increasing the content of copper element in the aluminum-manganese (Al-Mn) alloy, reducing the potential difference between the grain boundary and the grain inside the alloy, it can promote pitting corrosion to become comprehensive uniform corrosion, thereby improving the corrosion resistance of the alloy . At the same time, the existence of copper element can promote the precipitation of T phase in the form of dispersed particles in the alloy during homo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com