Method for drying jujube sheets by using heat pump

A technology of heat pump drying and red jujube slices, applied in food preparation, food science, preservation of fruits/vegetables by dehydration, etc., can solve the problems of uneven drying, long drying time, poor economy, etc. High efficiency and good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

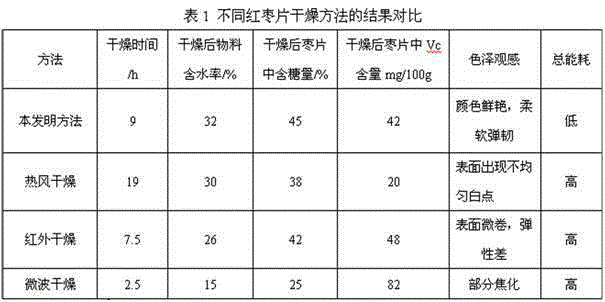

Image

Examples

Embodiment 1

[0026] A method for heat pump drying jujube slices, comprising the following steps:

[0027] (1) Clean the picked fresh jujubes with a jujube washing machine, and remove the pits from the jujubes with a pitting machine;

[0028] (2) Slice the clean jujube after pitting into thin slices with a slicer, inject water, beat the red jujube flakes to water at a mass ratio of 1:6, beat it into a powder slurry with a beater, spread it on a smooth glass sheet with a size of 450mm×250mm, and shape it , the thickness of the slurry is 2.5 ~ 3mm, after solidification, use a flaking machine to form a sheet, the thickness is 2 ~ 2.5mm;

[0029] (3) Transfer the wet jujube slices spread on smooth glass plates obtained in step (2) to a drying room, and use a heat pump for continuous drying;

[0030] (4) During step (3), the wind speed of the high-temperature and low-humidity air entering the drying chamber is 1.5m / min, the temperature is 60-65°C; the humidity is 50-55%; the wind speed of the l...

Embodiment 2

[0033] A method for heat pump drying jujube slices, comprising the following steps:

[0034] (1) Clean the picked fresh jujubes with a jujube washing machine, and remove the pits from the jujubes with a pitting machine;

[0035] (2) Slice the clean jujube after pitting into thin slices with a slicer, inject water, beat the red jujube flakes to water at a mass ratio of 1:7, beat it into a powder slurry with a beater, spread it on a smooth glass sheet with a size of 450mm×250mm, and shape it , the thickness of the slurry is 2.5 ~ 3mm, after solidification, use a flaking machine to form a sheet, the thickness is 2 ~ 2.5mm;

[0036] (3) Transfer the wet jujube slices spread on smooth glass plates obtained in step (2) to a drying room, and use a heat pump for continuous drying;

[0037] (4) During step (3), the wind speed of the high-temperature and low-humidity air entering the drying chamber is 1.5m / min, the temperature is 65-70°C; the humidity is 50-55%; the wind speed of the l...

Embodiment 3

[0040] A method for heat pump drying jujube slices, comprising the following steps:

[0041] (1) Clean the picked fresh jujubes with a jujube washing machine, and remove the pits from the jujubes with a pitting machine;

[0042] (2) Slice the clean jujube after pitting into thin slices with a slicer, inject water, beat the red jujube flakes to water at a mass ratio of 1:6, beat it into a powder slurry with a beater, spread it on a smooth glass sheet with a size of 450mm×250mm, and shape it , the thickness of the slurry is 2.5 ~ 3mm, after solidification, use a flaking machine to form a sheet, the thickness is 2 ~ 2.5mm;

[0043] (3) Transfer the wet jujube slices spread on smooth glass plates obtained in step (2) to a drying room, and use a heat pump for continuous drying;

[0044] (4) During step (3), the wind speed of the high-temperature and low-humidity air entering the drying chamber is 1.5m / min, the temperature is 70-75°C; the humidity is 50-55%; the wind speed of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com