One-time forming compartment panel for van truck and its manufacturing process

A van and manufacturing process technology, applied in the field of carriage panels, can solve the problems of low bonding strength, substandard overall strength, and short service life of the carriage panels, and achieve the effects of low cost, good performance, and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

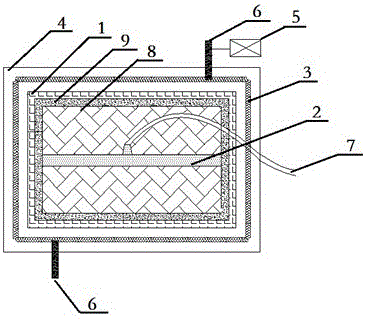

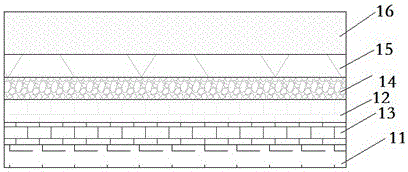

[0034] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0035] Such as image 3 As shown, a one-time forming compartment panel for a van includes a surface adhesive 11 , a first composite felt 12 , a second composite felt 13 , a PVC foam board 14 , and a flow-guiding composite felt 15 . The surface adhesive 11, the first composite felt 12, the second composite felt 13, the PVC foam board 14, and the diversion composite felt 15 are laid sequentially. The first composite felt 12 is an ordinary composite felt. The second composite felt 13 is a composite felt with flow guiding function. Further preferably, the thickness of the PVC foam board is 5-45 mm, and the present invention uses a PVC foam board with a thickness of 25 mm. Further preferably, the thickness of the compartment panel is 10-50 mm, and the present invention adopts a compartment panel with a thickness of 40 mm.

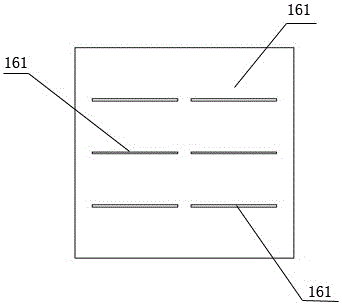

[0036] combine figur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com