A kind of preparation of rare earth permanent magnet sm 2 fe 17 n x powder process

A rare earth permanent magnet and process technology, applied in inorganic chemistry, chemical instruments and methods, iron compounds, etc., can solve problems such as alloy composition deviation, and achieve the effects of less volatilization, good reproducibility, and easy control of phase composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

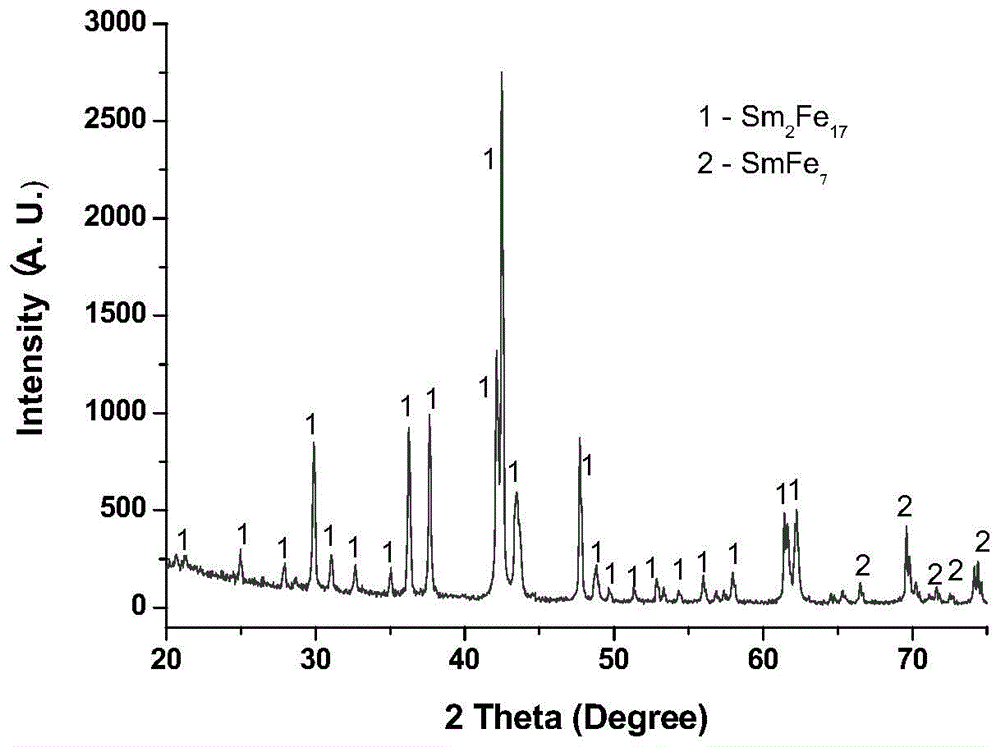

[0032] In this example, Fe powder and Sm powder were used as raw materials, and Sm was prepared by solid-liquid phase diffusion reaction method. 2 Fe 17 intermetallic compounds, and then prepared into Sm by nitriding 2 Fe 17 N x Powder. The specific process is as follows:

[0033] ①In the glove box, Fe powder (average particle size ~8 μm, purity 99.9 wt%) and Sm powder (average particle size 20 μm, purity 99.9 wt%) were weighed at a molar ratio of 2.4:17, totaling 0.5 kg.

[0034] ②Put the weighed raw material powder into a 2L sealable stainless steel ball mill jar. There are two types of stainless steel grinding balls: Φ12mm and Φ6mm, the mass ratio of ball to material is 8:1, and the volume ratio of ball to tank is ~30%. In order to prevent oxidation, add absolute ethanol to the ball mill tank to cover the ball material. Then the ball mill jar was installed on the planetary ball mill, and the ball mill was carried out for 6 hours at a speed of 125 r / m.

[0035] ③ Vac...

Embodiment 2

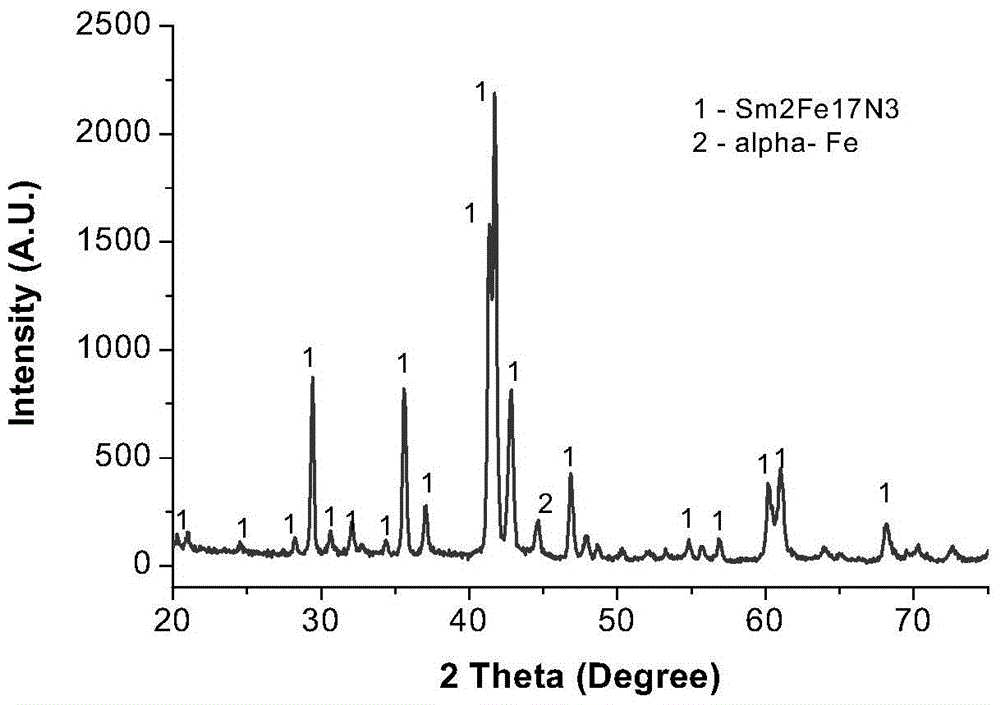

[0042] In this embodiment, FeHfCo powder (average particle size is ~10 μm, purity 99.9wt%, Hf content 10wt%, Co content 8wt%) and Sm powder (average particle size is 20 μm, purity 99.9wt%) are selected as raw material powder; wherein, " The molar ratio of "Sm and Hf" to "Fe and Co" is 2.3:17. All the other are prepared into Sm by the same processing step of embodiment 1 2 Fe 17 N x (i.e. (Sm,Hf) 2 (Fe,Co) 17 ) powder.

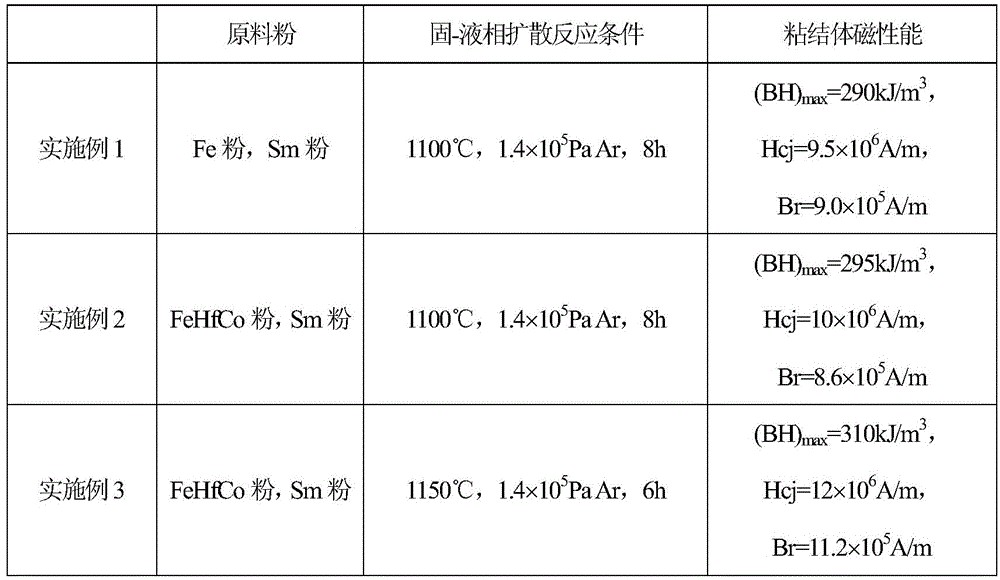

[0043] In this embodiment Sm 2 Fe 17 N x Among them, x=2.876. The obtained magnetic powder is prepared into a bonded body, and the magnetic properties are measured as follows: maximum energy product (BH) max =295kJ / m 3 , Coercivity Hcj=10×10 6 A / m, remanence Br=8.6×10 5 A / m.

Embodiment 3

[0045] In this embodiment, FeHfCo powder (average particle size is ~10 μm, purity 99.9wt%, Hf content 10wt%, Co content 8wt%) and Sm powder (average particle size is 20 μm, purity 99.9wt%) are selected as raw material powder; wherein, " The molar ratio of "Sm and Hf" to "Fe and Co" is 2.3:17. The solid-liquid phase diffusion reaction conditions are: 1150°C, 1.4×10 5 PaAr, keep warm for 6h. All the other are prepared into Sm by the same process step of embodiment 2 2 Fe 17 N x (i.e. (Sm,Hf) 2 (Fe,Co) 17 ) powder.

[0046] In this embodiment Sm 2 Fe 17 N x Among them, x=2.934. Prepare the obtained magnetic powder into a bonded body, and measure the magnetic properties as follows: Maximum magnetic energy product (BH) max =310kJ / m 3 , Coercivity Hcj=12×10 6 A / m, remanence Br=11.2×10 5 A / m.

[0047] Table 1 Comparison of magnetic properties of magnetic powder bonded bodies prepared in Examples

[0048]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| magnetic energy product | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com