Copper clad laminate with low dielectric constant and manufacturing method of copper clad laminate

A low dielectric constant, copper-clad laminate technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problem of high dielectric constant of cristobalite, large product dielectric constant and dielectric loss , large dielectric loss and other problems, to achieve the effect of simple technical solution, low dielectric constant and low dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] 800g resin composition preparation

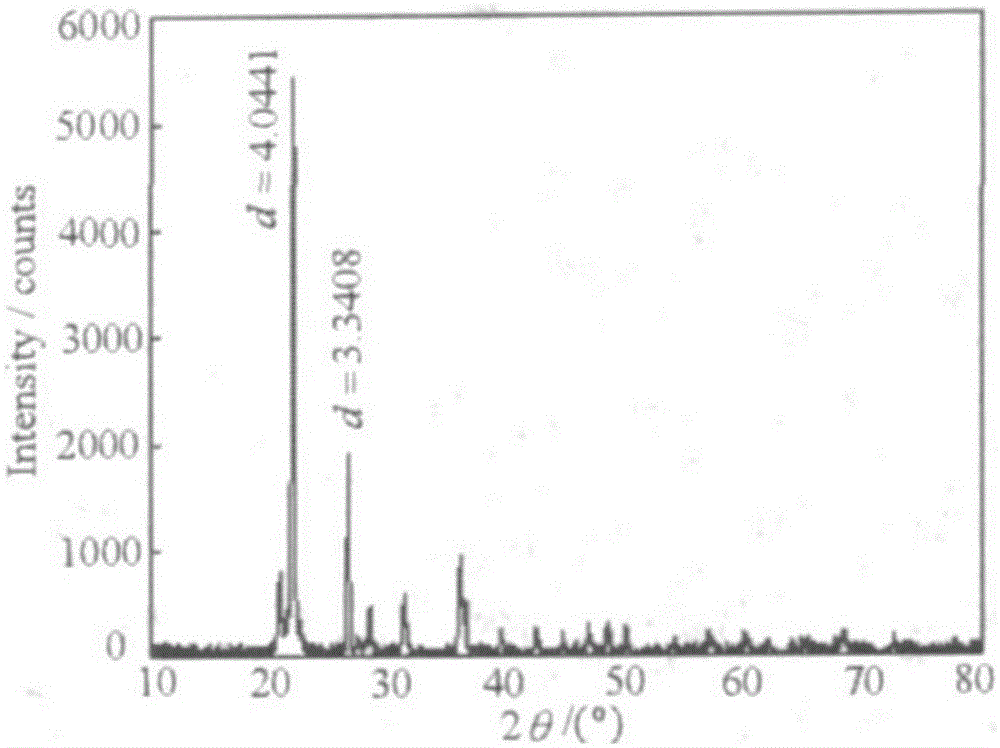

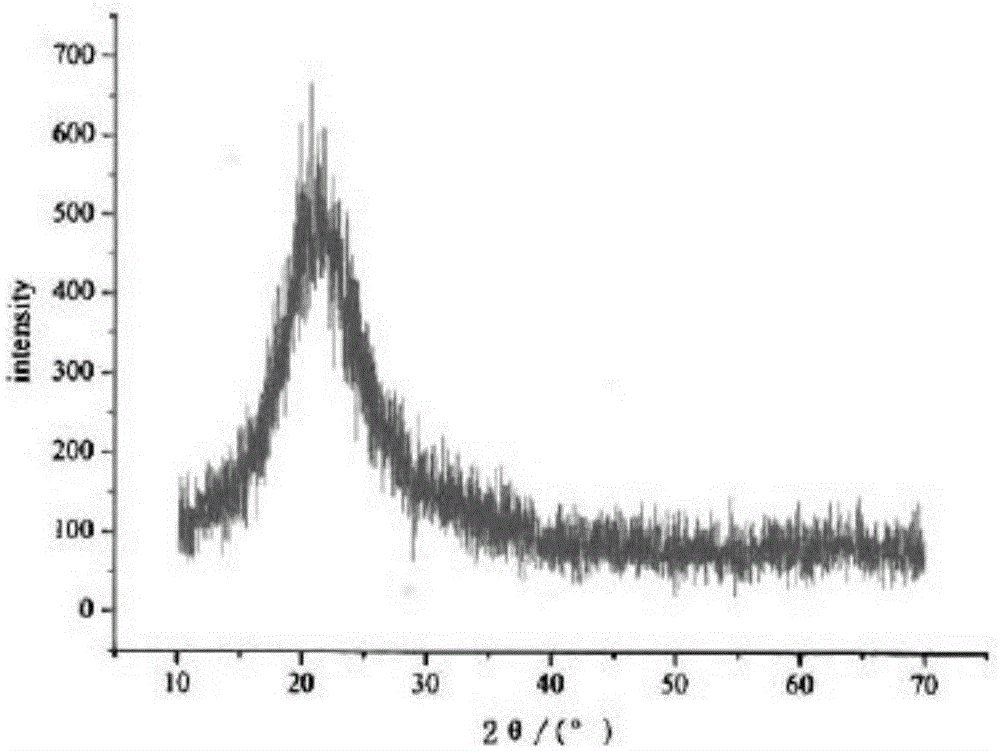

[0061] Add 20% hexaphenoxycyclotriphosphazene (Huizhou Shengshida Technology Co., Ltd., PZ-100) into a 2L high-speed shear emulsification kettle, then add 1% dimethylformamide (DMF) solvent, stir for 5 minutes to make six Dissolve and disperse phenoxycyclotriphosphazene, add 0.3% bis-methylimidazole, stir for 3 minutes to dissolve and disperse, then add 2.7% γ-glycidyl etheroxypropyl trimethoxysilane (Dow Corning, Z-6040) and stir for 5 minute, within 2 to 3 minutes, slowly add 25% cristobalite powder (this cristobalite is obtained by the following:

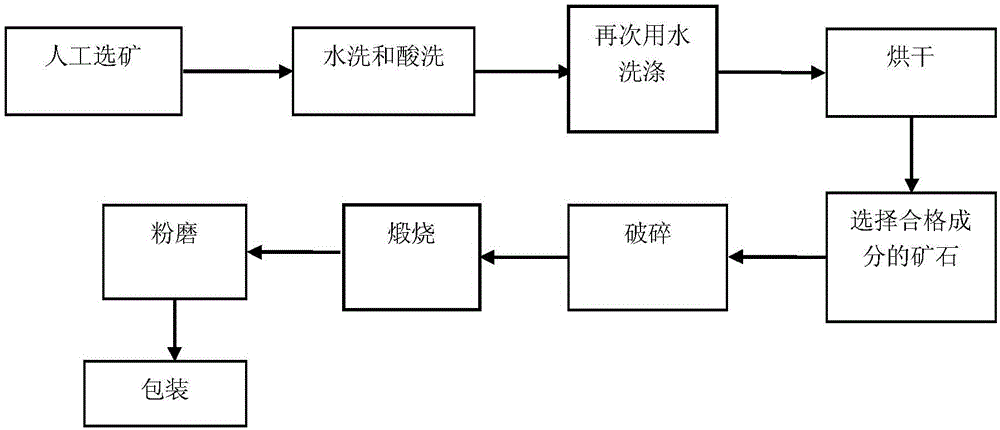

[0062] Step 1: Manually select quartz ores that do not contain black or colored impurities.

[0063] In step two, the quartz ore is washed with water and pickled.

[0064] Step 3: Take out the quartz ore and wash it with water to pH ≈ 7

[0065] Step 4, drying the quartz ore

[0066] Step 5, by chemical titration and atomic emission spectroscopy, select the quartz ore whose weight p...

Embodiment 2

[0085] Repeat Example 1 to prepare

Embodiment 3

[0090] The preparation of Example 1 was repeated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com