Composite diamond heat-dissipating material and preparing method thereof

A composite heat dissipation material and diamond technology, which is applied in the field of diamond composite heat dissipation materials and its preparation, can solve the problems of poor coating quality and unevenness of heat dissipation materials, and achieve the effects of good compactness, good film quality and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

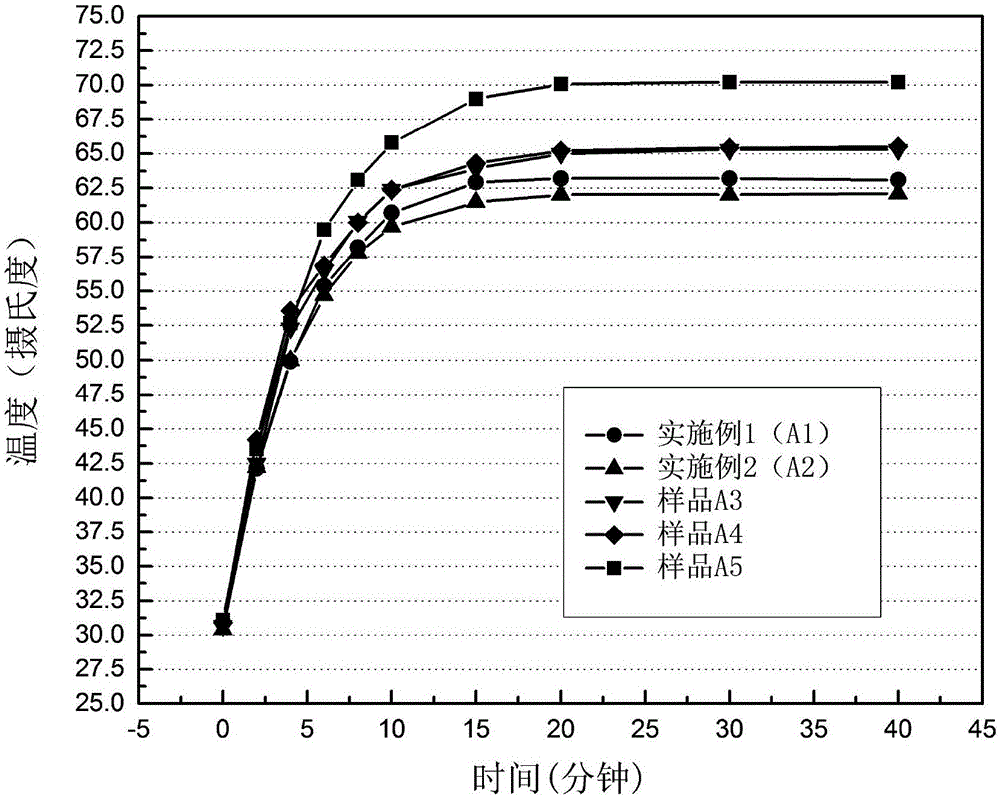

Embodiment 1

[0022] Weigh 150 grams of water-based anionic acrylic resin (solid content about 50%) and 5 grams of defoaming agent; pour it into 450 Form solution A in 1 gram of deionized water (conductivity less than 5us / cm); weigh 1.5 grams of diamond micropowder (particle size W1.5, the same below), 2 grams of carbon nanotubes (length 50um, the same below), and grind evenly After mixing, then use 50 grams of deionized water and 0.3 grams of dispersant to disperse the composite material of diamond and carbon nanotubes to form solution B; then pour solution B into solution A while stirring in ultrasonic hydrothermal to form electrophoresis Liquid C is then poured into the electrophoresis tank; the metal radiator is set as the anode after degreasing, alkali corrosion and other preliminary processes, and the stainless steel plate is set as the cathode, and a 100V DC voltage is applied for 40 seconds; the sample is taken out and washed with deionized water Then put it into a high-temperature ...

Embodiment 2

[0024] Weigh 150 grams of water-based anionic acrylic resin (solid content about 50%) and 5 grams of defoamer, and pour them into 450 grams of deionized water (conductivity less than 5us / cm) while stirring in an ultrasonic hydrothermal environment to form Solution A: Weigh 5 grams of diamond powder, tourmaline powder (particle size 10,000 mesh, the same below), and carbon nanotubes (by weight ratio 1.5:1.5:2) and mix evenly, then use 50 grams of deionized water and 0.4 grams of The dispersant disperses the composite material of diamond, tourmaline and carbon nanotubes to form solution B; then pour solution B into solution A while stirring in ultrasonic hydrothermal to form electrophoretic solution C and pour it into the electrophoresis tank; The radiator is set as the anode after degreasing, alkali etching and other preliminary processes, and the stainless steel plate is set as the cathode, and a DC voltage of 100V is applied for 40 seconds; the sample is taken out, washed with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com