Preparation method of magnesium stearate modified magnesium powder magnesium-rich primer

A technology of magnesium stearate and magnesium powder, applied in epoxy resin coatings, fibrous fillers, coatings, etc., can solve the problems of consuming magnesium powder and changing the surface morphology of magnesium powder, so as to prolong the service life and improve the utilization rate. rate and speed up the application process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation method of magnesium stearate modified magnesium powder magnesium-rich primer is carried out according to the following steps:

[0032] 1. Preparation of modified magnesium stearate powder: First, add 100 mL of butyl acetate to a 250 mL Erlenmeyer flask. Weigh 70 mg of magnesium stearate, add it into the butyl acetate solution, and stir magnetically to obtain the mixed solution a. Weigh 8.0 g of 400-mesh magnesium powder, add it to a, and stir at 20° C. for 24 hours to obtain magnesium stearate-modified magnesium powder butyl acetate mixture b.

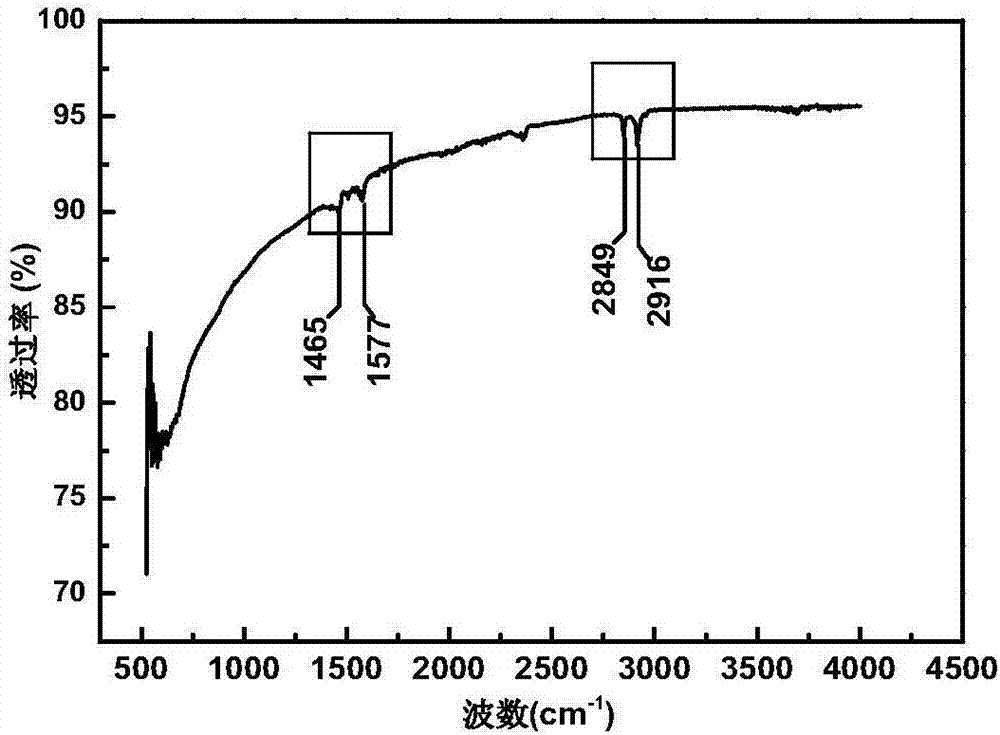

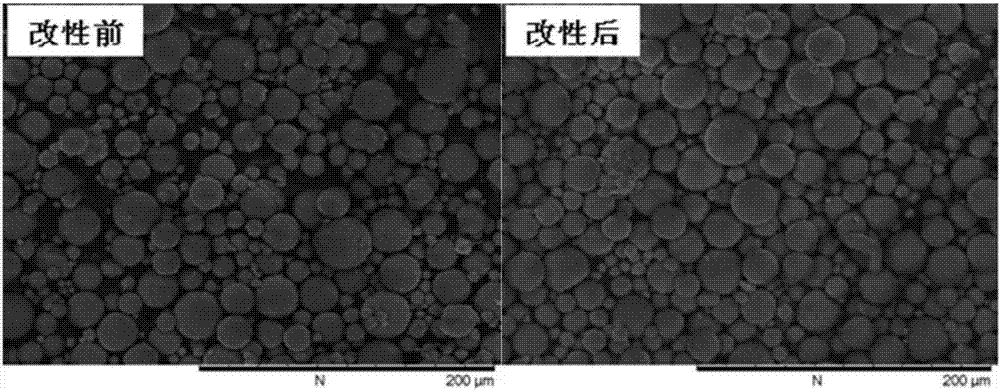

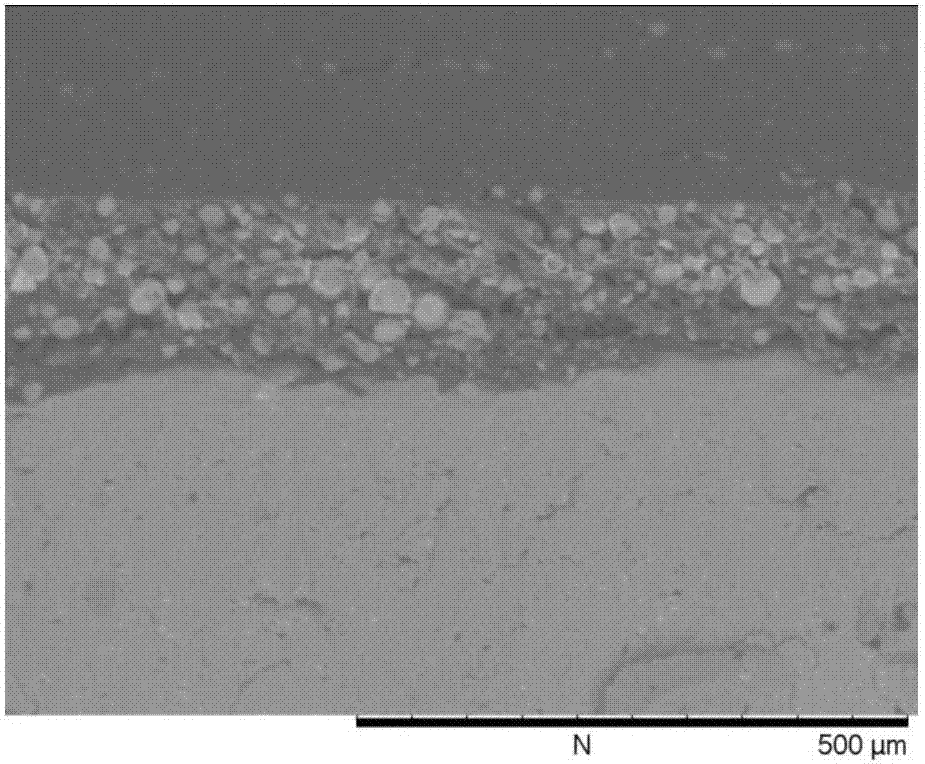

[0033] 2. Filter the magnesium stearate-modified magnesium powder butyl acetate mixture b prepared in step 1, and dry the filtered magnesium powder at room temperature for 48 hours, that is, the magnesium stearate-modified magnesium powder. Magnesium powder and magnesium stearate modified magnesium powder were characterized by infrared (see figure 1 ). Modified magnesium powder at 1465 and 1577cm -1 The chara...

Embodiment 2

[0041] 1. Preparation of magnesium stearate modified magnesium powder: First, add 120 mL of butyl acetate to a 250 mL Erlenmeyer flask. Weigh 84 mg of magnesium stearate, add it into the butyl acetate solution, and stir magnetically to obtain the mixed solution a. Weigh 9.6 g of 400-mesh magnesium powder, add it to a, and stir at 20° C. for 48 h to obtain magnesium stearate-modified magnesium powder butyl acetate mixture b.

[0042] 2. Filter the magnesium stearate-modified magnesium powder butyl acetate mixture b prepared in step 1, and dry the filtered magnesium powder at room temperature for 48 hours, that is, the magnesium stearate-modified magnesium powder.

[0043] 3. Preparation of the 2024 aluminum alloy substrate: Cut the 2024 aluminum alloy into small pieces of 50 mm×50 mm. Grind with 140#, 400#, 600# and 800# sandpaper respectively, clean the polished substrates with distilled water and absolute ethanol respectively, and soak the cleaned substrates in absolute ethano...

Embodiment 3

[0048] 1. Preparation of modified magnesium stearate powder: First, add 100 mL of butyl acetate to a 250 mL Erlenmeyer flask. Weigh 70 mg of magnesium stearate, add it into the butyl acetate solution, and stir magnetically to obtain the mixed solution a. Weigh 8.0 g of 400-mesh magnesium powder, add it to a, and stir at 20° C. for 24 hours to obtain magnesium stearate-modified magnesium powder butyl acetate mixture b.

[0049] 2. Filter the magnesium stearate-modified magnesium powder butyl acetate mixture b prepared in step 1, and dry the filtered magnesium powder at room temperature for 48 hours, that is, the magnesium stearate-modified magnesium powder.

[0050] 3. Preparation of the 2024 aluminum alloy substrate: Cut the 2024 aluminum alloy into small pieces of 50 mm×50 mm. Grind with 140#, 400#, 600# and 800# sandpaper respectively, clean the polished substrates with distilled water and absolute ethanol respectively, and soak the cleaned substrates in absolute ethanol fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com