Low-noise lubricating grease and preparation method thereof

A grease, low-noise technology, applied in the field of low-noise grease and its preparation, can solve the problem of poor noise reduction effect of low-noise grease, and achieve the effects of excellent anti-wear, noise reduction and excellent extreme pressure performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

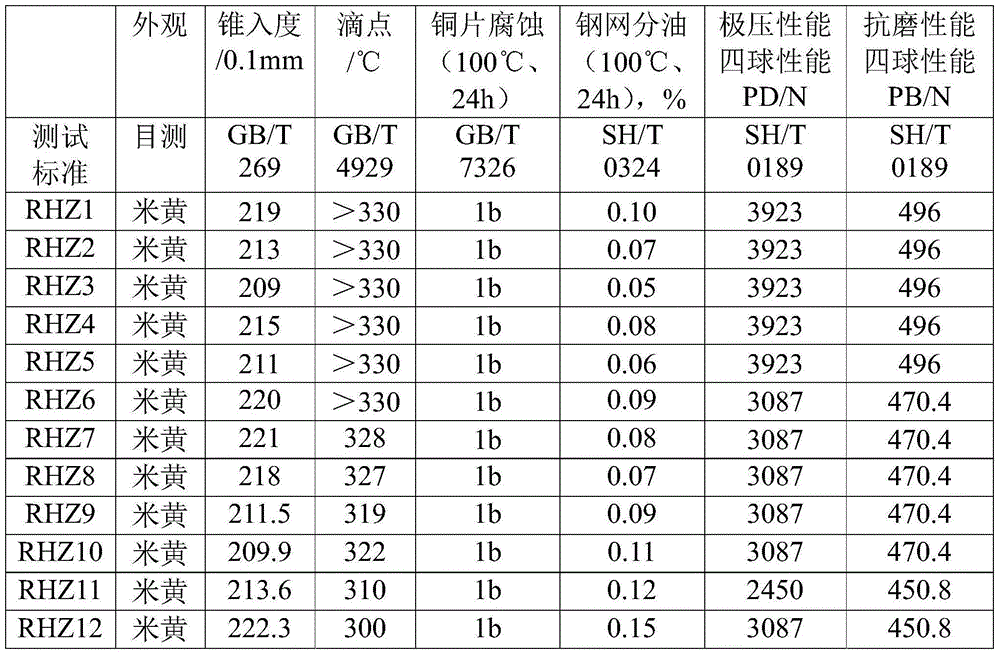

Examples

Embodiment 1

[0021] This embodiment provides a low-noise lubricating grease suitable for use in a juice extractor, and a preparation method of the low-noise lubricating grease. The preparation method sequentially includes the steps of material preparation, premix preparation, reaction, high-temperature refining and preparation, as follows:

[0022] (1) material preparation

[0023] Weigh 690g base oil (350g mineral oil, 340g synthetic oil), 100g organic amine (20g decylamine, 30g octylamine, 30g dodecylamine, 20g tetradecylamine), 180g diisocyanate (90gMDI, 90gTDI), 10g extreme pressure Anti-wear agent (4gT321A, 3gT405A, 2gT361A, 1gT306), 10g solid filler (1g nano-calcium carbonate, 4g nano-calcium silicate, 5g polytetrafluoroethylene powder), 10g antioxidant (3g diphenylamine, 6g2,6-di tert-butyl p-cresol, 1g phenyl-β-naphthylamine), for subsequent use.

[0024] (2) Preparation of premix: take out half of the total amount of base oil, and dissolve organic amine and catalyst (T-9, the do...

Embodiment 2

[0030] This embodiment provides a low-noise lubricating grease suitable for use in a juice extractor, and a preparation method of the low-noise lubricating grease. The preparation method sequentially includes the steps of material preparation, premix preparation, reaction, high-temperature refining and preparation. In this example, only the raw materials used to prepare grease are different from those in Example 1, and the steps of making lye, reaction steps, high-temperature refining steps and preparation steps are completely consistent with those in Example 1. The raw materials used to prepare grease are as follows:

[0031] Weigh 690g base oil (300g mineral oil, 390g synthetic oil), 100g organic amine (50g dodecylamine, 20g tetradecylamine, 30g octadecylamine), 180g diisocyanate (60gMDI, 60gTDI, 60gH-MDI), 10g pole Pressure antiwear agent (2gT306, 2gT307, 1gT308, 5gT309), 10g solid filler (3g boron nitride powder, 1g melamine powder, 1g nano aluminum silicate, 4g zinc oxid...

Embodiment 3

[0034] This embodiment provides a low-noise lubricating grease suitable for use in a juice extractor, and a preparation method of the low-noise lubricating grease. The preparation method sequentially includes the steps of material preparation, premix preparation, reaction, high-temperature refining and preparation. In this example, only the raw materials used to prepare grease are different from those in Example 1, and the steps of making lye, reaction steps, high-temperature refining steps and preparation steps are completely consistent with those in Example 1. The raw materials used to prepare grease are as follows:

[0035] Weigh 690g base oil (200g mineral oil, 490g synthetic oil), 100g organic amine (60g dodecylamine, 30g hexadecylamine, 10g octadecylamine), 180g diisocyanate (MDI), 10g extreme pressure antiwear agent (5gT308 , 5gT309), 10g solid filler (5g boron nitride powder, 5g melamine powder), 10g antioxidant (3g phenyl-β-naphthylamine, 7g phenyl-α-naphthylamine), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com