Preparation method and application of lithium vanadate nonlinear optical crystal

A technology of nonlinear optics and lithium vanadate, applied in nonlinear optics, chemical instruments and methods, optics, etc., can solve problems such as no single crystal, and achieve the effects of simple operation, fast growth speed, and short growth cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Take reaction formula (1) as an example, but not limited to reaction formula (1):

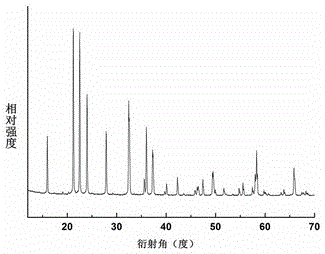

[0033] Using the high-temperature solid-phase method, the reaction formula 3Li 2 CO 3 +V 2 o5 →2Li 3 VO 4 +3CO 2 -

[0034] Lithium vanadate (Li 3 VO 4 ) compound: the Li 2 CO 3 , V 2 o 5 Put it into a mortar according to the stoichiometric ratio of 3:1, mix and grind it carefully, then put it into a corundum crucible with an opening of Φ100mm×100mm, press it tightly, put it into a muffle furnace, and slowly raise the temperature to 400°C, constant temperature 10 hours, take out the crucible after cooling, take out the sample and re-grind evenly, then put it in the crucible, keep the temperature in the muffle furnace at 550°C for 48 hours, take it out, put it into the mortar and grind it to get the lithium vanadate compound, Carry out X-ray analysis to this product, the obtained X-ray spectrogram is consistent with the reported result;

[0035] a. The lithium vanadate polycr...

Embodiment 2

[0041] Take reaction formula (2) as an example, but not limited to reaction formula (2):

[0042] Using the high-temperature solid-phase method, the reaction formula 6LiOH+V 2 o 5 →2Li 3 VO 4 +3H 2 O-

[0043] Lithium vanadate (Li 3 VO 4 ) compound, the specific operation steps are carried out according to Example 1;

[0044] The synthesized Li 3 VO 4 Compound and Flux PbF 2 Mix according to a molar ratio of 1:2, put it into an open platinum crucible of Φ60mm×60mm, raise the temperature to 530°C, keep the temperature for 60 hours and then cool down to 450°C to obtain a mixed melt of lithium vanadate and flux;

[0045] Bind the seed crystal obtained in step b of Example 1 to the lower end of the seed rod with a platinum wire, introduce the seed crystal into a place about 1-2 cm away from the crucible through a small hole on the top of the furnace, keep the temperature at a constant temperature for 20 minutes, and then immerse it below the liquid level of the mixed mel...

Embodiment 3

[0049] Take reaction formula (3) as an example, but not limited to reaction formula (3):

[0050] Using the high-temperature solid-phase method, the reaction formula 6LiNO 3 +V 2 o 5 →2Li 3 VO 4 +3NO-+3NO 2 -+3O 2 -Synthesis of lithium vanadate (Li 3 VO 4 ) compound, the specific operation steps are carried out according to Example 1;

[0051] The synthesized Li 3 VO 4 Compound and Flux PbF 2 Mix according to a molar ratio of 1:3, put it into an open platinum crucible of Φ70mm×70mm, heat up to 450°C, keep the temperature for 1 hour and then cool down to 380°C to obtain a mixed melt of lithium vanadate and flux;

[0052] Bind the seed crystal obtained in Step b of Example 1 to the lower end of the seed rod with a platinum wire, introduce the seed crystal into a place about 1-2 cm away from the crucible through a small hole on the top of the furnace, keep the temperature at a constant temperature for 5 minutes, and then immerse it below the liquid level of the mixed m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com