Application of fabric darkening agent in darkening of real silk fabric

A technology of silk fabric and darkening agent, which is applied in the direction of animal fiber, textiles, papermaking, fiber treatment, etc., can solve the problems of difficult-to-apply fabrics, etc., and achieve the effect of deepening durability, obvious effect, and low refractive index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] At room temperature of 25°C, weigh 100g of deionized water and add it to 50g of silicon dioxide aqueous dispersion (average particle size 20-25nm, solid content 30%, Zhejiang Yuda Chemical Co., Ltd., ZS-30), After mechanically stirring and mixing evenly, add 1.5g PEG400 (polyethylene glycol, number average molecular weight is 400) dropwise, fully stir to make it evenly mixed, the prepared mixed solution of silicon dioxide and PEG400 is called product 1, the solid content 10%.

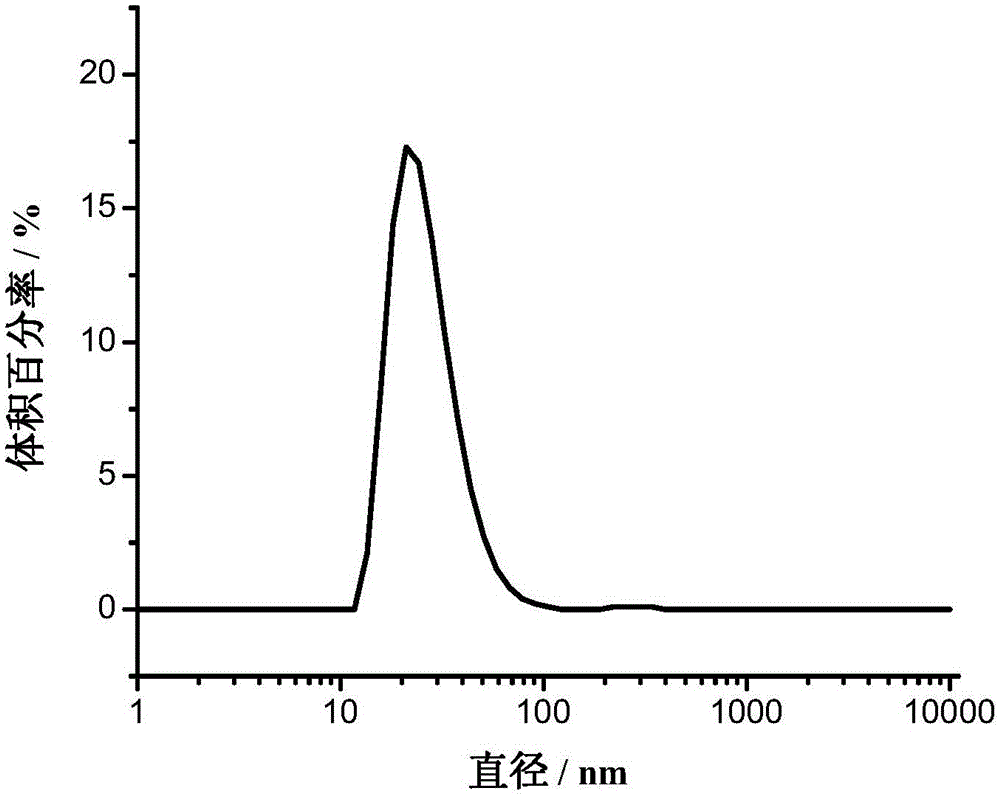

[0052] After the product 1 is diluted, the particle size distribution curve is measured by a Malvern nanometer particle size analyzer, as shown in figure 1 shown. It can be seen from the figure that the particle size of product 1 is about 21nm, and the particle size distribution is stable.

Embodiment 2

[0054] Under the condition of room temperature 25°C, weigh 100g of silicon dioxide aqueous dispersion (solid content 30%, average particle size 20-25nm, Zhejiang Yuda Chemical Co., Ltd., ZS-30) into 150g of deionized water, mechanically After stirring and mixing evenly, add 4.5g PEG600 dropwise, fully stir and make it uniformly mixed, the mixed solution of the prepared silicon dioxide and PEG600 (polyethylene glycol, number average molecular weight is 600) is called product 2, and the solid content is 12%.

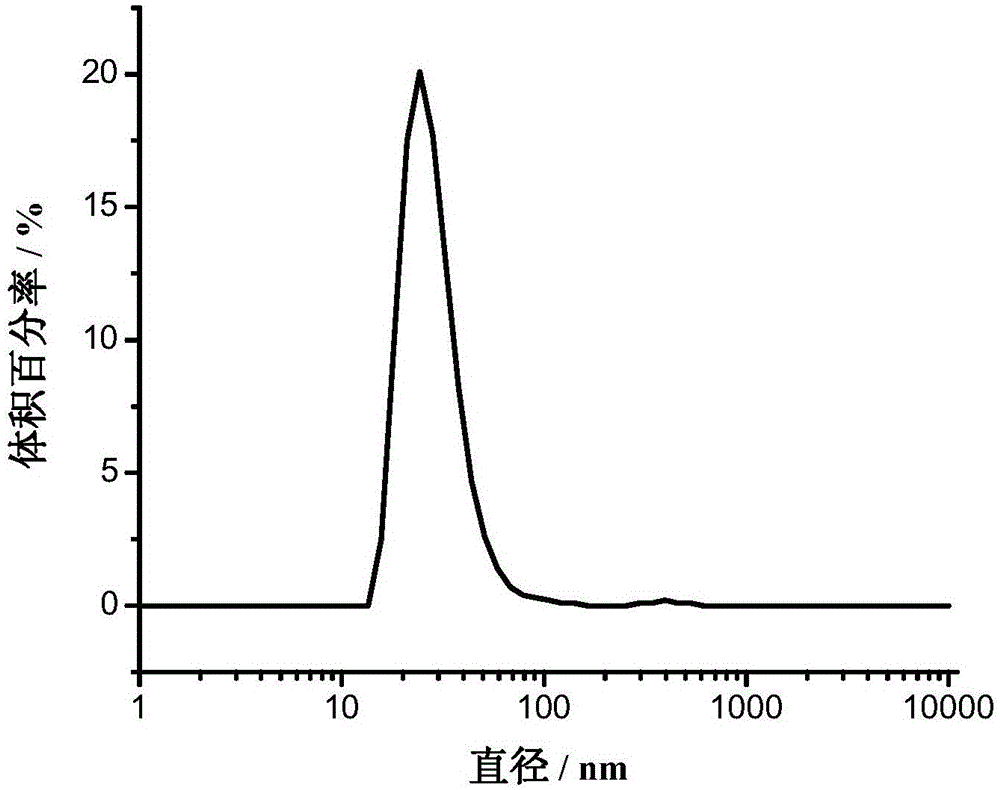

[0055] After the product 2 is diluted, the particle size distribution curve is measured by a Malvern nanometer particle size analyzer, as shown in figure 2 shown. It can be seen from the figure that the particle size of the product 2 is about 24nm, which is consistent with the particle size of the product 1 obtained in the above-mentioned Example 1. It can be seen that the amount of PEG added has no effect on the particle size of the silica.

Embodiment 3

[0057] Under the condition of room temperature 25°C, weigh 70g of silicon dioxide aqueous dispersion (solid content 30%, average particle size 20-25nm, Zhejiang Yuda Chemical Co., Ltd., ZS-30) into 180g of deionized water, mechanically After stirring and mixing evenly, 6.3gPEG200 (polyethylene glycol, number average molecular weight is 200) is added dropwise, fully stirred to make it uniformly mixed, the mixed solution of silicon dioxide and PEG200 is called product 3, and the solid content is 8.4%.

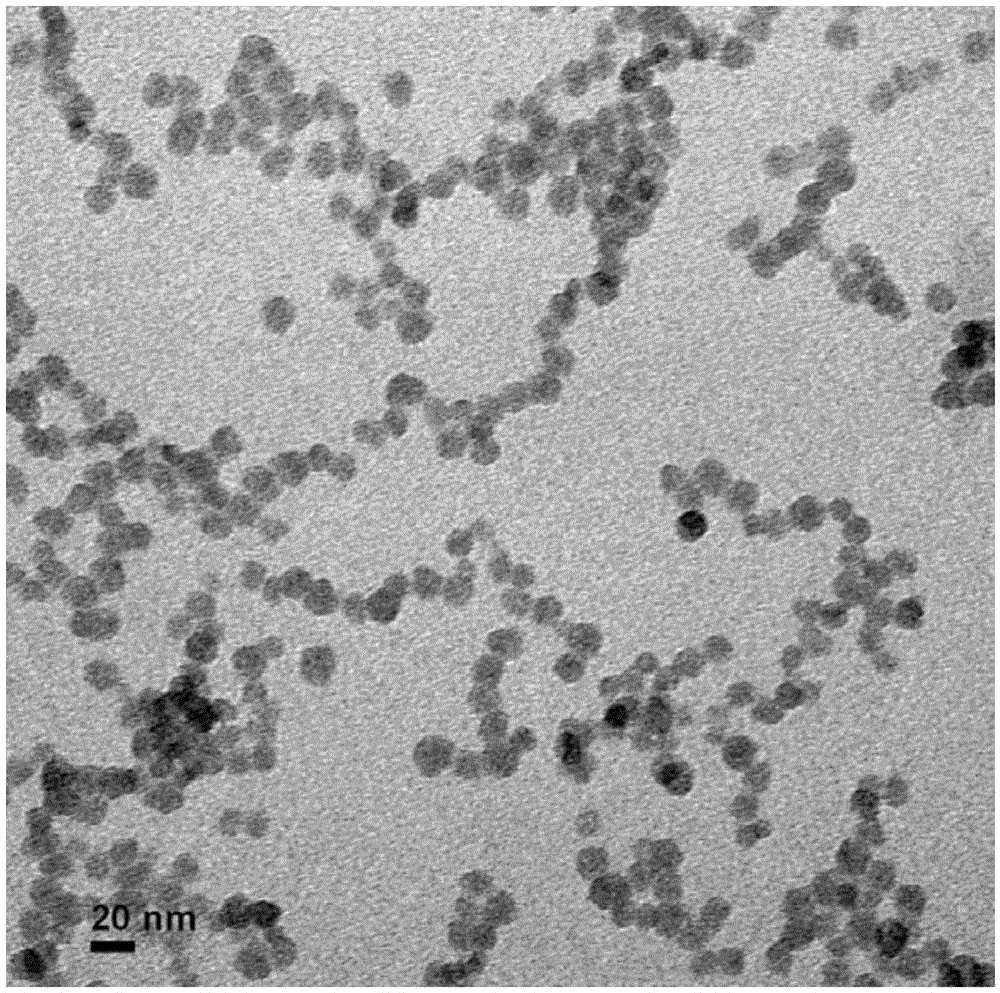

[0058] The transmission electron micrograph of the product 3 that embodiment 3 obtains is as image 3 as shown, Figure 4 It is a transmission electron micrograph of commercial silicon dioxide (i.e., silicon dioxide in an aqueous dispersion of silicon dioxide). Depend on image 3 and Figure 4 It can be seen that after adding PEG200, the mixed solution of silica and PEG200 has no obvious difference in nanoparticle morphology compared with commercial silica, and still maintain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com