A built-in synthetic leather lean terminal heating system and method

A heat supply system and synthetic leather technology, which is applied in the field of heat supply technology with high operational flexibility, can solve the problems of synthetic leather cannot be produced normally, uneven temperature distribution, poor exhaust, etc., and achieve simple and novel structure and flexible operation Great, reduce heat loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

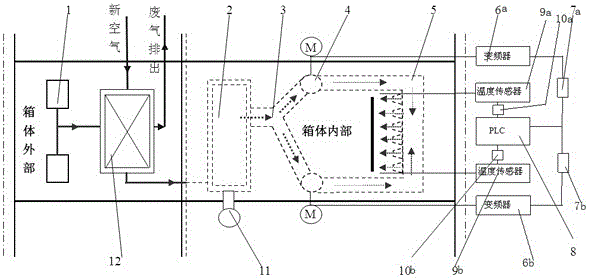

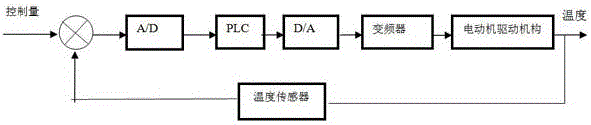

[0015] The technical solution of the present invention to solve the above problems is as follows: a built-in synthetic leather lean terminal heating system, which is characterized in that it includes a box body, a natural gas flue gas generating chamber 2, a natural gas burner 11, a hot air equalizing conduit 3, Circulating air duct 5 in the box, air preheater 12 and automatic control system for uniform temperature distribution; the outlet of the natural gas burner 11 is connected to the inlet side of the natural flue gas generating chamber 2; the hot air equalizing duct 3 is fixed to the natural gas The flue gas generating chamber 2, the thermal fluid inlet side of which is connected to the flue gas outlet channel of the natural gas flue gas generating chamber 2; The left and right inlets of the circulating air duct 5 are connected to the hot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com