Preparation method of polysaccharide-polyvinyl alcohol embolism microsphere

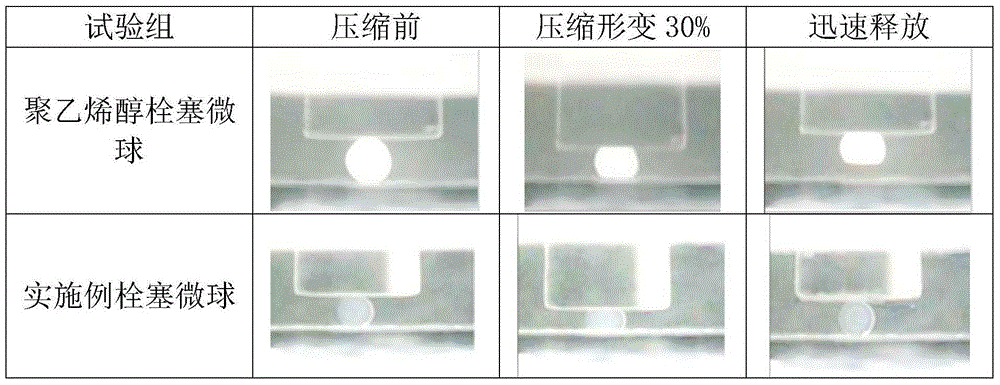

A technology of polyvinyl alcohol embolic microspheres and polyvinyl alcohol, which is applied in the preparation of interventional vascular embolization materials and the preparation of polysaccharide-polyvinyl alcohol embolic microspheres. Material lesions have not recovered, and the action time is uncontrollable, etc., to achieve the effects of convenient clinical application, uniform and controllable particle size, large scalability and elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of the polysaccharide-polyvinyl alcohol embolization microspheres includes the following main processes: 1) preparation of blend solution; 2) emulsification and cross-linking; 3) washing, dehydration and drying; 4) sieving. Specific steps are as follows:

[0035] Step 1: Preparation of blend liquid: dissolve polyvinyl alcohol and polysaccharide natural polymer in water, stir with an electric stirrer at a stirring rate of 500-5000 rpm, and prepare a blend with a concentration of 1-30% (w / w) solution. Wherein, the mass ratio (w / w) of polysaccharide and polyvinyl alcohol is 1:0.01-3:1.

[0036] Among them, the polysaccharide natural polymer mainly includes pullulan, chitosan or carboxymethyl cellulose. The blending solution is blended with one of polyvinyl alcohol and polysaccharide macromolecule, and the different ratios of the two materials can control the action time of the embolic microspheres.

[0037] Among them, after blending chitosan and ...

Embodiment 1

[0051] Embodiment 1, chitosan-polyvinyl alcohol embolization microspheres

[0052] Step 1: Preparation of blend solution: dissolving polyvinyl alcohol and chitosan natural polymer in water, stirring with an electric stirrer at a stirring rate of 500-5000 rpm, and preparing 1000 ml of blend solution with a concentration of 10% (w / w). Wherein, the mass ratio (w / w) of chitosan and polyvinyl alcohol is 1:0.01, 1:0.1, 1:3, respectively.

[0053] Step 2: emulsification and crosslinking: Heat 500ml of the chitosan-polyvinyl alcohol blend prepared in step 1 to 90°C, stir at 5000rpm for 30min to dissolve it into a transparent liquid, and let stand to remove air bubbles. After dispersing 0.01% (w / w) Span80 and 500ml liquid paraffin evenly, add it dropwise to the liquid paraffin with a syringe, after stirring for 60 minutes, add 0.01% (w / w) glutaraldehyde with a syringe, Stirring was continued for 3h. At the same time, inject the remaining uncrosslinked blend in step 1 into the crossli...

Embodiment 2

[0056] Embodiment 2, starch-polyvinyl alcohol embolization microspheres

[0057] Step 1: Preparation of blend solution: Dissolve polyvinyl alcohol and starch in water, stir with an electric stirrer at a stirring rate of 1000 rpm, and prepare 1000 ml of blend solution with a concentration of 15% (w / w). Wherein, the mass ratio (w / w) of starch and polyvinyl alcohol is 0.1:1, respectively.

[0058] Step 2: emulsification and crosslinking: Heat 500ml of the starch-polyvinyl alcohol blend prepared in step 1 to 90°C, stir at 3000rpm for 20min to dissolve it into a transparent liquid, and let it stand to remove air bubbles. Disperse 0.02% (w / w) Span80 and 500ml liquid paraffin evenly, then add it dropwise into the liquid paraffin with a syringe, stir for 40 minutes, then add 0.02% (w / w) formaldehyde with a syringe, and keep stirring 6h. At the same time, the remaining uncrosslinked blend solution in step 1 is injected into the crosslinked solution into the crosslinked solution to fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com