Preparation method for electron beam irradiation modified graphite-like-phase carbon nitride for visible-light-driven photocatalyst

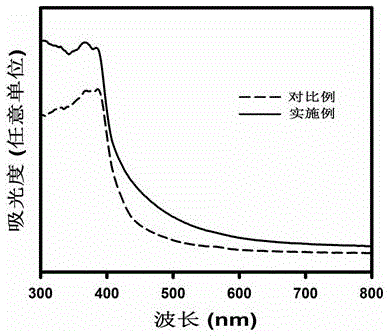

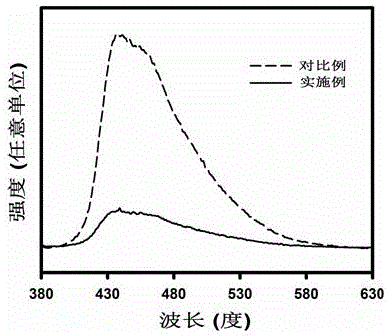

A technology of graphite phase carbon nitride and electron beam irradiation, which is applied in chemical instruments and methods, physical/chemical process catalysts, light water/sewage treatment, etc., can solve the problem of low direct photocatalytic efficiency and achieve effective promotion Separation, easy operation, enhanced absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0018] The process and steps of this embodiment are as follows:

[0019] a. First prepare graphite-like carbon nitride according to existing known technology: get 4.0g urea and add a 25mL crucible with a cover, and put it into a muffle furnace, dry at 80°C for 24 hours, and then heat up to 550°C °C thermal polymerization for 3 hours, then naturally cooled to room temperature. The resulting yellow solid was washed several times with water and dilute nitric acid solution, and finally dried at 60 °C overnight.

[0020] b. Mix 60 mg of the graphite-like carbon nitride synthesized above, 30 g of water, 3 g of isopropanol and 60 mg of concentrated ammonia water and seal them in a polyethylene bag. The bag is placed under an electron accelerator for room temperature irradiation treatment. The irradiation dose was set at 800kGy.

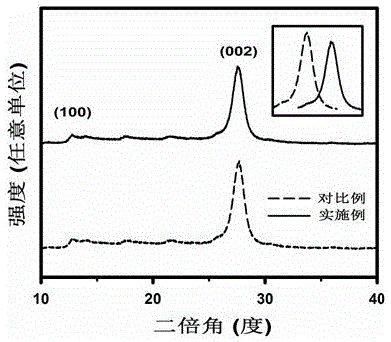

[0021] c. After conventional centrifugation, washing and drying of the suspension after irradiation in the previous step, the graphite-like carbon nitrid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com