Asynchronous Hot Rolling Process for Large Size Stainless Steel-Copper Alloy Clad Sheet

A composite sheet and stainless steel sheet technology, applied in the direction of metal rolling, etc., can solve the problems of inability to prepare large-size long composite sheets, easy peeling of the interface, peeling strength, and easy oxidation of the surface of metal materials, etc., to achieve good mechanical properties and high peeling strength, reducing the effect of intermediate annealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

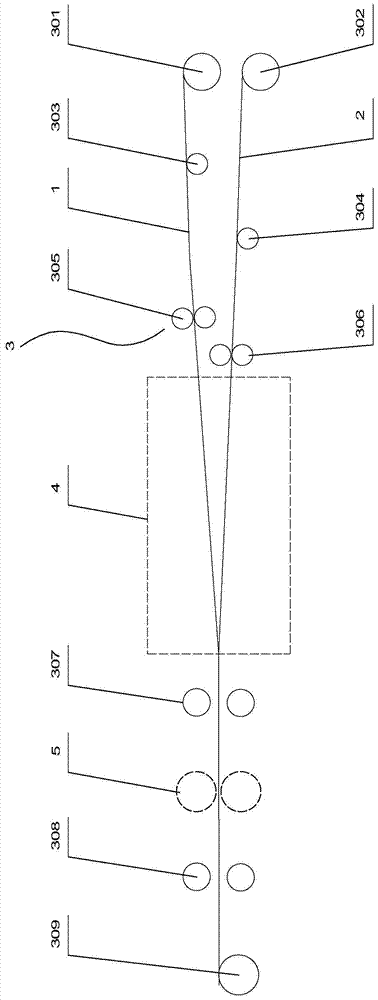

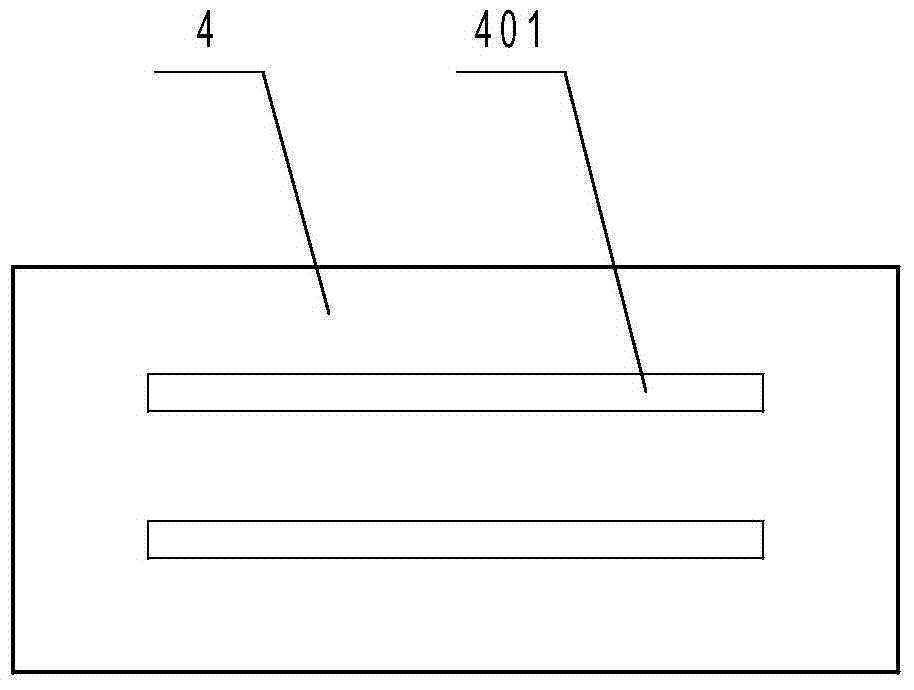

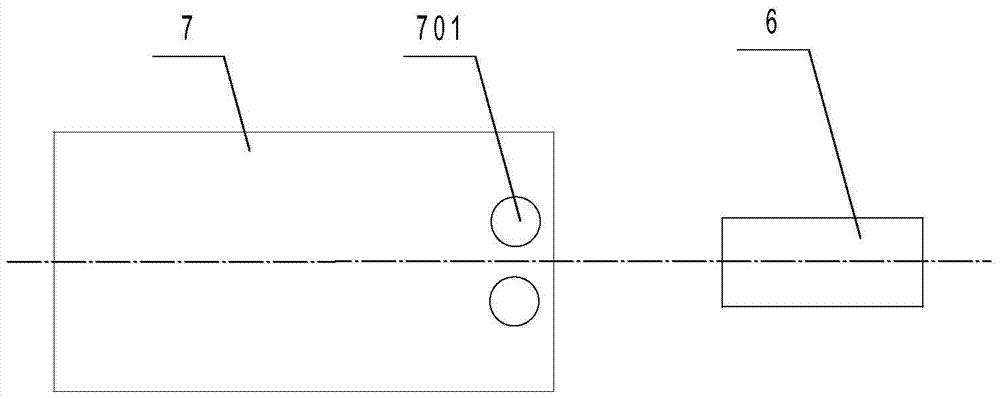

[0059] A kind of asynchronous hot rolling process of large-scale stainless steel-copper alloy composite plate, the process comprises the following steps:

[0060] ① Select composite panels:

[0061] Select the stainless steel plate 1 and the copper alloy plate 2 that make up the composite plate according to the required size, among which: the stainless steel plate 1 is a stainless steel plate with a stainless steel grade of 304, and the copper alloy plate 2 is a brass plate. The width of the plate is 300mm and the thickness is 0.3mm. , length=5000mm;

[0063] Use a steel wire roller brush with a steel wire diameter of 0.1mm to perform mechanical automatic roller brushing on the interface to be compounded of the stainless steel plate and the copper alloy plate;

[0064] ③Heating treatment:

[0065] The stainless steel plate and the copper alloy plate are aligned by the open-loop servo low-speed conveying system 3, and the ends are riveted or w...

Embodiment 2

[0084] A kind of asynchronous hot rolling process of large-scale stainless steel-copper alloy composite plate, the process comprises the following steps:

[0085] ① Select composite panels:

[0086] Select the stainless steel plate 1 and the copper alloy plate 2 that make up the composite plate according to the required size, wherein: the stainless steel plate 1 is a stainless steel plate with a stainless steel grade of 316, and the copper alloy plate 2 is a bronze plate. The width of the plate is 800mm, the thickness is 3mm, and the length =6000mm;

[0088] Use a steel wire roller brush with a steel wire diameter of 0.4mm to perform mechanical automatic roller brushing on the interface to be composited of the stainless steel plate and the copper alloy plate;

[0089] ③Heating treatment:

[0090] The stainless steel plate and the copper alloy plate are aligned by the open-loop servo low-speed conveying system 3, and the ends are riveted or we...

Embodiment 3

[0109] A kind of asynchronous hot rolling process of large-scale stainless steel-copper alloy composite plate, the process comprises the following steps:

[0110] ① Select composite panels:

[0111] Select the stainless steel plate 1 and the copper alloy plate 2 that make up the composite plate according to the required size, wherein: the stainless steel plate 1 is a stainless steel plate with a stainless steel grade of 203, and the copper alloy plate 2 is a brass plate. The width of the plate is 1200mm, and the thickness is 6mm. length=7000mm;

[0112] ②Steel brush grinding:

[0113] Use a steel wire roller brush with a steel wire diameter of 0.4mm to perform mechanical automatic roller brushing on the interface to be composited of the stainless steel plate and the copper alloy plate;

[0114] ③Heating treatment:

[0115] The stainless steel plate and the copper alloy plate are aligned by the open-loop servo low-speed conveying system 3, and the ends are riveted or welded ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com