Long-service life and high-viscosity building material self-adhered protective film

A self-adhesive protective film, high-viscosity technology, used in layered products, synthetic resin layered products, chemical instruments and methods, etc., can solve the problems of self-adhesive film performance, late research start, etc., to achieve strong synergy, Good compatibility, mild formula effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the embodiments, so that those skilled in the art can implement it with reference to the description.

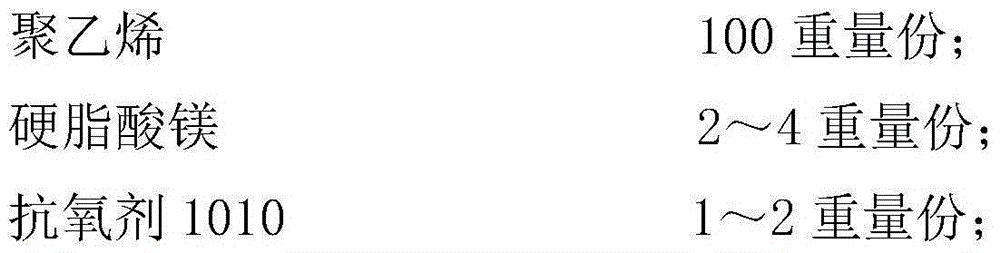

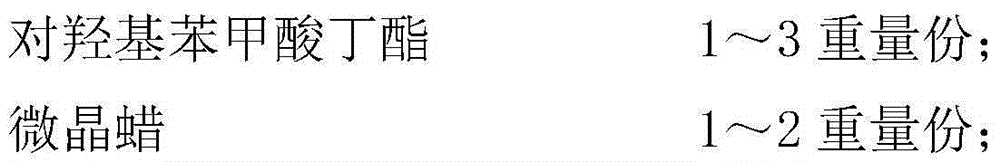

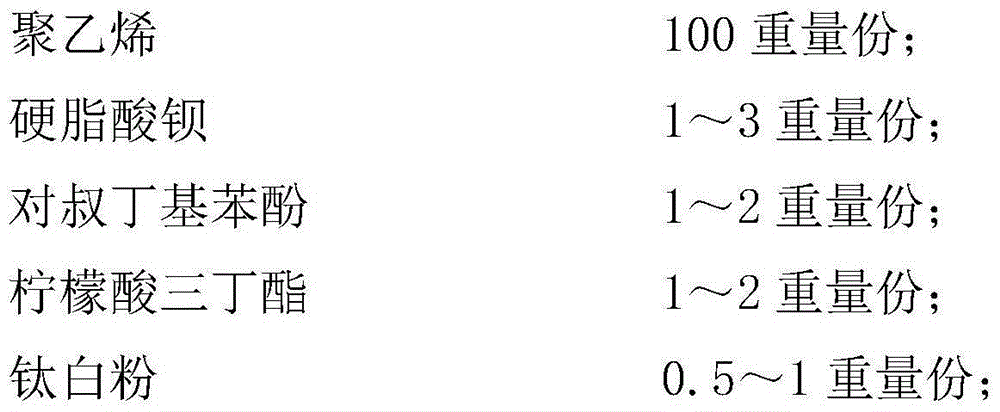

[0024] This case proposes a high-life and high-viscosity building material self-adhesive protective film of an embodiment, which includes a surface layer, a middle layer and an inner layer, wherein the surface layer includes the following materials by weight:

[0025]

[0026] Magnesium stearate acts as a stabilizer and lubricant. Compared with calcium stearate, it is more suitable for polyethylene systems; the scientific name of antioxidant 1010 is tetrakis[β-(3,5-di-tert-butyl- 4-Hydroxyphenyl) propionate] pentaerythritol ester is a low-toxic antioxidant with strong compatibility in the polyethylene system and will not be precipitated from the system due to rejection reactions with other additives; it is used for microcrystalline wax It is used to improve the weather resistance of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com