Wastewater treatment method

A treatment method and waste water technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem that the water recovery rate cannot be effectively improved, and achieve fast treatment speed and high treatment efficiency. The effect is good and the process is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

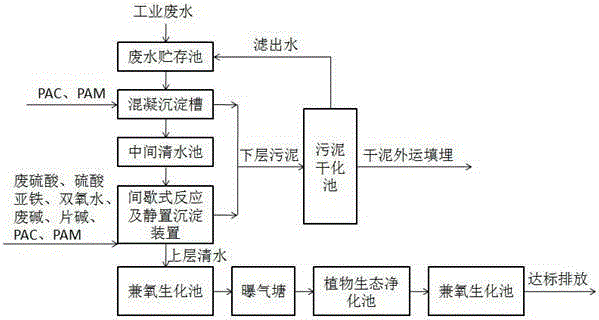

[0025] Embodiment 1: In the treatment method of the waste water, the oxidative coagulation equipment selects intermittent reaction and static sedimentation device, the treatment method of the waste water is secondary purification and secondary precipitation, and the system for treating waste water includes a waste water storage tank and a coagulation sedimentation tank , intermediate clear water tank, intermittent reaction and static sedimentation device, sludge drying tank, facultative biochemical tank, aeration pond, plant ecological purification tank, sand and gravel infiltration tank and clear water storage tank; the specific process flow is:

[0026] (1) Concentrating industrial wastewater into the wastewater storage pool; the wastewater storage pool also has a pre-cooling function to obtain cooled industrial wastewater;

[0027] (2) Introduce the cooled industrial wastewater obtained in step (1) into the coagulation sedimentation tank, and add coagulant polyaluminum chlor...

Embodiment 2

[0035] Embodiment 2: In the treatment method of this waste water, the oxidation coagulation equipment selects catalytic oxidation reaction and neutralization coagulation sedimentation tank, and the treatment method of this waste water is secondary purification, secondary precipitation, and the system for processing waste water includes waste water storage tank, coagulation Sedimentation tank, intermediate clear water tank, catalytic oxidation reaction and neutralization coagulation sedimentation tank, sludge drying tank, facultative biochemical tank, aeration pond, plant ecological purification tank, sand and gravel infiltration tank and clear water storage tank; specific process The process is:

[0036] (1) Concentrating industrial wastewater into the wastewater storage pool; the wastewater storage pool also has a pre-cooling function to obtain cooled industrial wastewater;

[0037] (2) Introduce the cooled industrial wastewater obtained in step (1) into the coagulation sedim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com