Building brick produced by using fly ash or residues obtained after burning domestic wastes, and production method thereof

A domestic waste incineration and waste incineration technology, applied in the field of building materials, can solve the problems of low utilization rate of fly ash, complicated process, high cost, etc., and achieve the effect of low cost, simple process and qualified frost resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

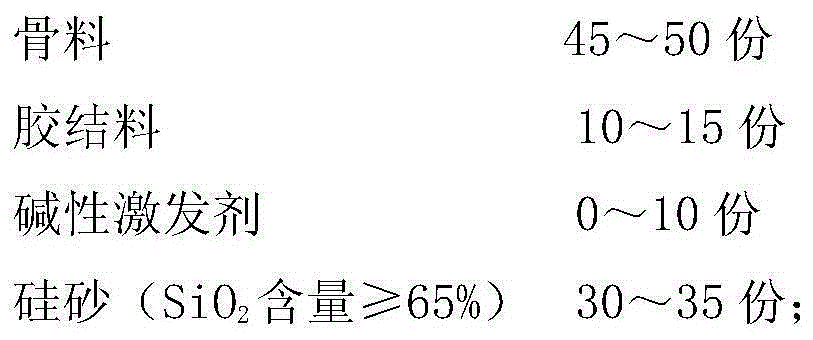

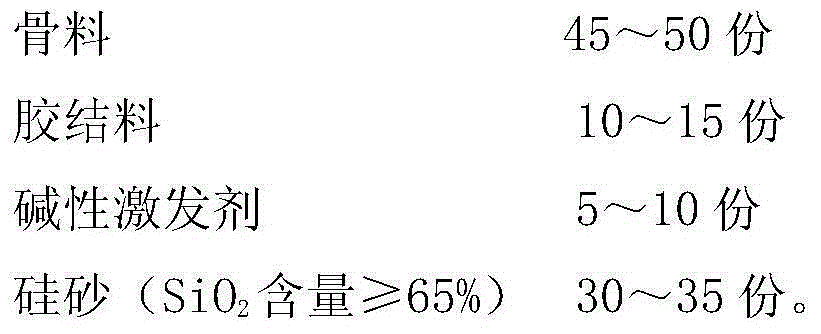

Method used

Image

Examples

preparation example Construction

[0044] Wherein, the preparation method of described building brick comprises the following steps:

[0045] a. Raw material preparation: Weigh the ingredients according to the specified weight of the building bricks; and grind the cementing material into fine powder, so that more than 95% of the fine powder particle size is ≤0.08mm; the slag after domestic waste incineration should be divided into Sorting, crushing, and grading meet the requirements for use;

[0046] b. Digestion by adding water: add water to the raw material prepared in step a, stir and mix it into a uniform wet material, and enter the digestion bin to absorb water for digestion;

[0047] c. Pressing adobe: add water and stir the wet material from the digestion bin to form a molding material, and then send it to a brick press to press into adobe;

[0048] d. Curing: The adobe obtained in step c is cured in an autoclave with saturated steam with a gauge pressure ≥ 1.5 MPa to obtain an autoclaved brick; wherein...

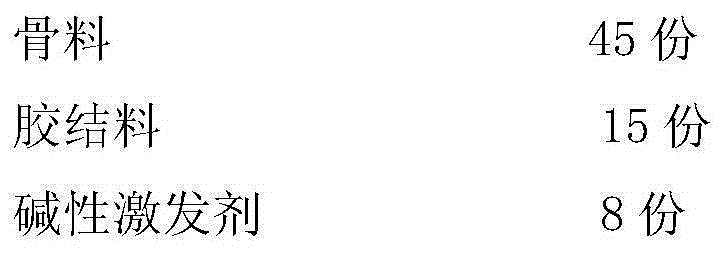

Embodiment 1

[0053] 1. Preparation of autoclaved bricks

[0054] a. Raw material preparation: According to the number 1 to 4 in Table 1, the raw materials of each component are mixed, weigh each component, and grind the cementing material into a fine powder, so that more than 95% of the fine powder has a particle size of ≤0.08mm; domestic waste The slag after incineration should be sorted, crushed and classified to meet the requirements for use;

[0055] b. Digestion by adding water: add water to the raw material prepared in step a, stir and mix it into a uniform wet material, and enter the digestion bin to absorb water for digestion;

[0056] c. Pressing adobe: add water and stir the wet material from the digestion bin to form a molding material, and then send it to a brick press to press into adobe;

[0057] d. Curing: Curing the adobe obtained in step c in an autoclave with a gauge pressure ≥ 1.5MPa of saturated steam to obtain autoclaved wall bricks or floor tiles; wherein, the satura...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com