Preparation method for atovaquone III type crystal

A technology for atovaquone and crystals, which is applied in the field of preparing atovaquone type III crystals, can solve the problem of low crystal purity of type III atovaquone, and achieve the effects of easy control of process conditions and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] At room temperature, dissolve 10.0 g of atovaquone crude product in 150 mL of acetone, then cool down to 15°C, add 0.01 g of atovaquone type III seed crystals, keep stirring for crystallization (stir for about 2 hours), and filter with suction , collected crystals, washed with 50 mL of purified water, and dried in vacuum at 45° C. to obtain 9.73 g of atovaquone type III crystals, with a mass yield of 97.3% and an HPLC purity of 98.6%.

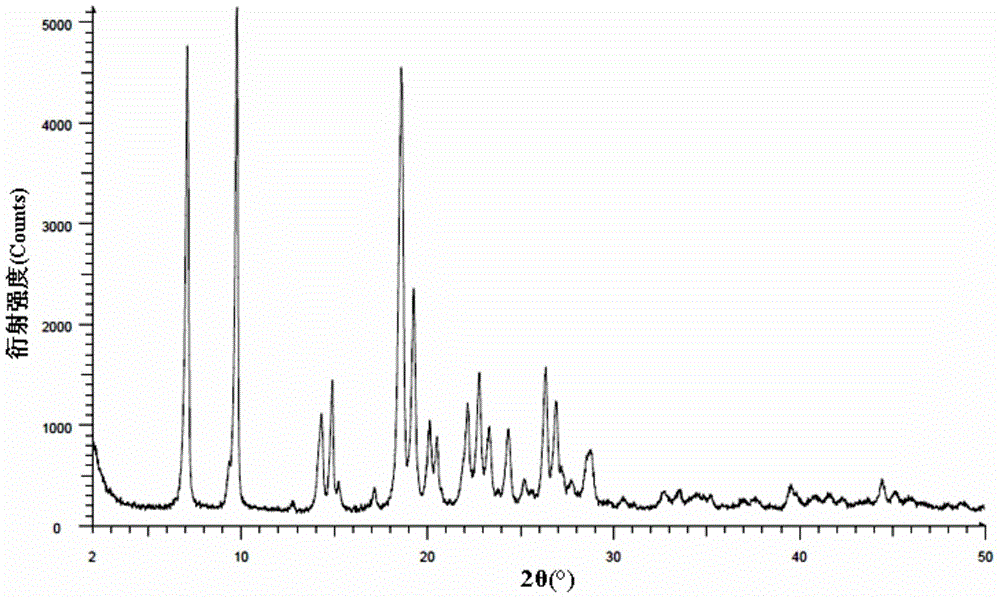

[0041] figure 1 For the X-ray powder diffraction spectrum of the obtained crystal of the present embodiment, by figure 1 It can be seen that the X-ray powder diffraction spectrum of the obtained crystal has characteristic peaks at 2θ=7.1, 9.3, 9.7, 12.8, 14.3, 14.9, 15.2, 18.7, 19.2 and 20.1°, which is the same as that reported in Chinese patent application CN1878741A The X-ray powder diffraction spectrum of atovaquone type III crystal is consistent within the error range.

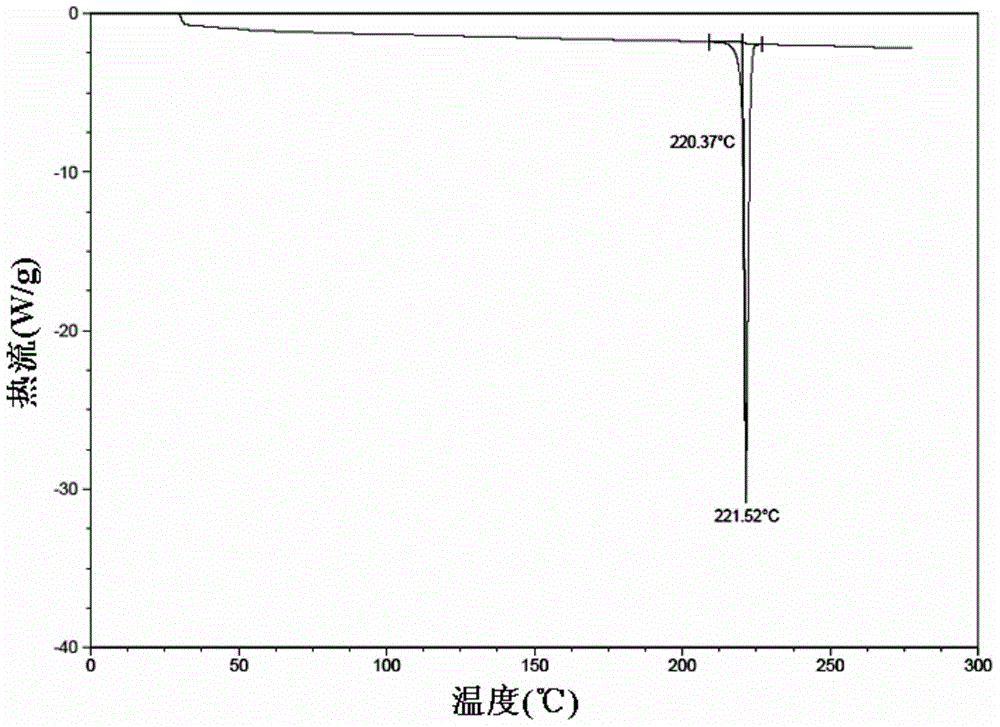

[0042] figure 2 For the DSC spectrum of the obtained crysta...

Embodiment 2

[0044] At room temperature, dissolve 5.0 g of atovaquone crude product in 50 mL of dichloromethane, then cool down to 10° C., add 0.05 g of atovaquone type III seed crystals, keep stirring to crystallize (about 0.5 hours after stirring), The crystals were collected by suction filtration, washed with 50 mL of purified water, and dried in vacuum at 50° C. to obtain 4.93 g of atovaquone type III crystals with a mass yield of 97.6% and an HPLC purity of 98.9%.

[0045] After analysis, the obtained crystals were atovaquone type III crystals.

Embodiment 3

[0047] At room temperature, dissolve 25.0 g of atovaquone crude product in 100 mL of tetrahydrofuran, then cool down to 10 ° C, add 0.25 g of atovaquone type III seed crystals, keep stirring to crystallize (about 2 hours after stirring), and filter with suction , collected crystals, washed with 50 mL of purified water, and dried in vacuum at 50° C. to obtain 24.8 g of atovaquone type III crystals, with a mass yield of 98.0% and an HPLC purity of 99.1%.

[0048] After analysis, the obtained crystals were atovaquone type III crystals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com