Flexible super capacitor and preparation method thereof

A supercapacitor and flexible technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, hybrid capacitor electrolytes, etc., can solve problems such as mutual detachment, device performance degradation, and interlayer contact deterioration, and achieve high unit area The effect of specific capacitance, simplified preparation process, and good flexibility and bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

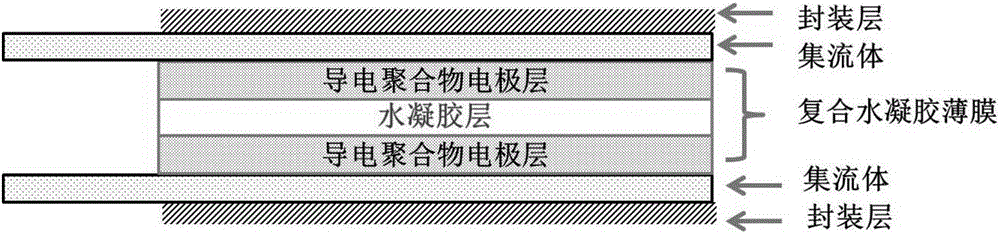

[0046] The preparation method of described flexible supercapacitor comprises the following steps:

[0047] 1) Firstly, polyvinyl alcohol is added into dilute sulfuric acid aqueous solution, and the content of polyvinyl alcohol is 5%-20%. Heat to 95° C. with stirring, and maintain the temperature until the solution becomes clear to obtain a mixed solution of polyvinyl alcohol and dilute sulfuric acid aqueous solution. After the mixed solution was cooled, 2 mL of 5% glutaraldehyde aqueous solution was added and stirred, and then the mixed solution was poured into a round watch glass, and the gelation was completed after the mixed solution lost fluidity. The film is peeled off to obtain a hydrogel electrolyte film.

[0048] 2) The hydrogel electrolyte film prepared in step 1) is placed in a solution containing a conductive polymer monomer, a dopant and an oxidizing agent, and stirred and reacted for 1-48 hours at a temperature of -10°C to 25°C to obtain Conductive polymer compo...

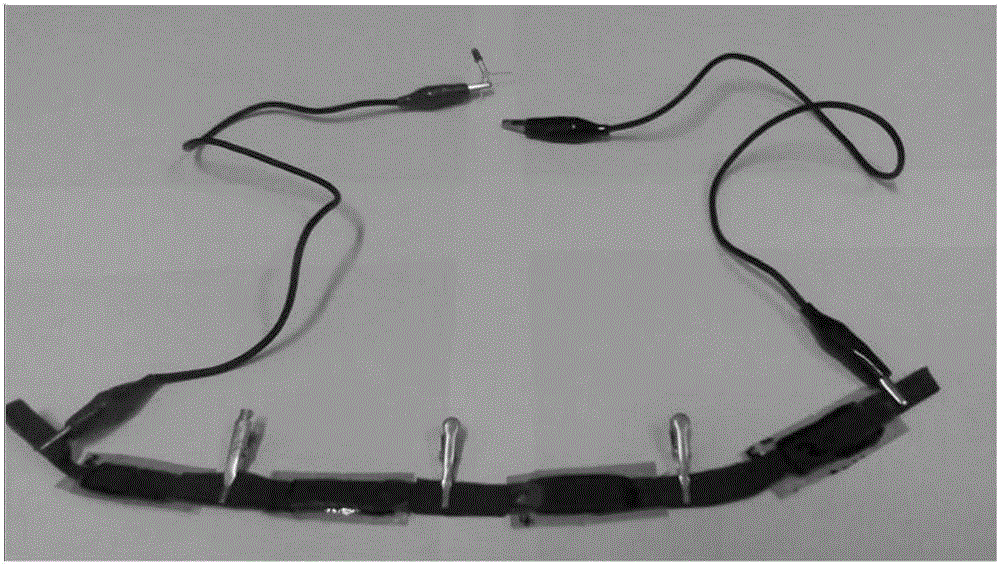

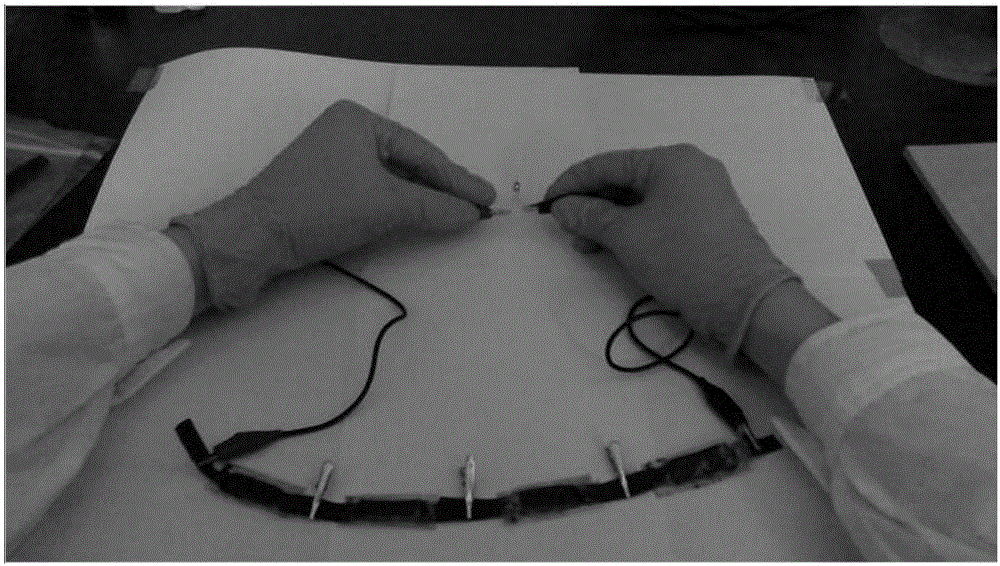

Embodiment 1

[0056] (1) Preparation of polyvinyl alcohol hydrogel film: first add 1g of polyvinyl alcohol polymer to 15mL containing 0.5molL -1 In an aqueous solution of sulfuric acid, heat to 95° C. under electromagnetic stirring and keep for 1 hour until the solution becomes clear to obtain a mixed solution of polyvinyl alcohol and aqueous sulfuric acid. Then, the above mixed solution was cooled to 5°C. Add 2ml of glutaraldehyde aqueous solution with a content of 5% volume ratio to the above mixed solution, stir for 20s, and quickly pour the mixed solution into a Φ90mm plastic round watch glass. After about 10s, the mixed solution loses its fluidity and gelation is complete. . At this time, the film can be peeled off to form a hydrogel electrolyte film. The thickness of the film was measured to be 2 mm with a thickness gauge. The appearance of the hydrogel electrolyte film is as follows Figure 2a shown.

[0057] (2) Preparation of integrated conductive polymer-polyvinyl alcohol com...

Embodiment 2

[0061] (1) Preparation of polyvinyl alcohol hydrogel film: first add 1.5g of polyvinyl alcohol polymer to 15mL containing 0.5molL -1 In an aqueous solution of sulfuric acid, heat to 95° C. under electromagnetic stirring and keep for 1 hour until the solution becomes clear to obtain a mixed solution of polymer and electrolyte solution. Then, the above solution was cooled to 1 °C. Add 2ml of glutaraldehyde aqueous solution with a content of 5% by volume to the above mixed solution and stir for 50s, and quickly pour the mixed solution into a Φ90mm round watch glass. After about 10s, the mixed solution loses fluidity and gelation is completed. The film was peeled off to form a hydrogel electrolyte film with a thickness of 2mm.

[0062] (2) Preparation of integrated conductive polymer-polyvinyl alcohol composite hydrogel with a sandwich structure: the concentration to 40mL is 1molL -1 HClO 4 Add aniline monomer ( Sinopharm Chemical Reagent Co., Ltd. production, analytically pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com