Integrated supercapacitor and preparation method thereof

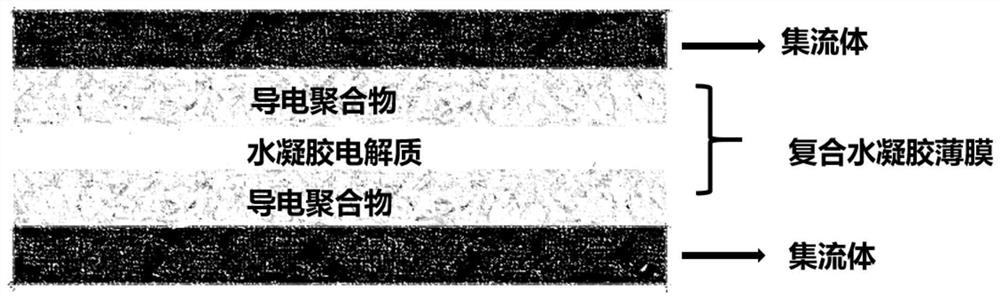

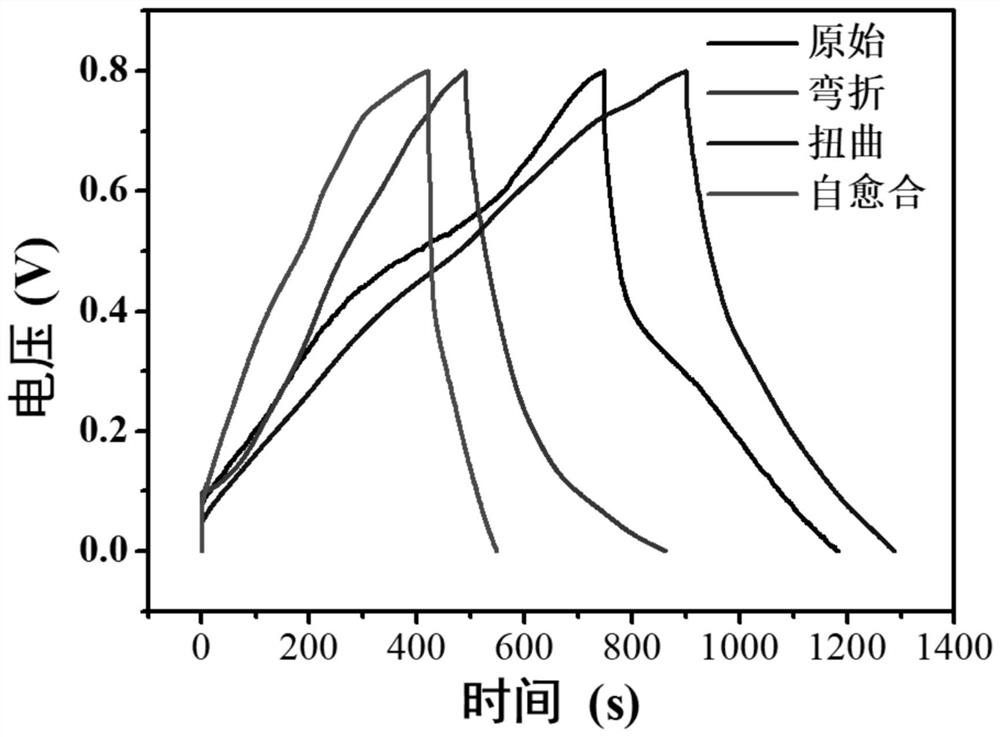

A supercapacitor, an integrated technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, hybrid capacitor electrolytes, etc., can solve the problems of easy slip between layers, poor device performance, high cost, etc., to reduce production costs , Reduce the interface resistance, the effect of high area ratio capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

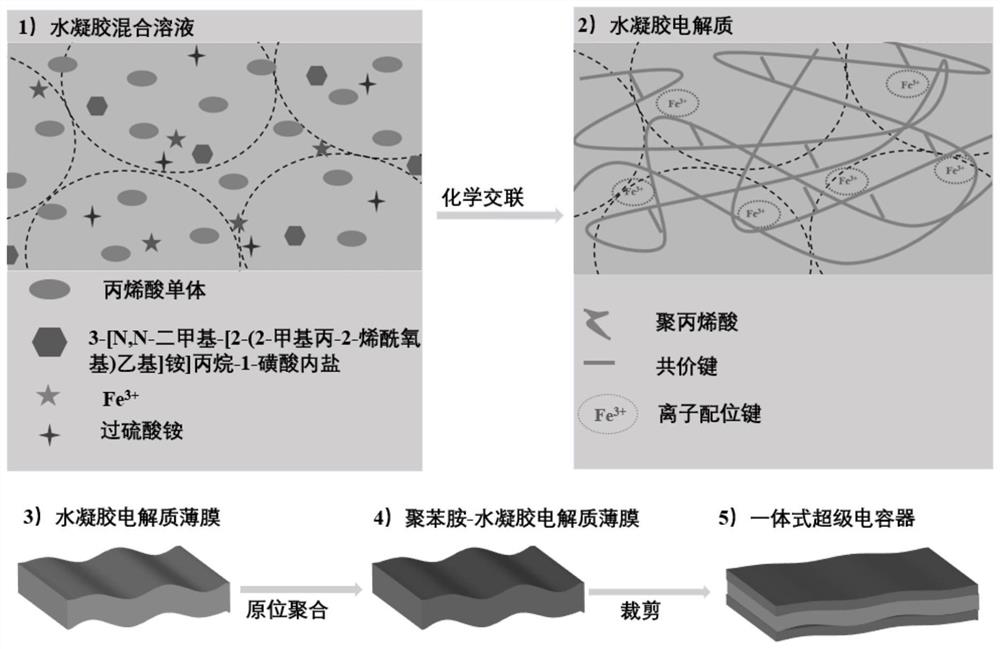

[0038] (1) Preparation of polyacrylic hydrogel electrolytic films: first 2 ml acrylic solution (99% acrylic monomer AA specification, reagent source Sigma-Aldrich) plus 3 ml of deionized water, then mixed with 0.25 g 3- [N, N-dimethyl - [2- (2-methylpropylene) ethyl] ammonium] ammonium-1-sulfonic acid salt, 0.0234 g of iron chloride and ammonium sulfate (0.0624 g) After mixing, it is injected into a well-formed glass mold, which is placed in a 40 ° C oven for 12h. After the gelation is completed, the film is taken out, forming a thick hydrogel film of 1 mm, completely drying at room temperature. The 2m sulfuric acid solution was then immersed for 15 min to obtain a polyacrylic hydrogel electrolyte film.

[0039] (2) Preparation of conductive polymer-polyacrylic water gel composite film: at 40 ml of HCl (1 mol L -1 A solution of 146 μl (0.4 mmol) of aniline monomer was added, shake it uniform, and placed in a solution of 40 * 20 mm, a thickness of 1 mm, and then added 91.2 mg (0.27...

Embodiment 2

[0043] (1) Preparation of polyacrylic hydrogel electrolytic films: first 2 ml acrylic solution (99% acrylic monomer AA specification, reagent source Sigma-Aldrich) plus 3 ml of deionized water, then mixed with 0.25 g 3- [N, N-dimethyl - [2- (2-methylpropylene) ethyl] ammonium] ammonium-1-sulfonic acid salt, 0.0234 g of iron chloride and ammonium sulfate (0.0624 g) After mixing, it is injected into a well-formed glass mold, which is placed in a 40 ° C oven for 12h. After the gelation is completed, the film is taken out, forming a thick hydrogel film of 1 mm, completely drying at room temperature. The 2m sulfuric acid solution was then immersed for 15 min to obtain a polyacrylic hydrogel electrolyte film.

[0044] (2) Preparation of conductive polymer-polyacrylic water gel film: at 40 ml of HCl (1 mol L -1 The solution was added to a solution of 219 μL (0.6 mmol) of aniline monomer, shake it uniform, and placed in a solution of 40 * 20 mm, a thickness of 1 mm, and then added 91.2 mg...

Embodiment 3

[0048] (1) Preparation of polyacrylic hydrogel electrolytic films: first 2 ml acrylic solution (99% acrylic monomer AA specification, reagent source Sigma-Aldrich) plus 3 ml of deionized water, then mixed with 0.25 g 3- [N, N-dimethyl - [2- (2-methylpropylene) ethyl] ammonium] ammonium-1-sulfonic acid salt, 0.0234 g of iron chloride and ammonium sulfate (0.0624 g) After mixing, it is injected into a well-formed glass mold, which is placed in a 40 ° C oven for 12h. After the gelation is completed, the film is taken out, forming a thick hydrogel film of 1 mm, completely drying at room temperature. The 2m sulfuric acid solution was then immersed for 15 min to obtain a polyacrylic hydrogel electrolyte film.

[0049] (2) Preparation of conductive polymer-polyacrylic water gel film: at 40 ml of HCl (1 mol L -1 The solution was added to a solution of 292 μl (0.8 mmol) of aniline monomer, shake it uniform, and placed in a solution of 40 * 20 mm, a thickness of 1 mm, and then added 91.2 mg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com