Magnetic composite nanoparticle and preparation method thereof

A magnetic composite nanometer and magnetic nanoparticle technology, applied in chemical instruments and methods, other chemical processes, alkali metal compounds, etc., can solve problems such as difficult purification of antibody proteins, and achieve mild antibody purification methods and rapid separation and purification methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

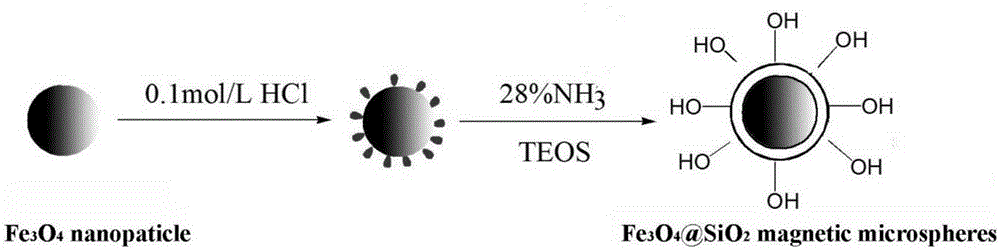

[0041] (1) Fe 3 o 4 Preparation of nanoparticles

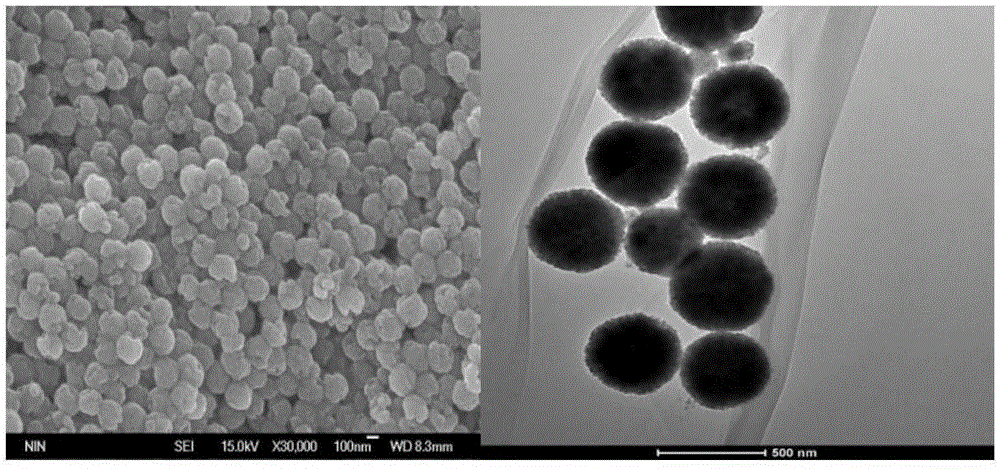

[0042] Fe with uniform size and good dispersion was prepared by hydrothermal method 3 o 4 Magnetic Nanomaterials. The general process: add an appropriate amount of FeCl to a dry and clean three-necked bottle 3 ·6H 2 O, then measure ethylene glycol and add it to a three-necked bottle as a solvent, stir mechanically until the solution is yellow and transparent, add 4.0g PEG1000, 14.4g anhydrous sodium acetate, and stir mechanically to dissolve it. Then the above solution was transferred to six 50mL Teflon-lined stainless steel reaction kettles, packaged and placed in a programmable temperature control box at 200°C for 12h, and then naturally cooled to room temperature. Pour out the magnetic fluid obtained after cooling, wash several times with ethanol after magnetic separation (magnetic separation), then wash several times with water three times (magnetic separation), and finally wash several times with absolute ethanol, a...

Embodiment 2

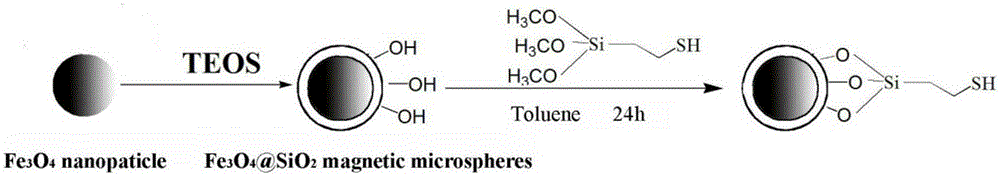

[0050] Preparation of Adsorption Media for Antibody Separation Using 3-Vinylpyridine as Ligand

[0051] with Fe 3 o 4 @SiO 2 Magnetic composite microspheres are used as the matrix, and magnetic nanoparticles with optimal particle size are selected and modified (magnetic composite microspheres of about 200nm are selected), and Fe, which has specific adsorption effect on antibodies, is prepared with MEP as the ligand. 3 o 4 @SiO 2 -MEP magnetic composite microspheres, the preparation process is as follows: First, weigh an appropriate amount of silica magnetic microspheres into a dry 100mL three-necked bottle, add 50mL of anhydrous toluene to it, and add 0.1g of 4-mercaptoethyltrimethoxy base silane, heated to 90°C, and reacted under reflux for 24h. After the reaction was completed, it was washed three times with methanol and water respectively, and then dried in an oven at 50°C for use. Then put the above product in a 100mL three-necked flask, add 50mL of anhydrous toluene...

Embodiment 3

[0054] Preparation of Adsorption Media for Antibody Separation Using 2-Vinylpyridine as Ligand

[0055] with Fe 3 o 4 @SiO 2 Magnetic composite microspheres are used as the matrix, and magnetic nanoparticles with optimal particle size are selected and modified (magnetic composite microspheres of about 200nm are selected), and Fe, which has specific adsorption effect on antibodies, is prepared with MEP as the ligand. 3 o 4 @SiO 2 -MEP magnetic composite microspheres, the preparation process is as follows: First, weigh an appropriate amount of silica magnetic microspheres into a dry 100mL three-necked bottle, add 50mL of anhydrous toluene to it, and add 0.1g of 4-mercaptoethyltrimethoxy base silane, heated to 90°C, and reacted under reflux for 24h. After the reaction was completed, it was washed three times with methanol and water respectively, and then dried in an oven at 50°C for use. Then put the above product in a 100mL three-necked flask, add 50mL of anhydrous toluene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com