Method for preventing air from entering molten steel through water gap during steel making and casting

A nozzle and molten steel technology, which is applied to casting equipment, casting melt containers, manufacturing tools, etc., can solve problems such as blockage, achieve simple process operation, easy raw materials, and improve continuous casting efficiency and product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

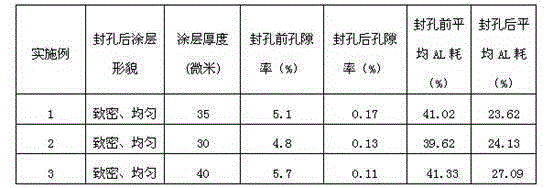

Embodiment 1

[0019] The sealing agent used in the first layer is nano-scale SiO 2 +H 2 O sol, SiO 2 The concentration is 5%, the nozzle is immersed in SiO 2 +H 2 In the O sol solution, one end of the nozzle is sealed, the other end is connected to a vacuum pump, and the vacuum is operated for 3 minutes to make the vacuum in the nozzle reach 0.95MPa, and the negative pressure generated by the vacuum is used to make the SiO 2 +H 2 O sol solution immerses into the inside of the pipe wall through the pores on the outer wall of the nozzle, so that the SiO in the solution 2 The particles play the role of sealing holes; after the nozzle is taken out, rinse the inner wall of the nozzle with water to wash away the solution residue; the nozzle is cured at 100°C for 8 hours; the second layer of PbO+SiO is treated by brushing process 2 +B 2 o 3 +H 2 O sealing agent, PbO, SiO 2 , B 2 o 3 , and H 2 The mass ratio of O is 2:38:28:32 respectively; after that, the nozzle is heat-treated at 900°...

Embodiment 2

[0021] The sealing agent used in the first layer is nano-scale SiO 2 +H 2 O sol, SiO 2 The concentration is 8%, the nozzle is immersed in SiO 2 +H 2 In the O sol solution, one end of the nozzle is sealed, the other end is connected to a vacuum pump, and the vacuum is operated for 5 minutes to make the vacuum degree in the nozzle reach 0.98MPa, and the negative pressure generated by vacuuming is used to make the sol solution immerse into the inside of the pipe wall through the channel on the outer wall of the nozzle, SiO in solution 2 The particles play the role of sealing holes; after the nozzle is taken out, the inner wall of the nozzle is washed with water to wash away the solution residue; after that, the nozzle is cured at 150°C for 6 hours; the second layer of PbO+SiO is treated by spraying process 2 +B 2 o 3 +H 2 O sealing agent, PbO, SiO 2 , B 2 o 3 , and H 2 The mass ratio of O is 2:40:27:31 respectively; after that, the nozzle is heat-treated at 1000°C for ...

Embodiment 3

[0023] The sealing agent used in the first layer is nano-scale SiO 2 +H 2 O sol, the concentration of SiO2 is 10%, and the nozzle is immersed in SiO 2 +H 2 In the O sol solution, one end of the nozzle is sealed, the other end is connected to a vacuum pump, and the vacuum operation is performed for 8 minutes to make the vacuum degree in the nozzle reach 1MPa. The negative pressure generated by vacuuming is used to make the sol solution immerse into the inside of the pipe wall through the hole on the outer wall of the nozzle, so that SiO in solution 2 The particles play the role of sealing holes; after the nozzle is taken out, the inner wall of the nozzle is washed with water to wash away the solution residue; after that, the nozzle is cured at 200°C for 5 hours; the second layer of PbO+SiO is treated by spraying process 2 +B 2o 3 +H 2 O sealing agent, PbO, SiO 2 , B 2 o 3 , and H 2 The mass ratio of O is 2:43:31:36; the nozzle is heat-treated at 1100°C for 1 hour to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com