Low-temperature co-fired ceramic material and preparation method thereof

A technology of low-temperature co-fired ceramics and ceramics, which is applied in the field of low-temperature co-fired ceramic materials and their preparation, high-frequency low-dielectric loss low-temperature co-fired ceramic materials and their preparation fields, and can solve the problems of poor device stability, large property changes, and process problems. Narrow windows and other issues, to achieve excellent dielectric properties, low dielectric loss, and reduce the effect of sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

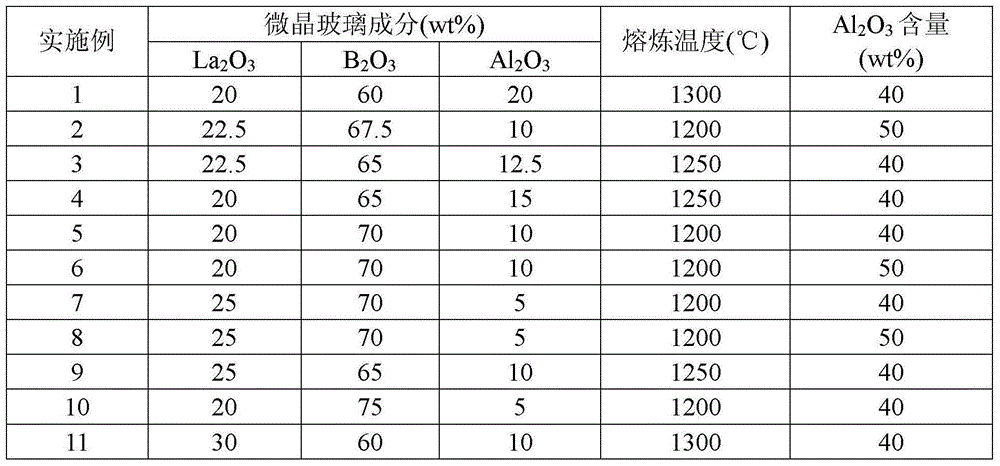

Examples

Embodiment 1

[0033] A kind of low-temperature co-fired ceramic material of the present invention, this low-temperature co-fired ceramic material is made of La 2 o 3 -B 2 o 3 -Al 2 o 3 Glass-ceramic and Al 2 o 3 Ceramic filling phase composition, wherein, by mass fraction, the La 2 o 3 -B 2 o 3 -Al 2 o 3 glass-ceramic is 60wt%, the Al 2 o 3 The ceramic filling phase is 40 wt%.

[0034] In this example, La 2 o 3 -B 2 o 3 -Al 2 o 3 The mass fraction of each component in the glass-ceramic is: La 2 o 3 20wt%, B 2 o 3 60wt%, Al 2 o 3 is 20wt%.

[0035] In this embodiment, the dielectric constant of the low temperature co-fired ceramic material is 7.85, and the dielectric loss is 4.21×10 -3 , the frequency is 8.65GHz.

[0036] A preparation method of the above-mentioned low temperature co-fired ceramic material of the present embodiment, comprising the following steps:

[0037] (1)La 2 o 3 -B 2 o 3 -Al 2 o 3 Preparation of glass-ceramic powder: 20wt% lanthanum o...

Embodiment 2

[0043] A low temperature co-fired ceramic material of the present invention, comprising 50wt% La 2 o 3 -B 2 o 3 -Al 2 o 3 Glass-ceramic and 50wt% Al 2 o 3 Ceramic filler phase.

[0044] In this example, La 2 o 3 -B 2 o 3 -Al 2 o 3 The mass fraction of each component in the glass-ceramic is: La 2 o 3 22.5wt%, B 2 o 3 67.5wt%, Al 2 o 3 is 10wt%.

[0045] In this embodiment, the dielectric constant of the low temperature co-fired ceramic material is 7.69, and the dielectric loss is 3.24×10 -3 , the frequency is 8.84GHz.

[0046] Concrete operation steps and process parameter of embodiment 2 are basically the same as embodiment 1, and difference is:

[0047] The heat preservation melting temperature in the step (1) is 1200°C.

[0048] The sintering temperature in step (5) is 900°C.

Embodiment 3

[0050] A low temperature co-fired ceramic material of the present invention, comprising 60wt% La 2 o 3 -B 2 o 3 -Al 2 o 3 Glass-ceramic and 40wt% Al 2 o 3 Ceramic filler phase.

[0051] In this example, La 2 o 3 -B 2 o 3 -Al 2 o 3 The mass fraction of each component in the glass-ceramic is: La 2 o 3 22.5wt%, B 2 o 3 65wt%, Al 2 o 3 It is 12.5wt%.

[0052] In this embodiment, the dielectric constant of the low temperature co-fired ceramic material is 7.54, and the dielectric loss is 3.68×10 -3 , the frequency is 8.51GHz.

[0053] Concrete operation steps and process parameter of embodiment 3 are substantially the same as embodiment 1, and difference is:

[0054]The heat preservation melting temperature in the step (1) is 1250°C.

[0055] The sintering temperature in step (5) is 900° C., and the holding time is 1 h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Frequency | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com