Concrete containing ether ester type water reducing agent, and preparation method thereof

A technology of water reducing agent and concrete, which is applied in the field of concrete containing ether ester type water reducing agent and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

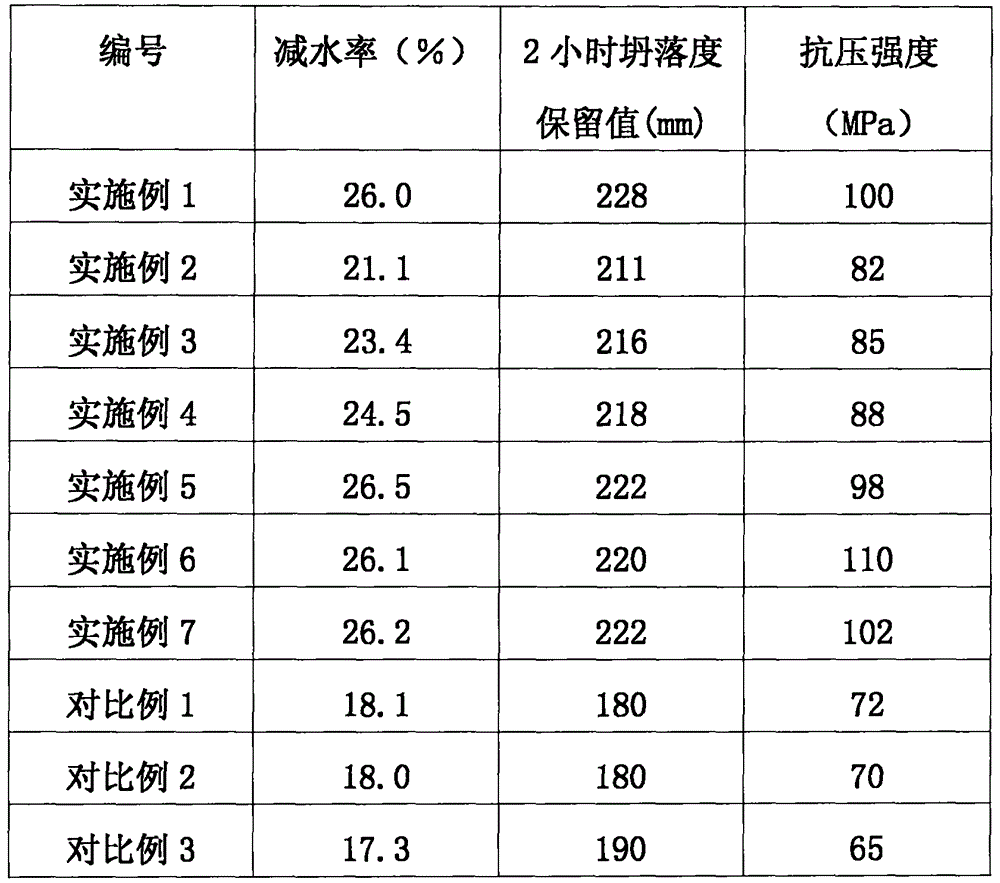

Examples

preparation Embodiment 1

[0025] 1. Prepare base material

[0026] Add 145 kg of isobutenyl polyethylene glycol and 6 kg of acrylic acid to 120 kg of deionized water, stir and mix evenly to prepare a mixture, the mixture is warmed up to 20°C, and then 800 grams of 27.5% hydrogen peroxide and ammonium persulfate are added to the mixture 80 grams, stirred and mixed to prepare the bottom material.

[0027] 2. Preparation of A drip feed

[0028] A drop feed was prepared by adding 0.4 kg of vitamin C and 0.48 kg of mercaptopropionic acid (chain transfer agent) to 40 kg of deionized water.

[0029] 3. Preparation of modified polyethylene glycol methacrylate

[0030] Add 800 grams of polyethylene glycol monomethyl ether (molecular weight is 1200) into anhydrous drying kettle, stir and mix evenly, add 0.53 grams of phenothiazine, 232 grams of methacrylic acid and 21.3 grams of p-toluenesulfonic acid, seal and heat up to 120 ℃, esterification for 6.5 hours, during the 6.5 hours of esterification, the first v...

preparation Embodiment 2

[0036] Other conditions are the same as in Example 1 of the preparation of water reducer, except that polyethylene glycol acrylate is prepared in step 3 instead of modified polyethylene glycol acrylate, wherein the preparation step of polyethylene glycol acrylate include:

[0037] Add 800 grams of polyethylene glycol monomethyl ether (molecular weight: 1200) into an anhydrous drying kettle, stir and mix evenly, add 0.45 grams of phenothiazine, 232 grams of methacrylic acid, seal and heat up to 100 ° C, esterify for 6.5 hours, During the 6.5-hour esterification process, vacuuming was performed for the first time at the 2nd hour, and then reacted for 1 hour and 45 minutes. The second time was vacuumed, and the reaction was continued for 1 hour. Add the vacuumized waste liquid to obtain polyethylene glycol methacrylate.

preparation Embodiment 3

[0039] Other conditions were the same as those in Example 1 of the preparation of the water reducer, except that in Step 3, 194 grams of acrylic acid was used instead of 232 grams of methacrylic acid to obtain modified polyethylene glycol acrylate accordingly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com