Alkynyl-terminated curing agent and preparation method thereof

A curing agent, terminal alkynyl technology, applied in chemical instruments and methods, preparation of organic compounds, preparation of carbamate derivatives, etc., can solve the problems affecting mechanical properties, the decrease of propellant safety and reliability, and the decrease of propellant density and other problems, to achieve the effect of improving mechanical strength, increasing elongation, and promoting microphase separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

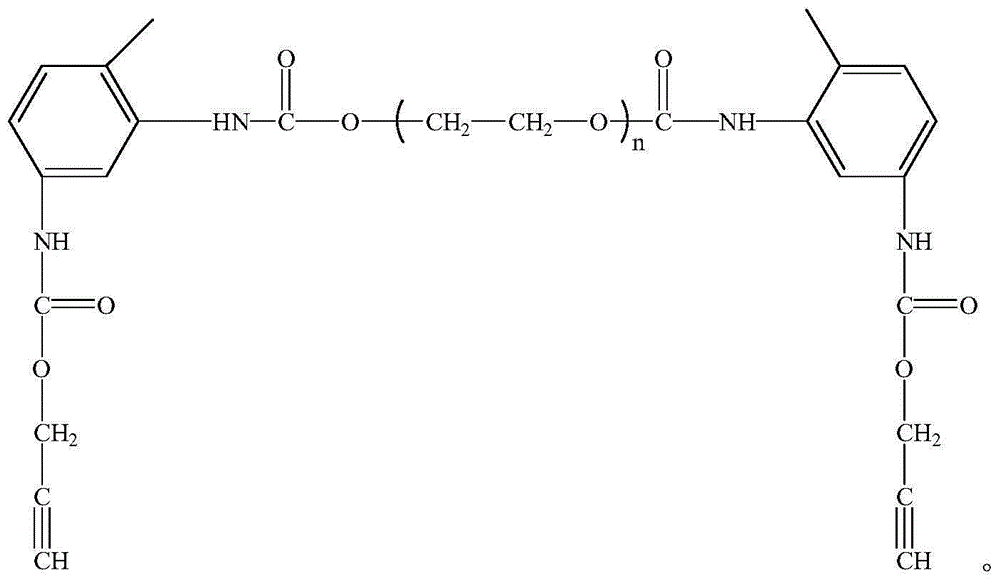

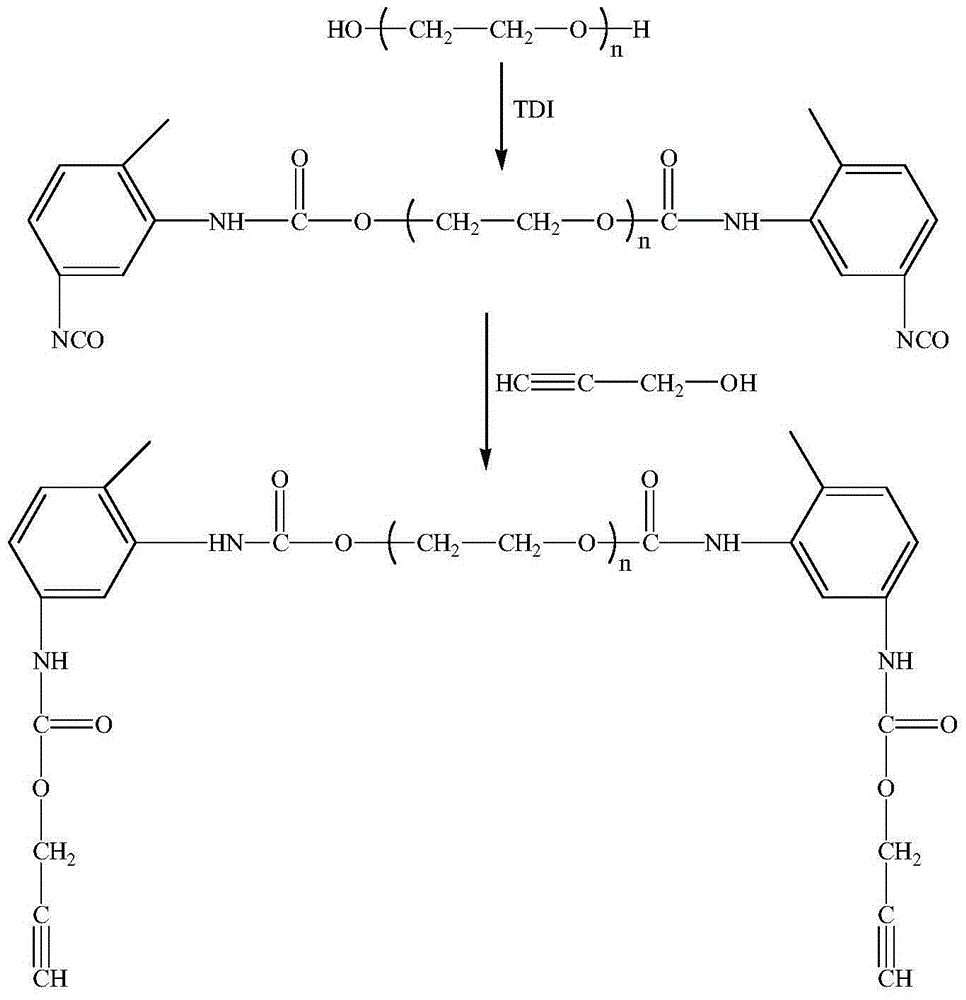

[0026] Add 200ml tetrahydrofuran, 100g (0.25mol) PEG400 and 7.4ml (0.0125mol) dibutyltin dilaurate successively in a 500ml four-neck round bottom flask equipped with mechanical stirring, reflux condenser, thermometer, and dropping funnel, and stir evenly , heated to 40°C, then added 87.08g (0.5mol) of TDI, and reacted at 43°C to 45°C for 6h. Then, 29.4 g (0.525 mol) of propynyl alcohol was added dropwise to the above reaction system, and reacted at 80° C. to 82° C. for 8 hours after the dropwise addition was completed. Cooled to room temperature, extracted with saturated brine, and the upper layer liquid was rotary evaporated and vacuum dried to obtain 193.7 g of a light yellow transparent viscous liquid with a yield of 90.1%.

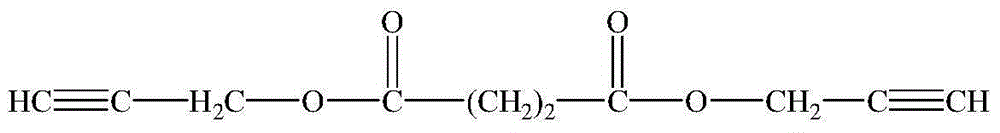

[0027] Structure Identification: Infrared (KBr, cm -1 ): 3309 (≡C-H), 3067 (C-H on the benzene ring), 2965 (-CH 3 ),2846(-CH 2 ), 2110(C≡C), 1728(C=O), 1107~1115(C-O-C).

[0028] The theoretical number average molecular weight is 860, and the measu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com