Cooling wall of blast furnace and manufacturing method of cooling wall

A manufacturing method and cooling stave technology, applied to cooling devices, etc., can solve problems such as poor mechanical properties of copper staves, copper stave damage, open welding of water pipes, etc., and achieve good cooling effect, strong cooling capacity, and good thermal conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

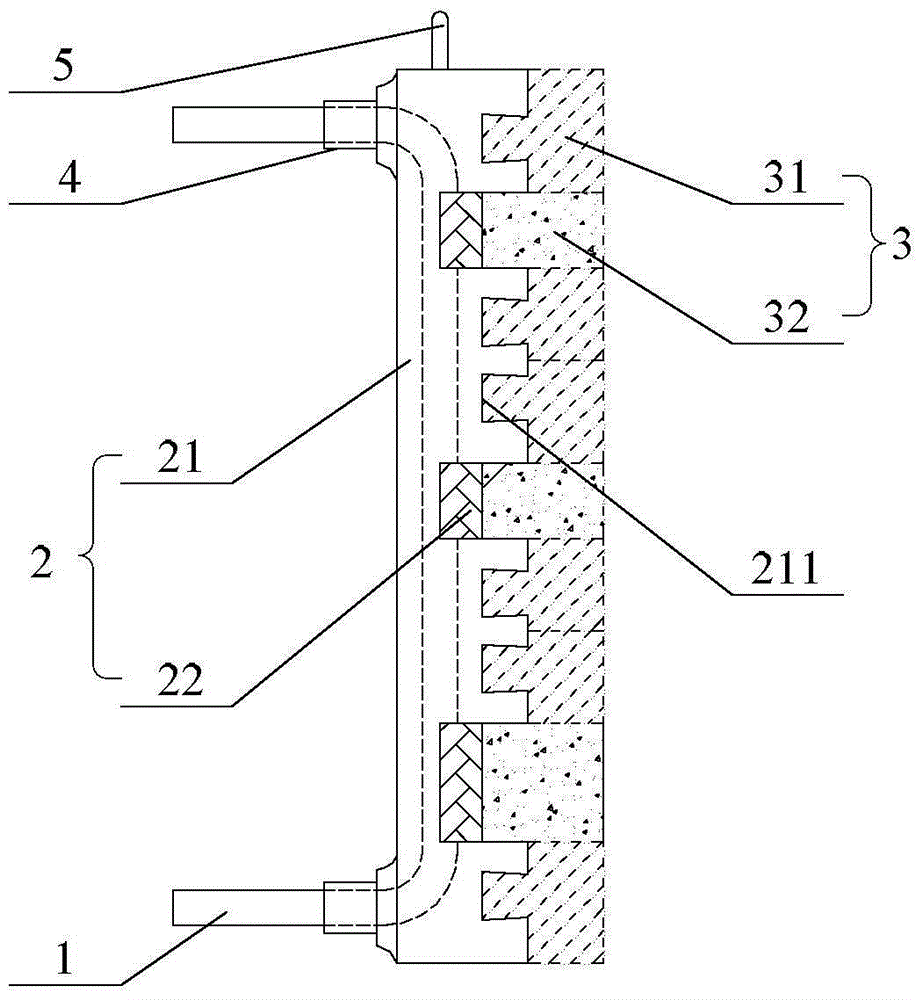

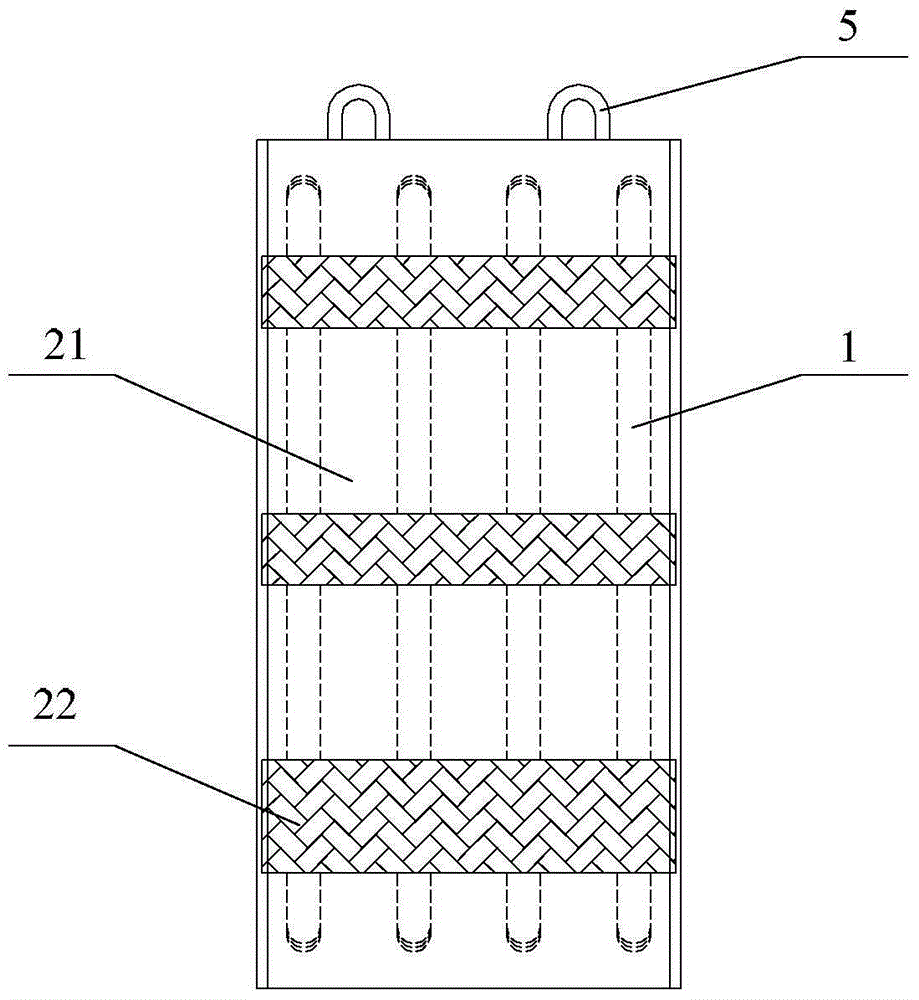

[0031] In order to have a clearer understanding of the technical solutions, objectives and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

[0032] It should be noted that, in figure 1 and figure 2 In order to clearly show the connection relationship between each cooling pipe and the cast steel heat conductor and copper heat conductor, each cooling pipe is drawn with a dotted line.

[0033] Such as figure 1 and figure 2 As shown, the present invention provides a cooling stave of a blast furnace, which includes: a plurality of cooling pipes 1 arranged vertically side by side and a body 2 coated on the outside of the plurality of cooling pipes 1, the liquid inlet end of each cooling pipe 1 and The liquid outlets extend out of the main body 2. The main body 2 is composed of a cast steel heat conductor 21 and a copper heat conductor. The cast steel heat conductor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com