Device and method for preparing potassium sulphate

A potassium sulfate and sampling device technology, which is applied in cells, electrolysis process, electrolysis components, etc., can solve the problems of corrosiveness, complex process flow, and large turnover of mother liquor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

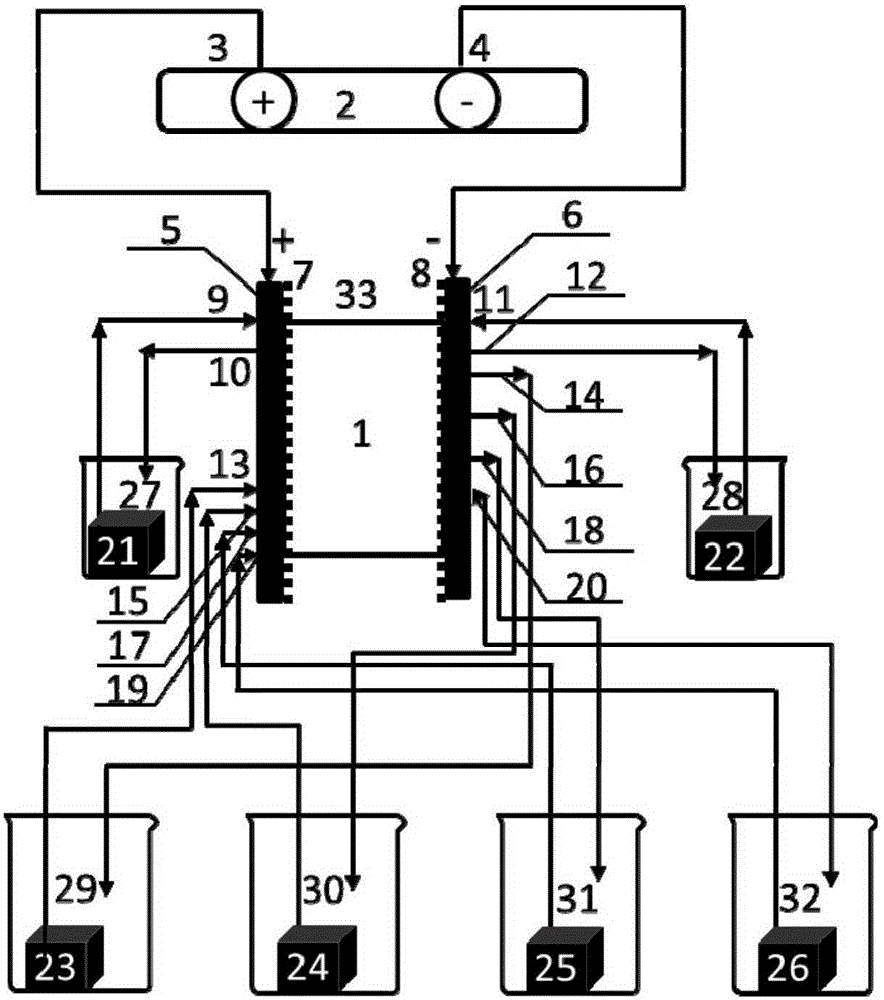

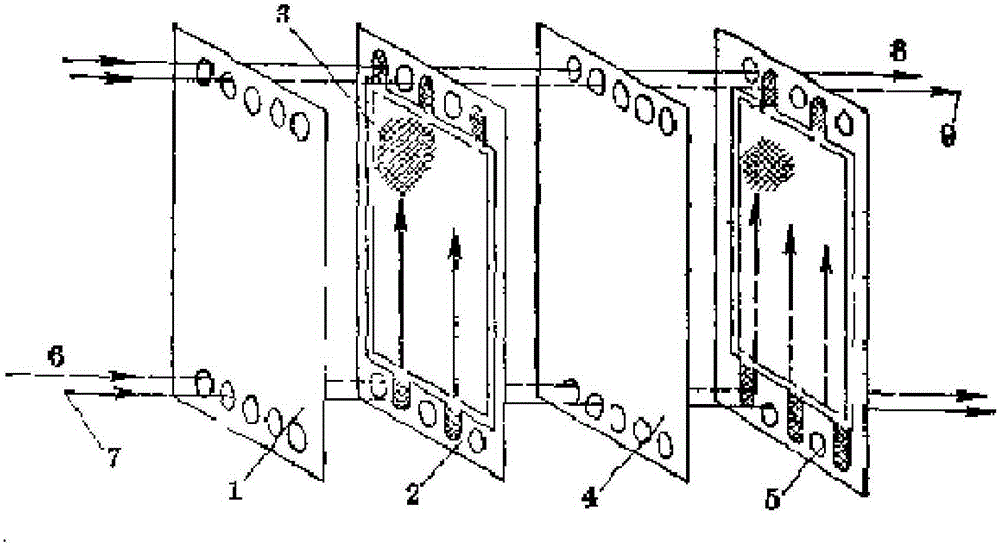

[0120] Assembling the device: Specifically, the electrodialysis device 33 is composed of anion exchange membranes and cation exchange membranes alternately laminated, plus auxiliary materials such as flow channel separators and gaskets, and consists of 22 pairs of anion exchange membranes and cation exchange membranes. The membrane stack 1, the effective area of each membrane is 200dm 2 , and the cathode and anode electrodes 8 and 7 respectively arranged at both ends of the membrane stack, and the electrodialysis device 33 formed by clamping the clamping devices 5 and 6 arranged at the two ends of the electrodes through bolt clamping, the anode chamber inlet 9, the outlet 10, and the cathode chamber inlet 11. Outlet 12, first salt chamber tank inlet 13, outlet 14, second salt chamber tank inlet 15, outlet 16, third salt chamber tank inlet 17, outlet 18, fourth salt chamber tank inlet 19, outlet 20 respectively through The latex tube is connected to the inside of the correspo...

Embodiment 2

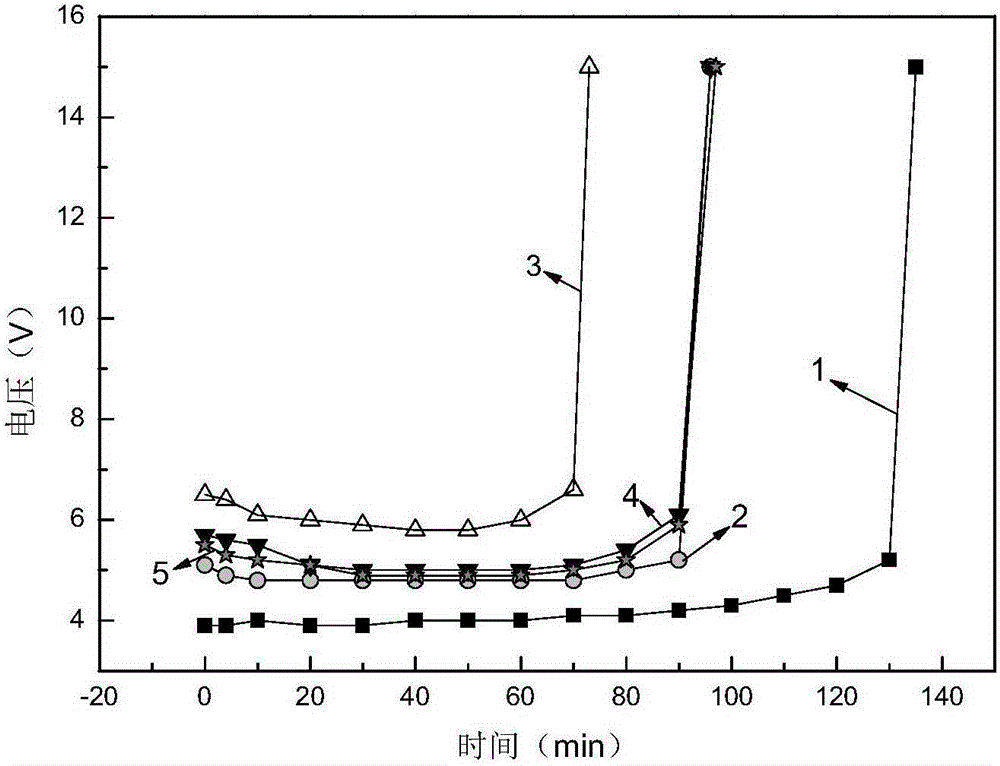

[0132] Adopt the device for preparing potassium sulfate shown in embodiment 1 to prepare potassium sulfate, comprise the following steps:

[0133] Perfusion 200mL molar concentration is the potassium sulfate solution of 0.4mol / L in the anode chamber tank 27 and the cathode chamber tank 28 respectively; The volume of potassium sulfate solution accounts for 40% of the volume of the cathode chamber tank 28 .

[0134] Into the first salt room tank 29, pour 250 mL of potassium chloride solution with a molar concentration of 2.8 mol / L, and the volume of the potassium chloride solution accounts for 50% of the first salt room tank 29 volume.

[0135] Into the second salt room tank 30, pour 250 mL of ammonium sulfate solution with a molar concentration of 2.8 mol / L, and the volume of the ammonium sulfate solution accounts for 50% of the volume of the second salt room tank 30 .

[0136] Inject 700 mL of potassium sulfate solution with a molar concentration of 0.05 mol / L into the third ...

Embodiment 3

[0143] Adopt the device for preparing potassium sulfate shown in embodiment 1 to prepare potassium sulfate, comprise the following steps:

[0144] Perfusion 300mL molar concentration is the potassium sulfate solution of 0.3mol / L in the anode chamber tank 27 and the cathode chamber tank 28 respectively; The volume of potassium sulfate solution accounts for 50% of the volume of the cathode chamber tank 28 .

[0145] Into the first salt room tank 29, pour 250 mL of potassium chloride solution with a molar concentration of 2.8 mol / L, and the volume of the potassium chloride solution accounts for 50% of the first salt room tank 29 volume.

[0146] Into the second salt room tank 30, pour 200 mL of ammonium sulfate solution with a molar concentration of 2.8 mol / L, and the volume of the ammonium sulfate solution accounts for 40% of the volume of the second salt room tank 30 .

[0147] Inject 700 mL of potassium sulfate solution with a molar concentration of 0.05 mol / L into the third ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com