Automatic biomass particle heating stove and ignition method thereof

A biomass pellet and heating stove technology, which is applied in heating methods, household stoves/stoves, stoves/stoves with hot water devices, etc., can solve the problems of indoor environmental impact, low ignition success rate, and black smoke generation. Achieve the effect of ensuring combustion adequacy, reducing atmospheric emissions, and automatically adjusting air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] In order to facilitate the understanding of the technical content of the present invention, the technical solutions thereof will be further described below in conjunction with the accompanying drawings.

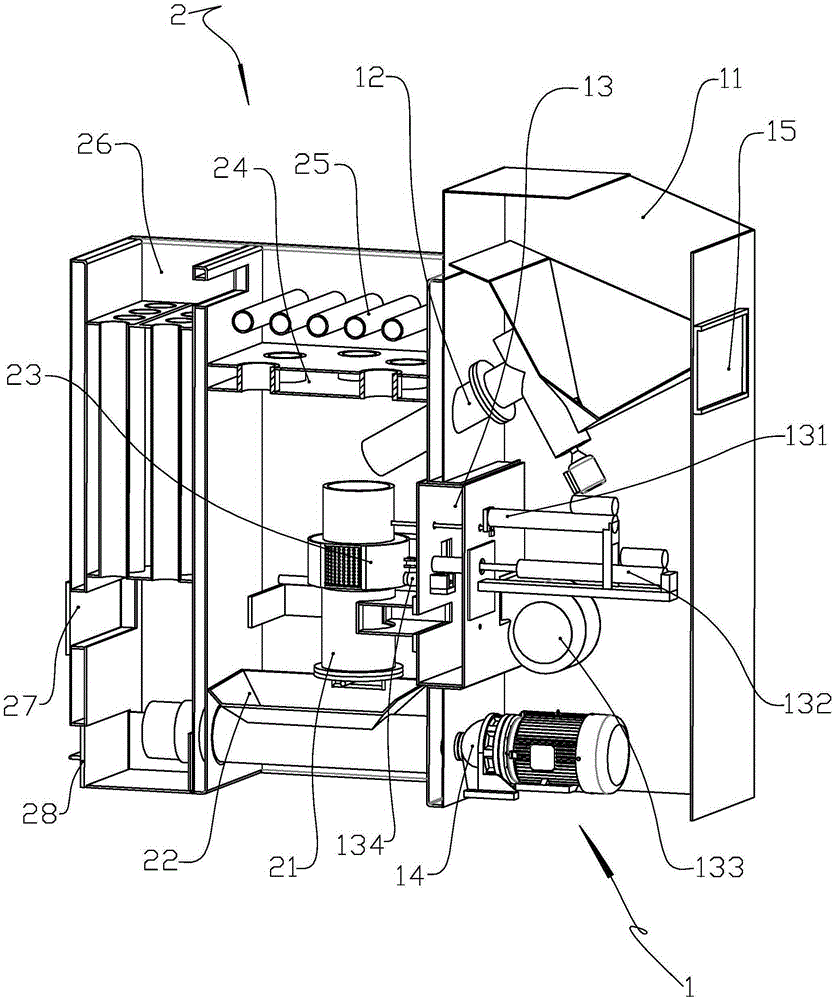

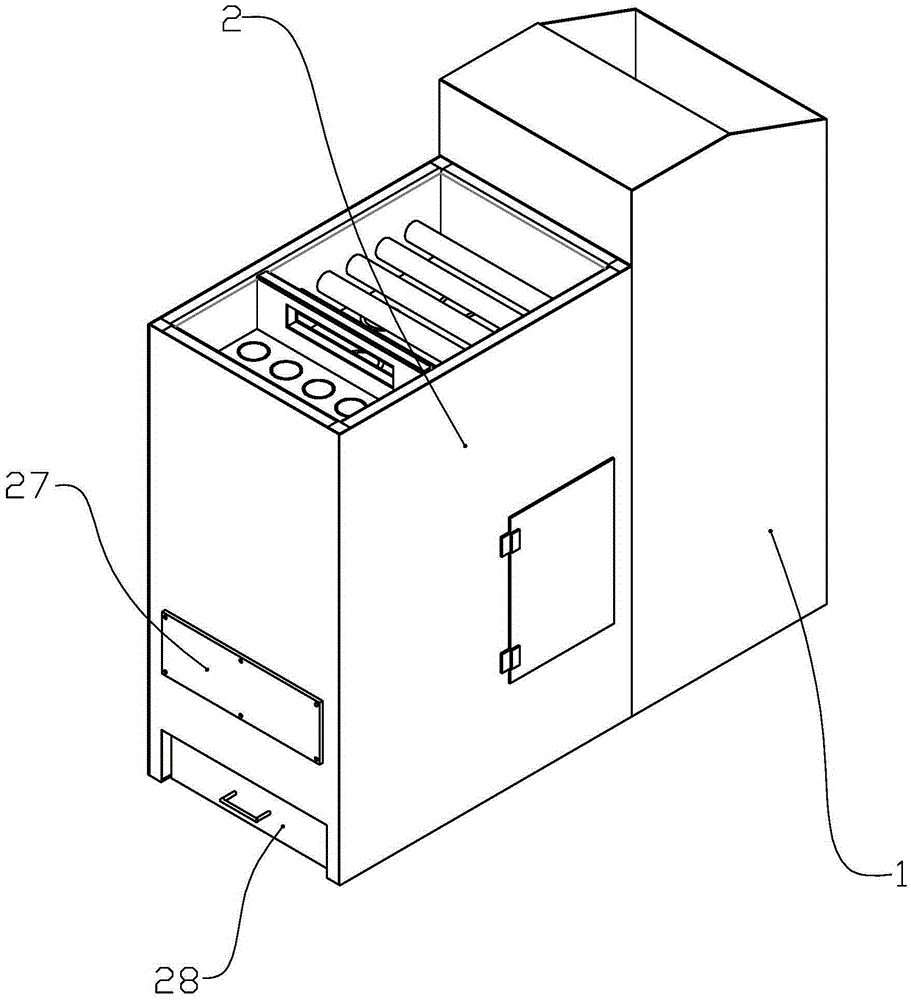

[0058] Such as figure 1 , figure 2 A biomass particle automatic heating furnace shown includes a control box 1 and a furnace box 2 connected to the left side of the control box 1 .

[0059] The upper cavity of the control box 1 is set as a granule bin 11, and the lower end of the granule bin 11 is funnel-shaped. A feeding auger device is arranged on the left side outer wall of the funnel-shaped part at the lower end of the particle bin 11, so that the axial direction of the auger feeding cylinder in the feeding auger device is arranged obliquely upward. And the feeding tube 12 is set on the upper end of the auger feeding tube, the feeding tube 12 is axially inclined downward, and one end passes through the partition between the control box 1 and the furnace box 2 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com