Automatic shell removing and muscle fetching machine for scallops

An automatic and meat machine technology, applied in bivalves processing, etc., can solve problems such as simple and rough evisceration, secondary pollution of scallops, and affecting product perception

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

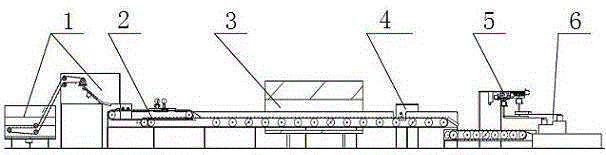

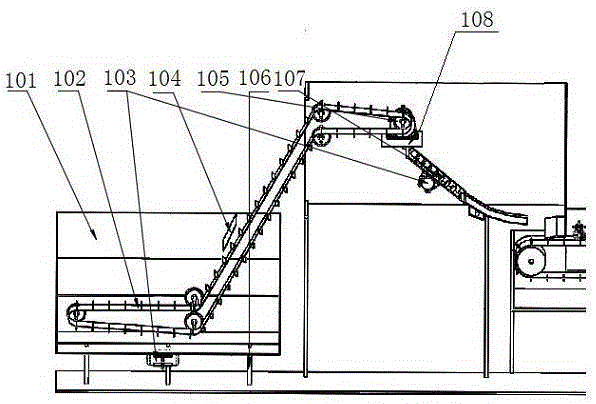

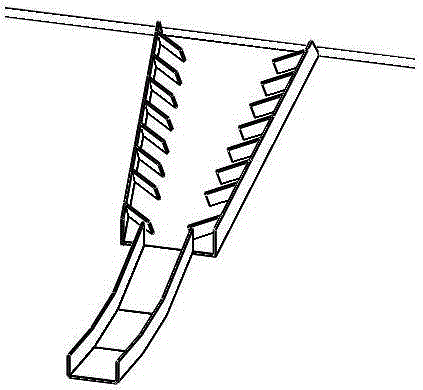

[0020] Such as Figure 1 to Figure 10 As shown, the scallop automatic shelling and meat extraction machine includes an extraction device 1, a sorting device 2, a heating box 3, a shell removing device 4, a meat removal device 5 and a collection device 6 connected in sequence, and the extraction device includes a feed box 101 , conveyor belt 102, vibrating motor 103, the first blocking plate 104, the first AC motor 105, spring 106 and funnel-shaped chute 107, the conveyor belt 102 is connected with the feed box 101, and the vibrating motor 103 is installed on a part of the feed box casing side, the first blocking plate 104 is arranged above the conveyor belt 102, the spring 106 is installed at the bottom of the vibration motor 103, the funnel-shaped chute 107 is installed at the end of the conveyor belt 102, and the sorting device 2 includes a second blocking plate 201, a brush 202, a stroke Switch 203, the second AC motor 204 and baffle plate 205, the second blocking plate 201...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com