A kind of enrofloxacin injection and preparation method thereof

A technology for enrofloxacin and injection, applied in the field of enrofloxacin injection and its preparation, can solve the problems of high irritation, low concentration, multiple administration and the like, and achieve the effects of promoting dissolution and lowering pH value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

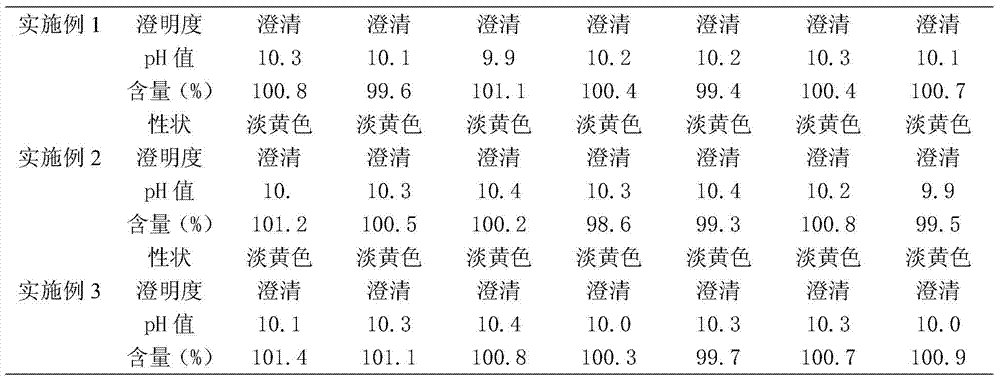

Examples

Embodiment 1

[0013] Every 100ml of enrofloxacin injection is prepared through the following steps:

[0014] 1) Take by weighing 20g sodium hydroxide and dissolve in 100ml water for injection to form 20% sodium hydroxide solution, set aside;

[0015] 2) Weigh 20g of meglumine and 20ml of polyethylene glycol 400, respectively dissolve them in 70ml of water for injection at 80°C, and completely dissolve to obtain a mixed solvent;

[0016] 3) Weigh 20g of enrofloxacin and add it into the mixed solvent, stir and dissolve;

[0017] 4) Add 20% sodium hydroxide solution dropwise until clear, stir evenly, make up 100ml of water for injection, and adjust the pH value to 9.5-10.5;

[0018] 5) Coarse filtration, fine filtration, filling with nitrogen, autoclaving at 121°C for 20 minutes, light inspection, and packaging.

Embodiment 2

[0020] Every 100ml of enrofloxacin injection is prepared through the following steps:

[0021] 1) Take by weighing 20g sodium hydroxide and dissolve in 100ml water for injection to form 20% sodium hydroxide solution, set aside;

[0022] 2) Weigh 15g of meglumine and 15ml of polyethylene glycol 400, respectively dissolve them in 70ml of water for injection at 80°C, and completely dissolve to obtain a mixed solvent;

[0023] 3) Weigh 15g of enrofloxacin and add it into the mixed solvent, stir and dissolve;

[0024] 4) Add 20% sodium hydroxide solution dropwise until clarification, adjust the pH value to 9.5-10.5, stir well, and make up 100ml of water for injection;

[0025] 5) Coarse filtration, fine filtration, filling with nitrogen, autoclaving at 121°C for 20 minutes, light inspection, and packaging.

Embodiment 3

[0027] Every 100ml of enrofloxacin injection is prepared through the following steps:

[0028] 1) Take by weighing 20g sodium hydroxide and dissolve in 100ml water for injection to form 20% sodium hydroxide solution, set aside;

[0029] 2) Weigh 10g of meglumine and 10ml of polyethylene glycol 400, respectively dissolve them in 70ml of water for injection at 80°C, and completely dissolve to obtain a mixed solvent;

[0030] 3) Weigh 10g of enrofloxacin and add it into the mixed solvent, stir to dissolve;

[0031] 4) Add 20% sodium hydroxide solution dropwise until clarification, adjust the pH value to 9.5-10.5, stir well, and make up 100ml of water for injection;

[0032] 5) Coarse filtration, fine filtration, filling with nitrogen, autoclaving at 121°C for 20 minutes, light inspection, and packaging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com