Method for synthesizing lamella g-C3N4 and TiO2 nanorod composite material through assistance of ultrasonic wave

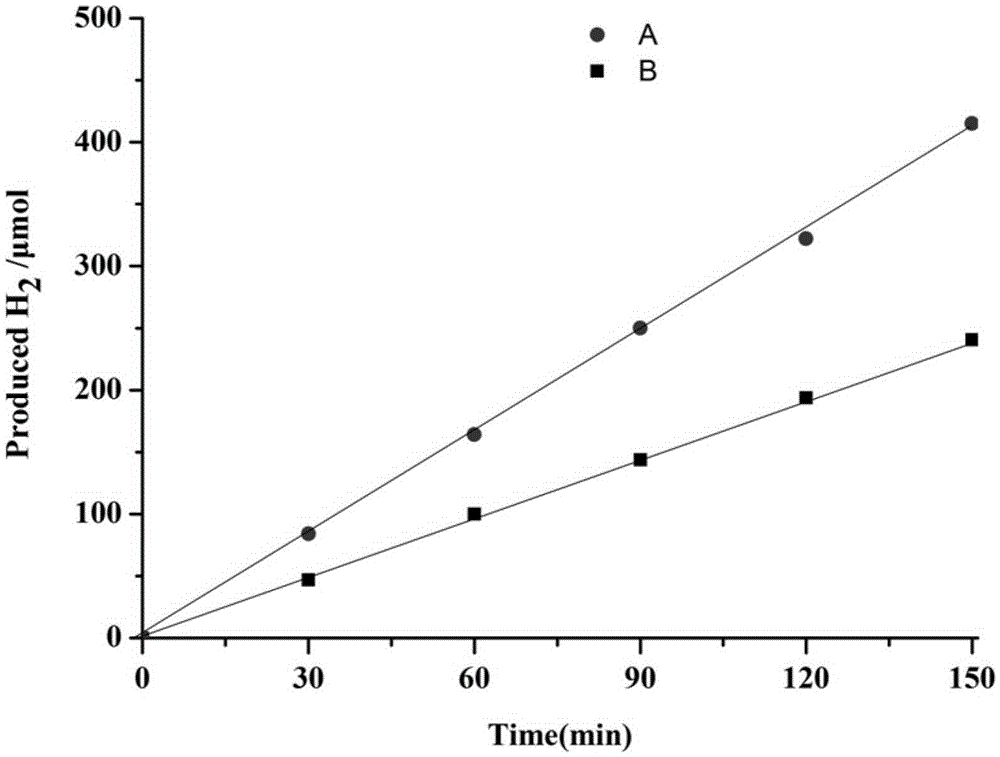

An ultrasonic-assisted, composite material technology, applied in chemical instruments and methods, hydrogen production, catalysts for physical/chemical processes, etc., can solve problems such as difficult peeling, and achieve the effects of cheap raw materials, high efficiency, and catalytic performance promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

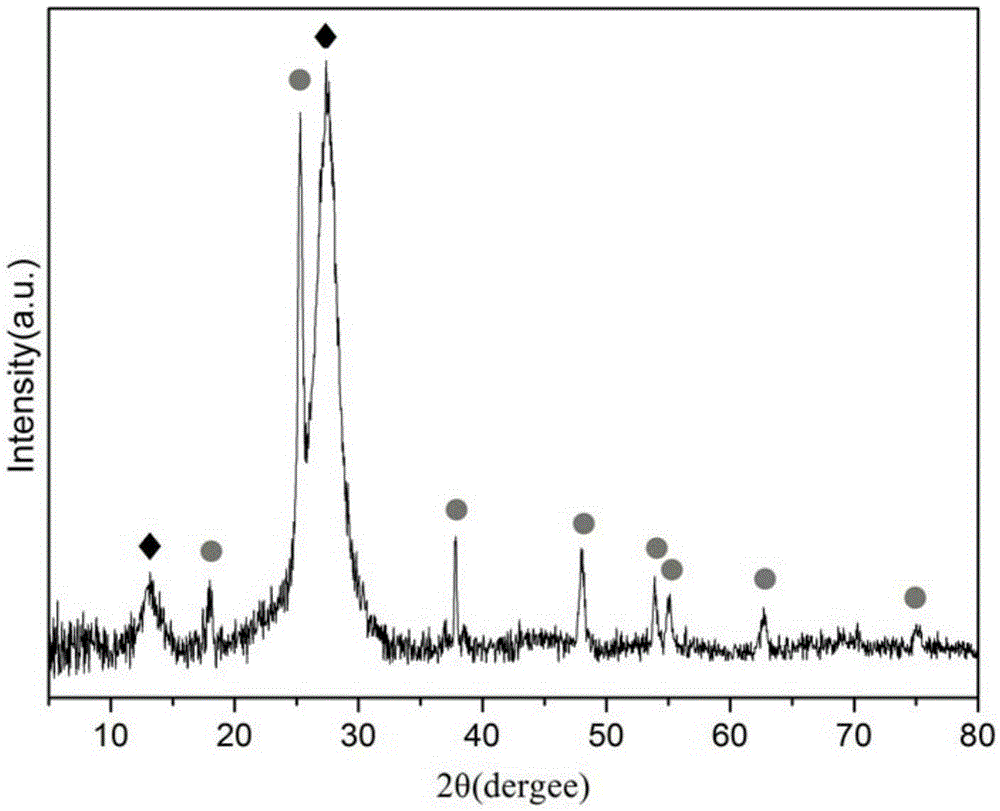

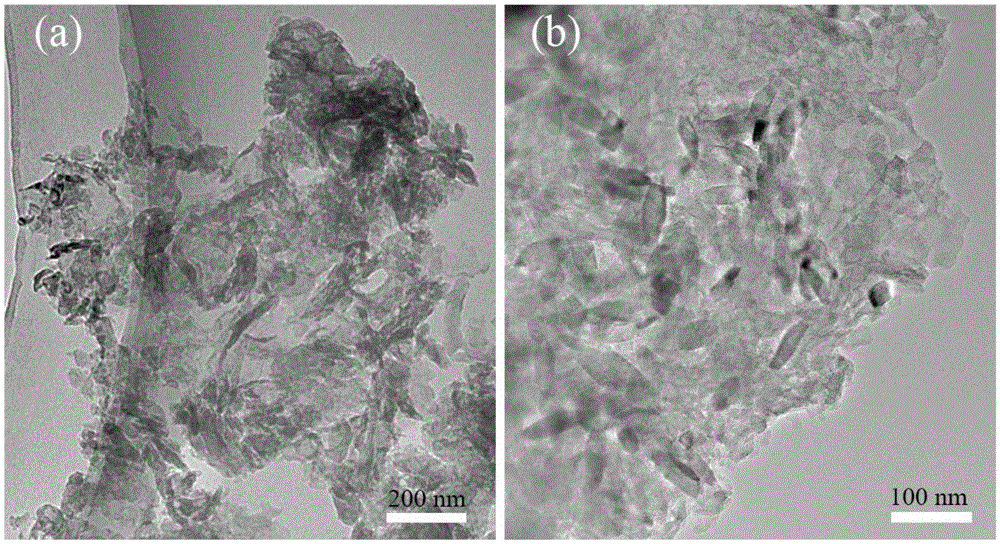

[0019] Specific embodiment one: This embodiment uses an ultrasonic-assisted method to synthesize sheet g-C 3 N 4 With TiO 2 The method of nanorod composite materials is specifically operated as follows:

[0020] 1. Add alcohol solvent and tetrabutyl titanate dropwise to the mixed solution of oleylamine oleate under stirring conditions to obtain a yellow solution, and continue stirring for 30 minutes; where the volume ratio of tetrabutyl titanate to solvent is 1:( 15-25), the volume ratio of oleic acid and oleylamine is 1:(1~2.4);

[0021] 2. Transfer the yellow solution obtained in step 1 to a high-pressure hydrothermal kettle, place it in a blast drying oven, and set the heating temperature to 140-180°C for 16-24 hours;

[0022] 3. Centrifugally wash the product after the reaction in step 2, and then ultrasonically disperse the centrifugal product in absolute ethanol, and repeat the washing for 3 to 5 times; the conditions for centrifugal washing are: the centrifuge rotation speed i...

specific Embodiment approach 2

[0028] Specific embodiment two: this embodiment is different from specific embodiment one in that: the characteristic in step one is that the alcohol solvent is one or more of methanol, ethanol, ethylene glycol, isopropanol and mixed in any ratio The mixed solution. Others are the same as the first embodiment.

specific Embodiment approach 3

[0029] Specific embodiment three: This embodiment is different from specific embodiment one or two in that the volume ratio of tetrabutyl titanate to alcohol solvent in step one is 1: (15-25). Others are the same as the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com