Photocatalyst CN-ZnO and preparation method and application thereof

A photocatalyst and zinc compound technology, applied in the field of photocatalytic materials, can solve the problems of low methylene blue degradation rate, operator casualties, unstable catalytic activity of visible light catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] (1) Accurately weigh 0.125g of zinc acetate with an electronic balance, fully dissolve it in 20ml of deionized water, then add 10g of melamine that has been weighed, and stir the mixed solution vigorously on a magnetic stirrer for 1 hour to make the solution well mixed. The stirred mixture was dried in vacuum at 80°C for 4h;

[0067] (2) Grind the dried mixture, place it in a crucible, cover it, and put it in a muffle furnace for calcination at 520°C for 6 hours, then cool it after calcination, and grind the cooled solid until the D50 particle size is 50nm , to prepare a CN-ZnO catalyst sample, denoted as g-C 3 N 4 -ZnO-6.

Embodiment 2~4

[0069] The method used in Examples 2-4 is similar to that of Example 1, the only difference is that the calcining time in step 2 is 8h, 10h and 12h respectively, and the photocatalysts obtained are respectively recorded as g-C 3 N 4 -ZnO-8, g-C 3 N 4 -ZnO-10 and g-C 3 N 4 -ZnO-12.

experiment example 1

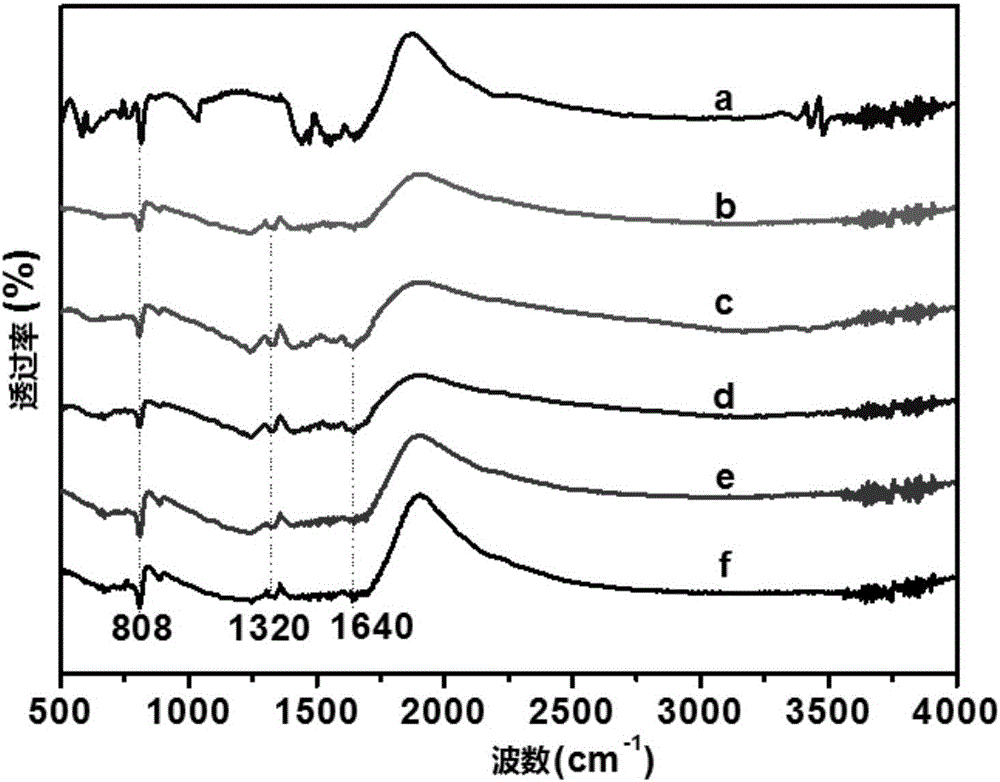

[0076] The infrared spectrometry of experimental example 1 sample

[0077] The samples used in this embodiment are prepared from Examples 1-4 and Comparative Examples 1-2.

[0078] Operation method: Take a small amount of the above-mentioned photocatalyst samples, add them to potassium bromide powder respectively, grind the samples to mix evenly with potassium bromide, press them into thin slices, and use a Fourier transform infrared spectrometer to carry out infrared spectrum characterization of the catalysts. The results are as follows: figure 2 As shown, among them,

[0079] Curve a shows the infrared spectrum curve of the sample made in comparative example 2;

[0080] Curve b shows the infrared spectrum curve of the sample that embodiment 1 makes;

[0081] Curve c shows the infrared spectrum curve of the sample that embodiment 2 makes;

[0082] Curve d shows the infrared spectrum curve of the sample that embodiment 3 makes;

[0083] Curve e shows the infrared spectr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com